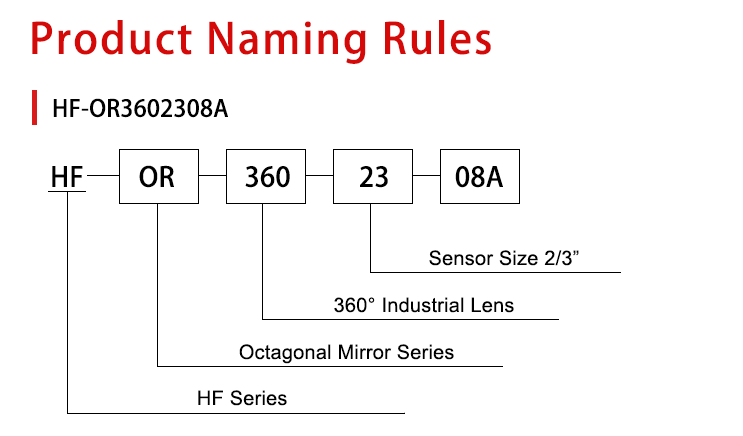

HF-OR3602308A 360° Industrial Lens 2-5mm

|

HIFLY 360 degree Industrial lens is divided into internal and external observations. It detects the internal view or appearance of the measured object in 360 degrees, and transmits HD images in real time. |

|

● Sensor Size: 2/3". |

|

● Working Distance: 2-5mm. |

|

● F/NO: F1.6-16, C-Mount. ● High contrast and excellent imaging effects. ● Suitable suitable for appearance detection, inner wall detection, cylinder and complex structure detection, etc. |

| Model | Sensor Size | F/NO. | Image Size(mm) | Working distance(mm) | Target Dia(mm) | Inspection Height(mm) | Mount |

| HF-OR3601802A | 1/1.8" | F8.0-16 | Ф5.32 | 9-45.4 | 7.5-30 | 5.3-25 | C |

| HF-OR3602303A | 2/3" | F8.0-16 | Ф6.6 | 15-49 | 7.5-30 | 4.2-23.5 | C |

| HF-OR3601204A | 1/2" | F7.0-16 | - | 8-44 | 7-35 | 5-28 | C |

| HF-OR3601305A | 1/3" | F6.0-16 | Ф3.6 | 9.7-46.5 | 7.5-30 | 6.4-25.6 | C |

| HF-IR3602306A | 2/3" | - | - | 2.7-70 | 5-120 | 5-123 | C |

| HF-OR3601207A | 1/2" | F6.0-12 | - | 10-43 | 30-80 | 26.5-46.6 | C |

| HF-OR3602308A | 2/3" | F1.6-16 | Ф6.6 | 2-5 | 0.8-30 | 7.6-17 | C |

| HF-OIR3601809A | 2/3" | F1.6-16 | Ф6.6 | 12.6 | 5-70 | 7.1-26.6 | C |

| HF-OR3601811A | 1/2" | F8.0-22 | - | 15-66 | 5-40 | 5-10 | C |

| Please contact us learn more models! | |||||||

| Model | HF-OR3602308A |

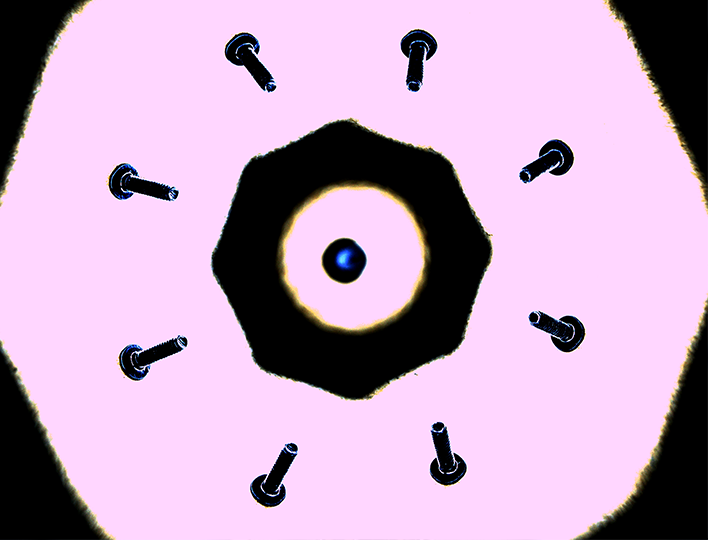

| Type | 360 Degree Industrial Lens-Octagonal mirror |

| Sensor Size | 2/3" |

| Image Size | Ф6.6 |

| WD | 2-5mm |

| F/NO. | F1.6-16 |

| Target Dia | 0.8-30mm |

| Inspection Height | 7.6-17mm |

| Mount | C-Mount |

| Main Material | Aluminum Alloy + optical Glass |

| Color | Black |

| Weight(g) | — |

| Warranty | 2 years |

| Custom Design | Supported |

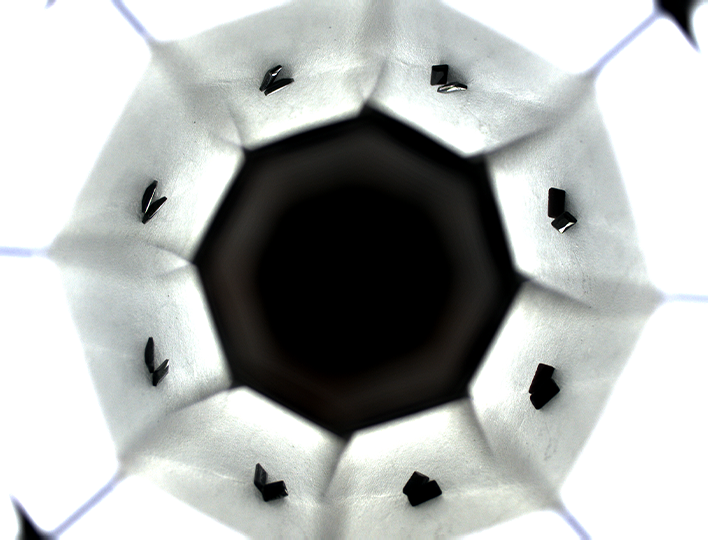

Gem surface defect detection

Octagonal mirror can simultaneously capture the images of the gem from eight directions in a single time. After the algorithm, the images are stitched into a 360° panorama, and the defects such as cracks, cracks and polishing are identified.

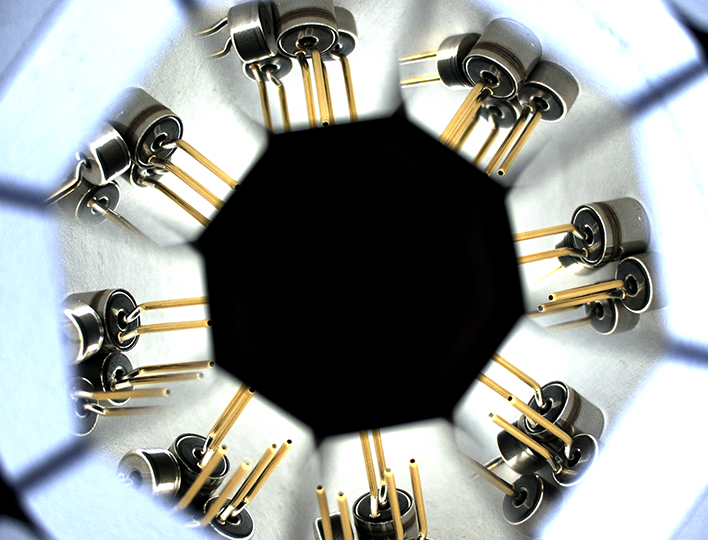

Electric detonator appearance defect detection

The images of eight directions of the electric detonator were taken once and stitched into a 360° panorama by the algorithm. The defects such as cracks, indentation, burr, incomplete closing and electrode pin differences of the shell were effectively identified.

Screw appearance defect detection

Images were taken simultaneously for eight different directions of the screw. The machine vision algorithm was combined to determine whether the pitch was uniform according to the multi-angle thread image. Observe the appearance for defects.

Workpiece appearance character detection

The octagonal mirror divides the cylindrical workpiece into eight views (each mirror covers a range of 45°), and the camera can obtain eight angles of character images in one shot. Through the algorithm, a complete circular character view is stitched to quickly identify whether there is a local missing character.

Q1. Can I have a sample order for 360 Degree Viewing Lens?

A: Yes, sample orders and any orders are acceptable.

Q2. What is the lead time?

A: 3-5 days for sample/small(<50pcs) orders, 1-2 weeks for bulk buying (>50pcs).

Q3. What's your MOQ for the 360 Degree Viewing Lens ?

A: The MOQ is 1pcs.

Q4. What's your shipment term and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 5-7 days by air. Shipping by sea is also acceptable.

Q5. How to place an order for 360 Degree Viewing Lens ?

A: 1. Confirm parameters such as FOV and WD;

2. Confirm the shape, state, material and color of the detected object;

3. Confirm the order and quote;

4. Pay orders and arrange production;

5. Check the product and arrange delivery.

Q6. Do you support private labels?

A: Yes, we do.

Q7: How long is your product warranty?

A: We offer 2-5 years warranty for our products.

Q8: How do you deal with the faulty products?

A: 1, Our products are produced in strict quality control system with a 0.2% defective rate.

2, If non-artificial damage, dysfunction or errors happen during the warranty period, customers can go for repair, replacement or partial/full refund.

HF-OR3602308A(Specifications & Drawings).pdf

download