-

HIFLY 2026 Spring Festival Holiday Schedule

2026/01/28Dear Customers,We sincerely appreciate your continued support and trust this year.As the 2026 Chinese Spring Festival approaches,our holiday arrangementshave been confirmed as follows: - Spring Festival Holiday: February 11-23, 2026. - Resu...

-

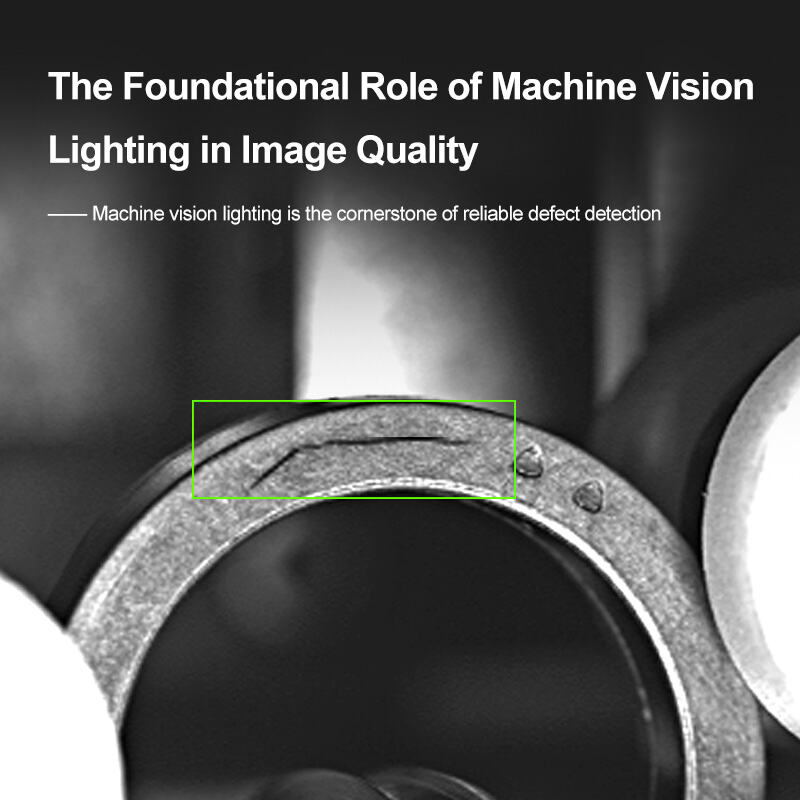

Why Machine Vision Lighting Determines Inspection Accuracy

2026/01/2270% of inspection failures stem from poor lighting—not algorithms. Discover how wavelength, geometry & uniformity drive defect detection accuracy. Optimize now.

-

The Light Source Used For Detecting Characters On The Product Surface

2026/01/21In industrial vision-based surface character inspection (e.g., production dates), coaxial light sources and bar light sources are preferred, and the specific selection should be based on the characters and the material and contrast of the product sur...

-

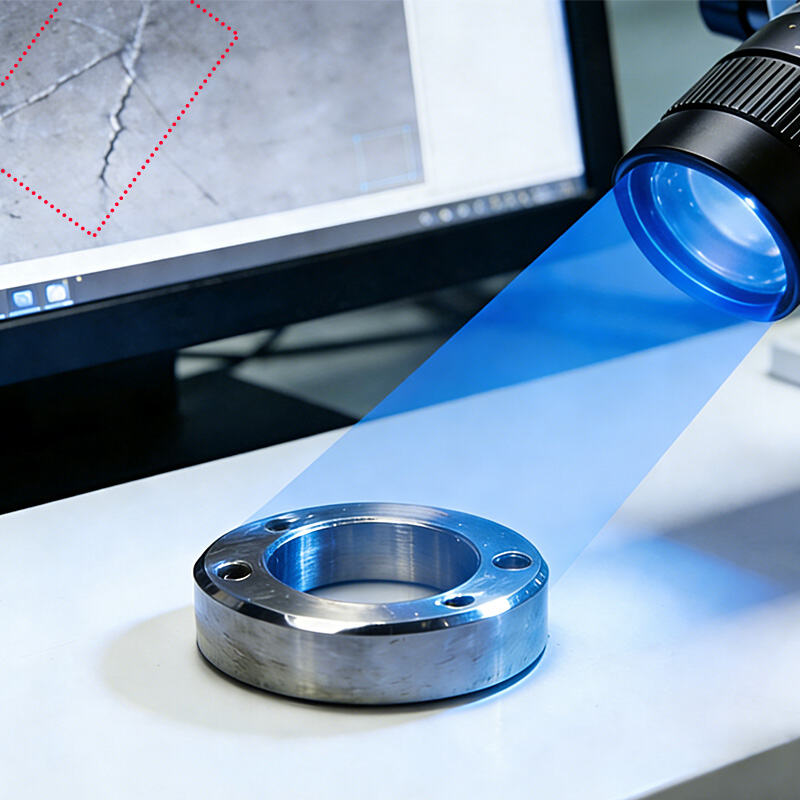

Machine Vision Lens Types Explained: Fixed, Telecentric, Zoom

2026/01/18Which machine vision lens type delivers stability, precision, or flexibility? Compare fixed, telecentric, and zoom lenses for metrology, inspection & ROI. Get expert guidance now.

-

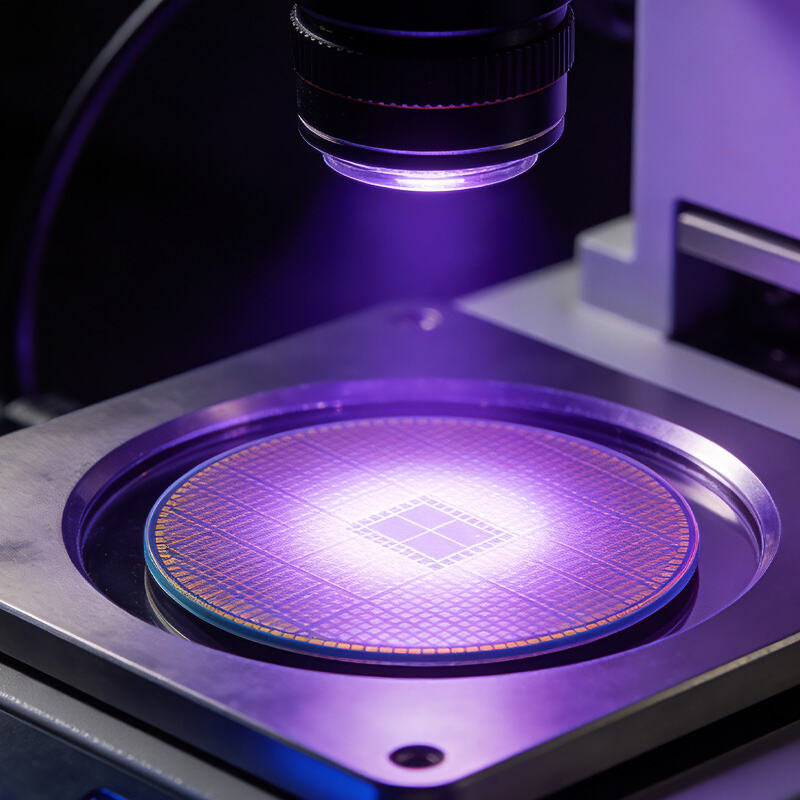

A Brief Introduction and Application Scenarios of UV Cameras

2026/01/14Many people have heard of "infrared cameras," but what functions do their counterparts, "ultraviolet (UV) cameras," have? In daily life, we often encounter problems that are "invisible to the naked eye"—trying to verify anti-counterfeit ...

-

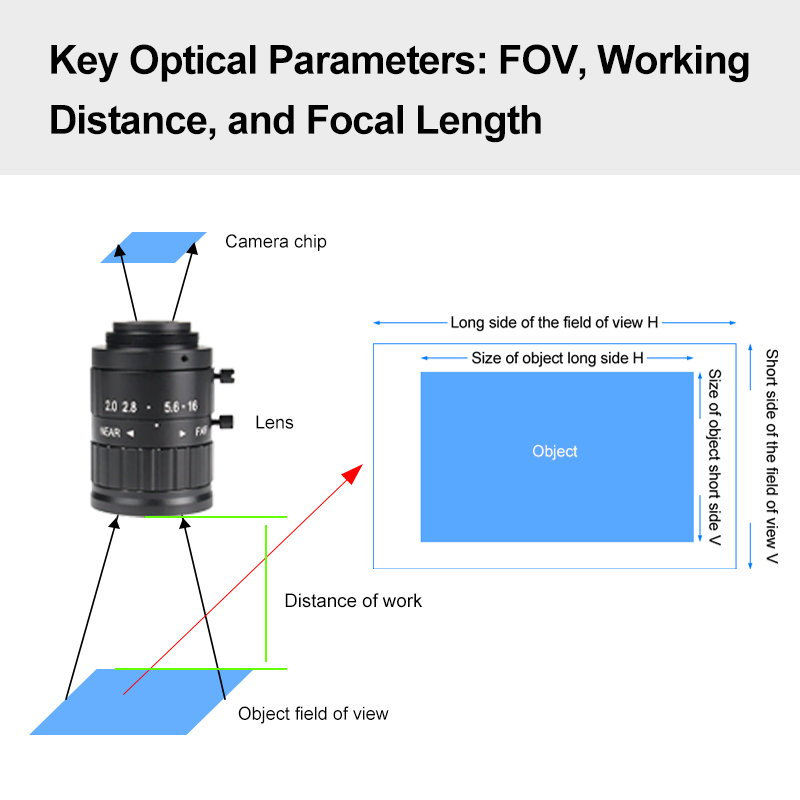

Machine Vision Lens Selection Guide for Industrial Applications

2026/01/13Struggling with blurry inspections or false rejects? Master FOV, working distance, sensor compatibility & MTF to choose the right industrial lens. Get precision results—download guide now.

-

LED Machine Vision Lighting Guide for Automated Systems

2026/01/09Struggling with inspection errors in high-speed automation? Discover 5 proven LED lighting techniques that boost defect detection by 32% and eliminate motion blur. Optimize your machine vision accuracy now.

-

Application of Polarizers and Polarized Lights in Machine Vision Inspection Projects

2026/01/07Machine vision inspection is critical in intelligent manufacturing, but workpiece surface reflection, glare, and uneven illumination often degrade image quality and hinder accurate defect detection. Polarizers and polarized light sources, as key opti...

-

Machine Vision Light Types: How to Select the Best Illumination

2026/01/03Struggling with false rejects or missed defects? Discover how bar, dome, backlight & other machine vision lights boost contrast, SNR & ROI. Get industry-specific benchmarks & selection criteria.

-

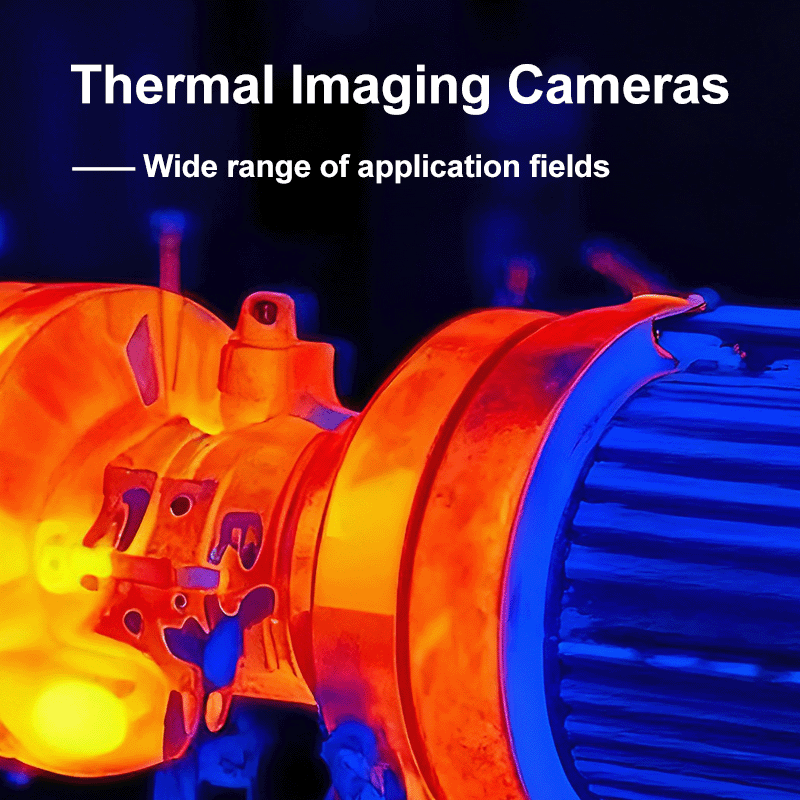

The Application Fields Of Thermal Imaging Cameras

2025/12/28The core function of a thermal imaging camera is to generate thermal images by detecting the infrared radiation emitted by objects, with applications covering four core areas: industrial testing, public security, medical and health care, and civilian...

-

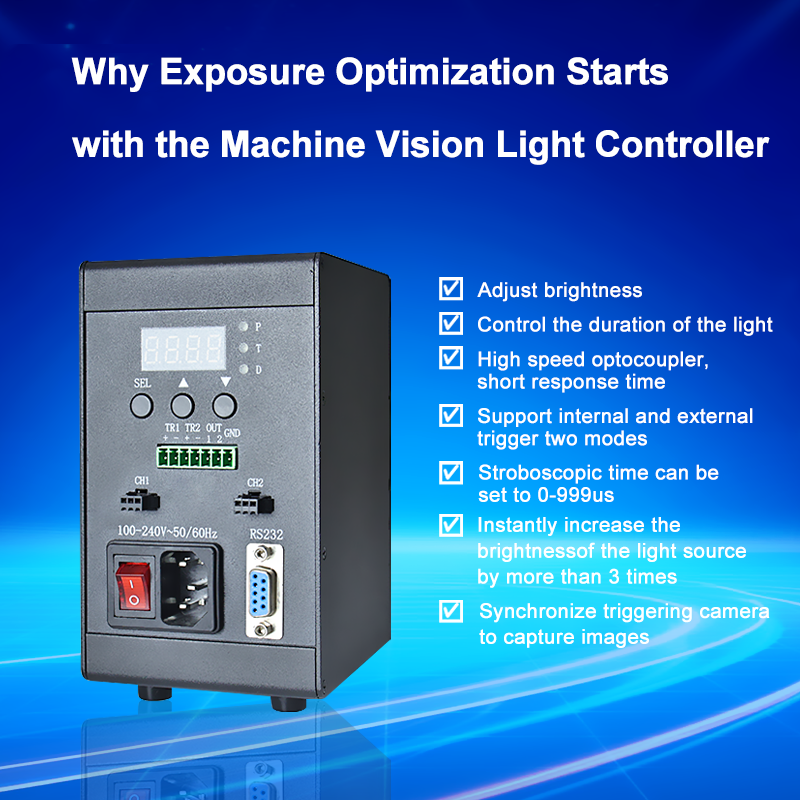

How to Optimize Exposure Using a Machine Vision Light Controller

2025/12/23Struggling with blurry images or poor contrast on fast production lines? Discover how machine vision light controllers boost exposure control, SNR, and defect detection—get actionable insights now.

-

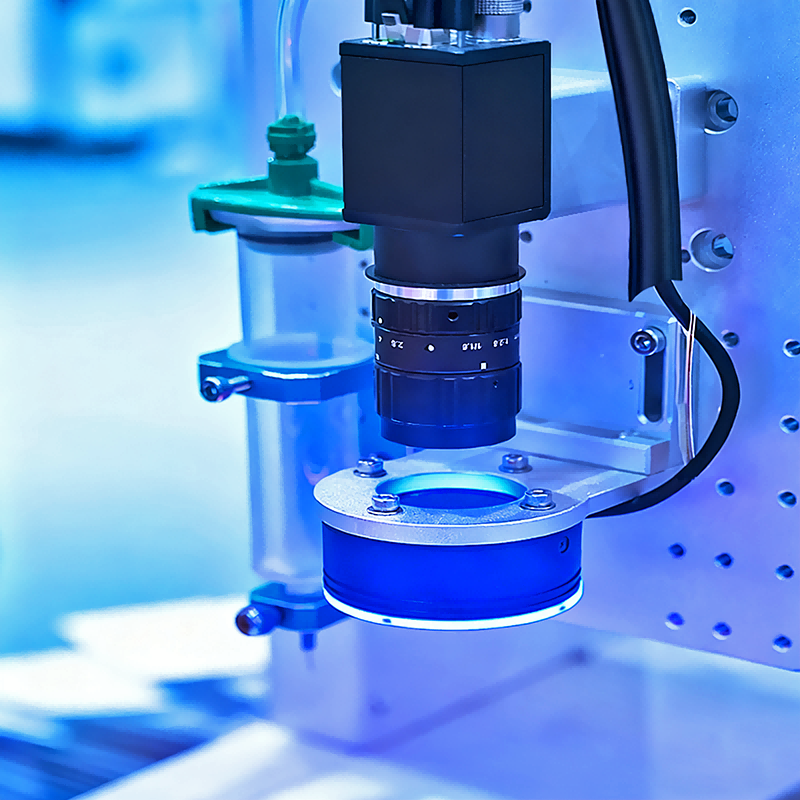

Why Has Machine Vision Become the Mainstream in Industrial Quality Inspection?

2025/12/21Someone may wonder, "Why has machine vision become the mainstream in industrial quality inspection?" Traditional manual inspection is often plagued by issues: inability to see minute defects, failure to keep up with high-speed production li...