Machine Vision System for Detecting Scratches on Transparent Glass Bottles

In the production of transparent glass bottles, ensuring product quality is of utmost importance. Scratches on glass bottles can not only affect their aesthetic appearance but also potentially compromise their structural integrity and usability. Traditional manual inspection methods are time-consuming, labor-intensive, and prone to human error. As a result, machine vision systems have emerged as a reliable and efficient alternative for detecting scratches on glass bottles.

Products Used in the Machine Vision System

Lighting Systems

Proper lighting is essential for enhancing the visibility of scratches on glass bottles. Different lighting techniques can be used depending on the characteristics of the glass bottles and the type of scratches to be detected.

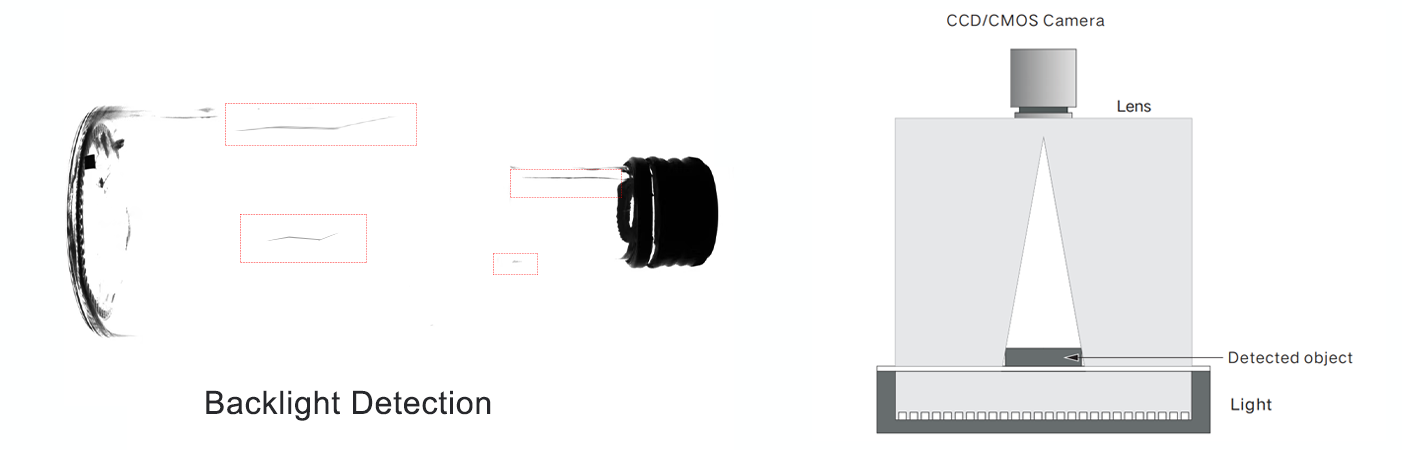

Backlighting is a commonly used method. A bright, uniform backlight source, such as an LED light panel, is placed behind the glass bottle. When light passes through the transparent glass, a scratch, which is a disruption in the smooth surface, will block or scatter the light. This makes the scratch appear as a dark line or area against the bright background, making it highly distinguishable. This technique is particularly effective for detecting scratches that penetrate through the glass or are relatively deep, as they create a more obvious obstruction to the light flow.

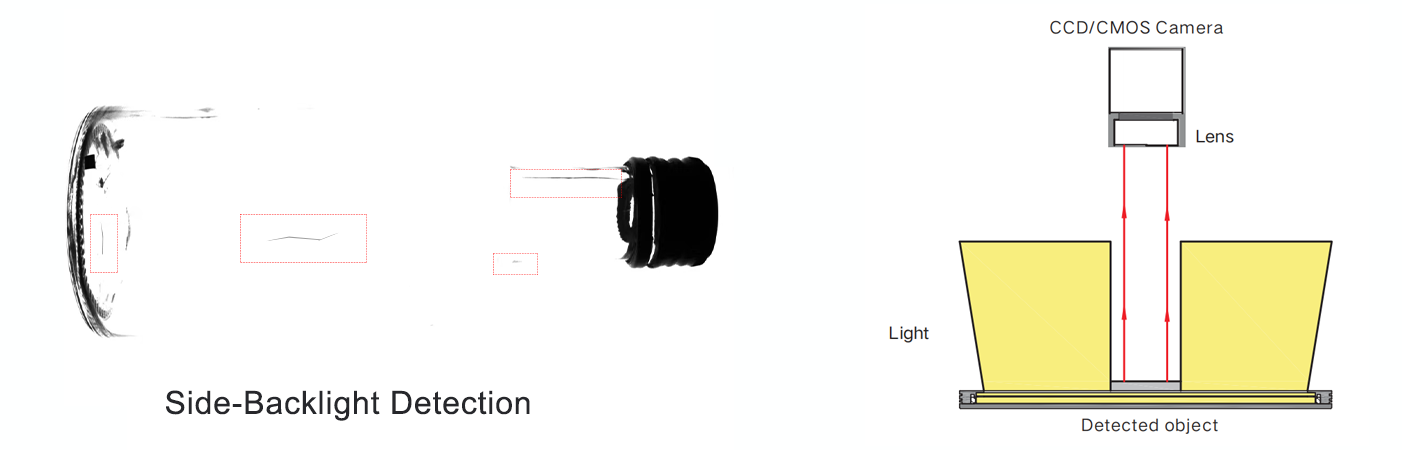

Side-lighting is another effective approach, especially for detecting shallow scratches on the surface of the glass bottle. By positioning the light source at an angle to the side of the bottle, the light hits the surface and shallow scratches cast shadows. These shadows enhance the contrast between the scratch and the surrounding smooth surface, making even minor scratches visible to the camera. The angle of the side light is crucial; too steep an angle may cause excessive glare, while a too shallow angle may not create distinct enough shadows.

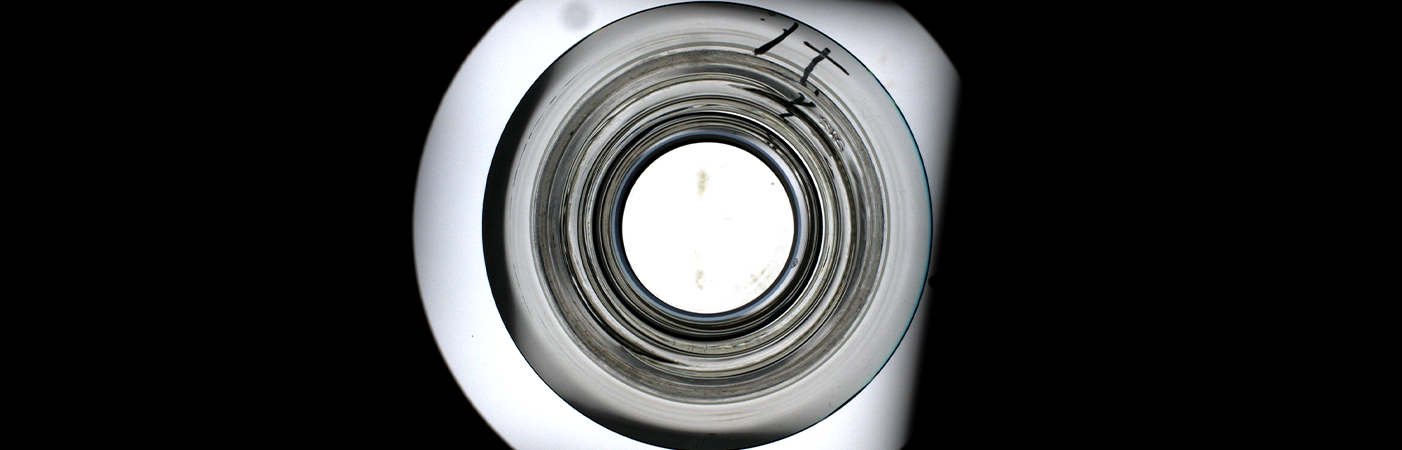

Ring lights, which provide 360-degree illumination around the lens, are also widely utilized. They emit light evenly around the camera's field of view, ensuring that the entire surface of the glass bottle is illuminated uniformly. This helps in avoiding uneven lighting that could mask scratches in darker areas. Ring lights are beneficial for detecting scratches on curved surfaces of glass bottles, as they can follow the contour of the bottle and provide consistent lighting across different parts of the surface.

Polarized lighting is employed to address issues related to glare and reflections. Glass is highly reflective, and regular lighting can cause unwanted reflections that obscure scratches. Polarized lights, combined with polarizing filters on the camera lens, can reduce or eliminate these reflections. The polarized light waves vibrate in a specific direction, and the filter on the camera only allows light waves vibrating in that direction to pass through, filtering out the scattered, reflective light and making scratches more visible.

Problems Encountered in the Detection Process

Reflection and Refraction of Light

One of the major challenges in detecting scratches on transparent glass bottles is the reflection and refraction of light. Glass is a highly reflective and refractive material. When light hits the surface of a glass bottle, it can reflect in multiple directions, creating glare and specular highlights that can obscure the visibility of scratches. Additionally, light passing through the glass can be refracted, causing the appearance of scratches to be distorted. This problem becomes more pronounced when using certain lighting setups. For example, if the lighting angle is not optimized, the reflected light from the smooth surface of the glass bottle may be much stronger than the light scattered by the scratches, making it difficult for the camera to capture clear images of the scratches.

Variability in Glass Bottle Surface and Scratch Characteristics

Glass bottles can have a wide range of surface characteristics, including smoothness, texture, and color. Some glass bottles may have embossed patterns or labels, which can add complexity to the scratch detection process. Moreover, scratches themselves can vary in size, shape, depth, and orientation. Small, shallow scratches may be easily overlooked, especially if they are located in areas with complex surface features. Deep scratches may have different optical properties compared to shallow ones, requiring different lighting techniques for accurate detection. Additionally, the orientation of scratches can affect how they interact with light and how they are captured by the camera. Scratches that are parallel to the lighting direction may be less visible than those perpendicular to it.

Difficulty Analysis

Lighting Setup and Optimization

Achieving the optimal lighting setup is a significant difficulty. With various lighting types available, determining which one or combination is most suitable for a specific type of glass bottle and scratch characteristics is challenging. It requires extensive testing and adjustment. For example, a glass bottle with a highly curved surface may require a combination of ring lights and side lights to ensure all areas are properly illuminated, while a bottle with a smooth, flat surface may work well with backlighting. Moreover, the intensity of the light needs to be precisely controlled. Too much light can cause overexposure, washing out the details of scratches, while too little light can make scratches indistinguishable from the background.

Conclusion

Machine vision systems offer a promising solution for detecting scratches on transparent glass bottles, with lighting systems playing a crucial role in the process. By using appropriate lighting techniques such as backlighting, side-lighting, ring lights, and polarized lighting, these systems can enhance the visibility of scratches and improve the quality control in glass bottle production. However, the detection process is not without its challenges, including issues related to light reflection and refraction, variability in glass bottle and scratch characteristics, and complex production environments. Overcoming these challenges requires careful lighting setup and optimization, system calibration and integration, and maintenance. As technology continues to advance, further improvements in lighting systems and their integration into machine vision setups for glass bottle scratch detection can be expected, leading to more efficient and accurate quality control in the glass manufacturing industry.