How to Choose Appropriate Ring Light Source

Choosing a suitable industrial ring light requires considering specific application scenarios and inspection needs, with a focus on the following core factors:

1. Light Source Wavelength (Color)

Select based on the material and surface characteristics of the object to be inspected:

White: Versatile, suitable for most conventional inspections (such as appearance defects, size measurement).

Red/Near-infrared: Good penetration, suitable for detecting transparent/translucent objects (such as glass, films) or reducing surface reflections.

Blue/Ultraviolet: Can enhance detail contrast on highly reflective surfaces (such as metals, plastics), suitable for detecting tiny defects.

Green: Works well for inspecting PCB boards and electronic components.

2. Inner and Outer Diameter Sizes

Need to match the installation space of inspection equipment (such as lenses, cameras):

The inner diameter must be larger than the lens diameter to avoid blocking the field of view;

The outer diameter must adapt to the space constraints of the inspection station while ensuring the illumination range covers the inspection area.

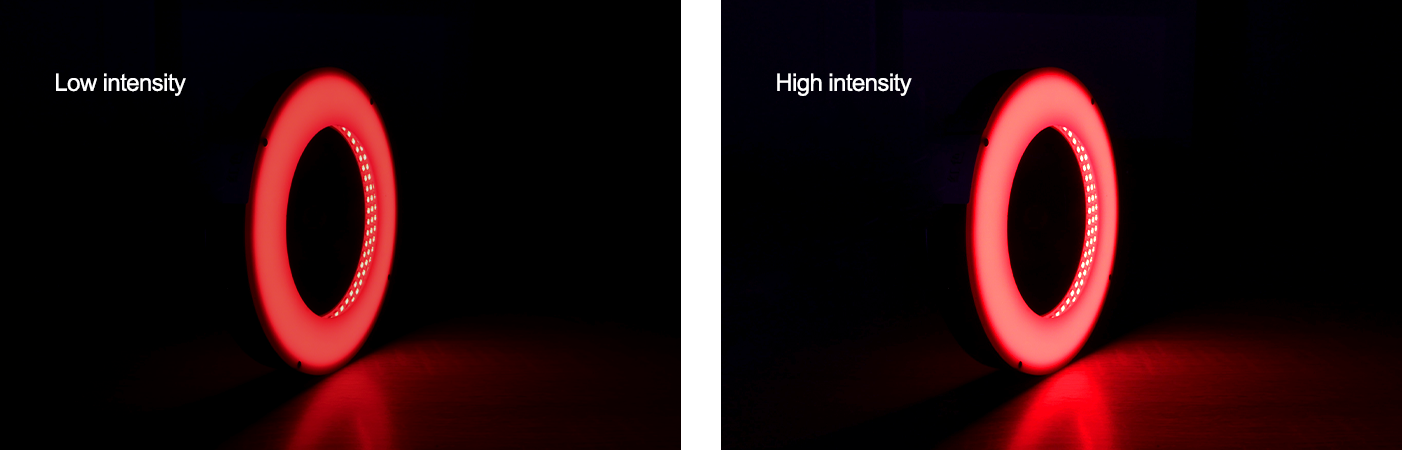

3. Light Intensity and Uniformity

Intensity: Choose according to the reflectivity of the object to be inspected and the camera's exposure time requirements. For highly reflective objects, the intensity can be reduced; for low-reflective objects, the intensity needs to be increased (some light sources support brightness adjustment).

Uniformity: Prioritize light sources with uniform emission to avoid inspection errors caused by uneven illumination (such as blurred edges, local overexposure).

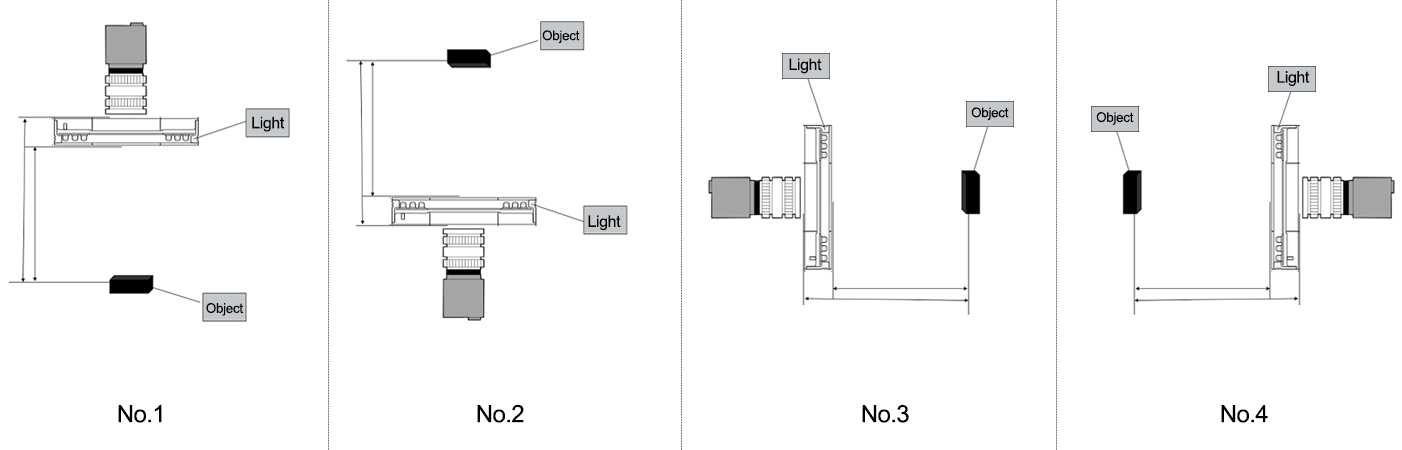

4. Working Distance

That is, the distance from the light source to the object to be inspected, which needs to be adjusted in conjunction with the lens focal length:

For short-distance inspection (such as small parts): Choose a small-angle light source to concentrate light and enhance details;

For long-distance inspection (such as large-area objects): Choose a large-angle light source to ensure the illumination range.

5. Installation and Compatibility

Interface: Confirm that the electrical interface of the light source matches that of the equipment (such as controllers, cameras) (such as USB, DC interfaces).

Installation method: Choose fixed or adjustable (such as angle-rotatable) according to the station design to ensure stable installation and easy debugging.

6. Environmental Adaptability

If used in special environments (such as high-temperature, humid, or dusty workshops), select light sources with waterproof, dustproof, and temperature-resistant properties (such as IP65 protection level).

7. Controller Functions

In some scenarios, the light source needs to support brightness adjustment and strobe control (synchronized with camera exposure) to avoid motion blur. In such cases, a controller with corresponding functions must be matched.

By clarifying inspection targets (such as defect types, object materials), equipment parameters (lens, working distance), and environmental conditions, the selection range can be narrowed down. If necessary, the lighting effect can be verified through sample tests before finalizing the choice.