Select The Size Of Machine Vision Light

Machine vision technology is an important pillar of modern industrial automation and smart manufacturing, widely used in inspection, navigation, quality control and other fields. Among them, 2D, 2.5D and 3D vision technologies are three core technologies, each with different characteristics and applicable scenarios.

I. Background

When evaluating a visual light source scheme, it is an important consideration to reserve a proper space for the visual light source.

During the evaluation, if the light source test and verification are not done in advance, there may be a problem that the reserved space is too small in the later stage. That is, the actually available light source is often larger than the originally reserved space, thus affecting the project; if a small installable light source is adopted to meet the size requirement, it is very likely that the imaging quality is poor and the irradiation effect is unsatisfactory due to the mismatch of the light source, thus affecting the progress of the entire project. In the end, it is still necessary to modify the installation space according to the actual size of the light source, and the whole process is time-consuming and laborious.

Therefore, it is particularly important to do a good job in the evaluation of light source selection in the early stage when evaluating the visual scheme. At present, most visual schemes first carry out lighting tests to determine the size and height of the light source, and then design other parts, which will be of great help to the smooth development of the entire project in the later stage.

II. Selection Cases

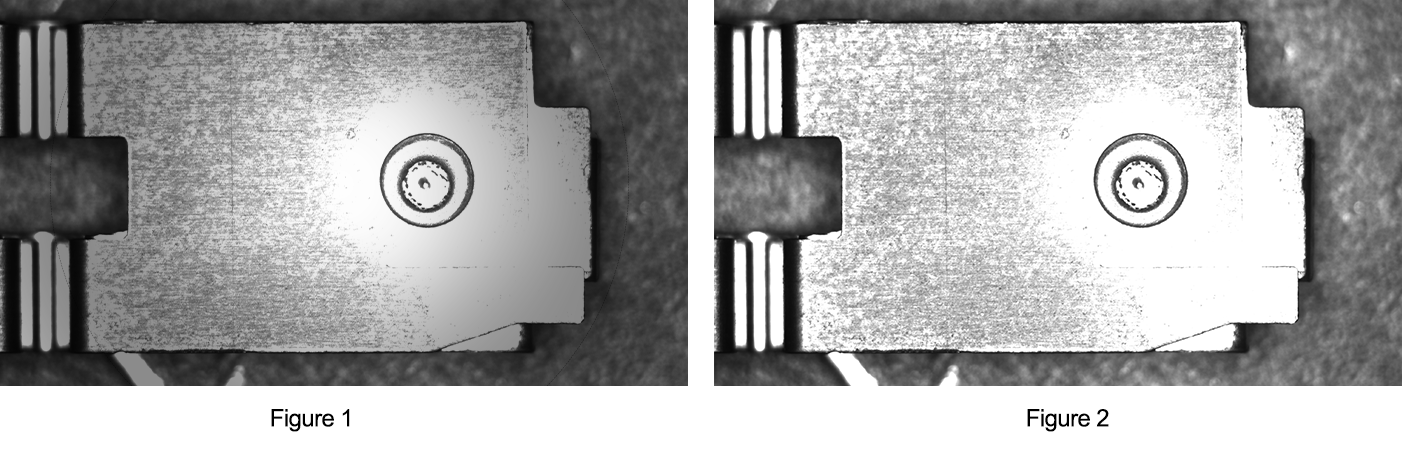

The following are two images comparing the imaging effects of large and small light sources: Figure 1 shows that due to the small light source, the light spot cannot cover the field of view; Figure 2 shows that the light source size is appropriate, which can cover the entire field of view, with uniform overall effect and obvious detection features.

How can we select a light source of appropriate size without initial lighting tests? After obtaining the test samples, we need to understand the detection features, judge the optical path type and color of the light source, and after selecting these, we can judge the required size of the light source.

There are mainly three points as reference basis. The first point: irradiation mode, there are two types of irradiation modes, one is front irradiation, and the other is bottom backlight irradiation; The second point: lens selection, there are two types of lenses, namely FA lens and telecentric lens; The third point: the working distance and field of view size of the light source structure.

III. Irradiation Mode

Judging from the front irradiation mode whether the detection product surface is smooth and reflective, the non-reflective surface has low requirements on the size of the light source, and a light source about 1/2 of the field of view is sufficient.

Focusing on the reflective surface as an example to judge how to select the size of the light source, first of all, it is necessary to detect the features on the reflective surface, and light spot should cover the entire field of view and form a uniform image, which will provide better contrast.

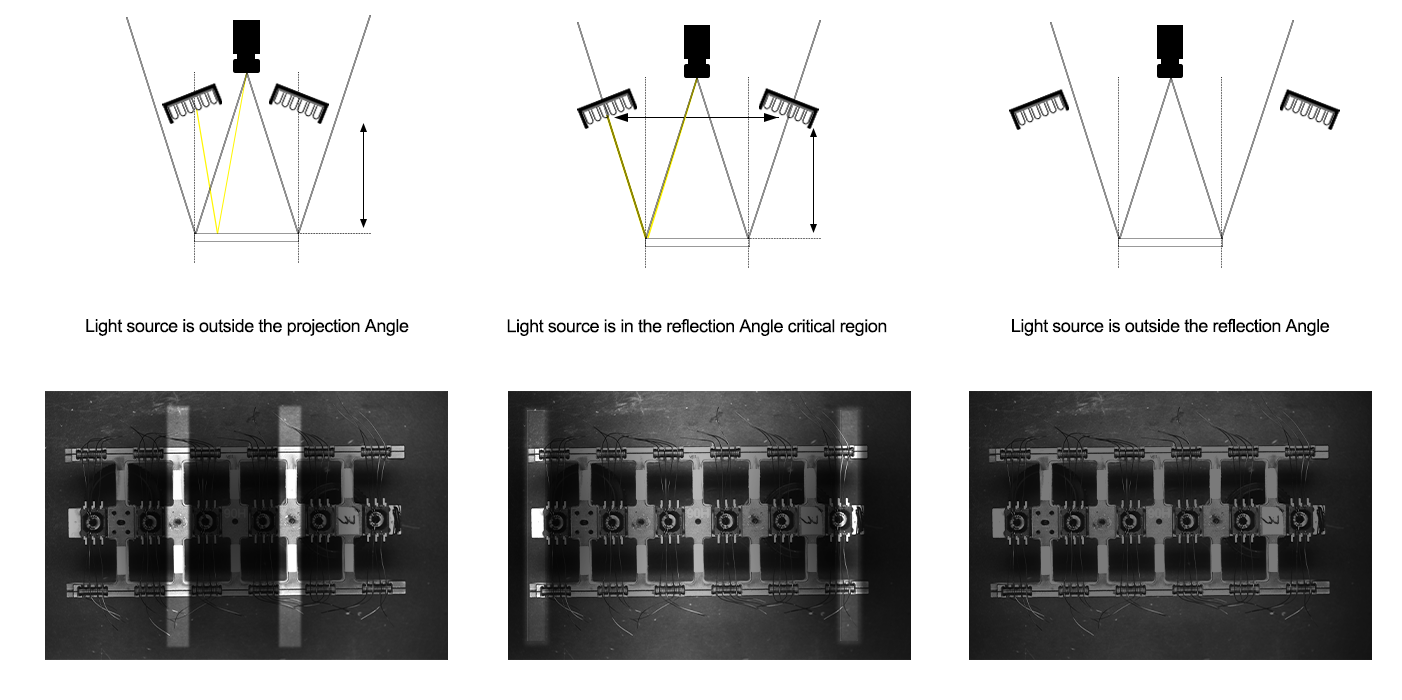

At the same time, three parameters should be known: the size of the camera's target center, the working distance from the camera to the detection surface, and the size of the field of view (the length and width of the field of view correspond to the length and width of the camera chip). Secondly, if the lens is an FA lens, it is also necessary to know the included angle parameter. In this way, the projection angle and reflection angle of the camera lens can be obtained, as shown in the following figures (Figure 3, Figure 4, Figure 5). It can be seen that the projection and reflection form a W-shaped figure. If the light source is outside the projection angle (as shown in Figure 3), there will be light spots in the reflection angle; If the light source is at the critical position of the reflection angle (as shown in Figure 4), the light spot will be seen on the edge of the imaging field of view; Only when the light source is outside the reflection edge (W) (as shown in Figure 5) can it be a uniform imaging effect diagram.

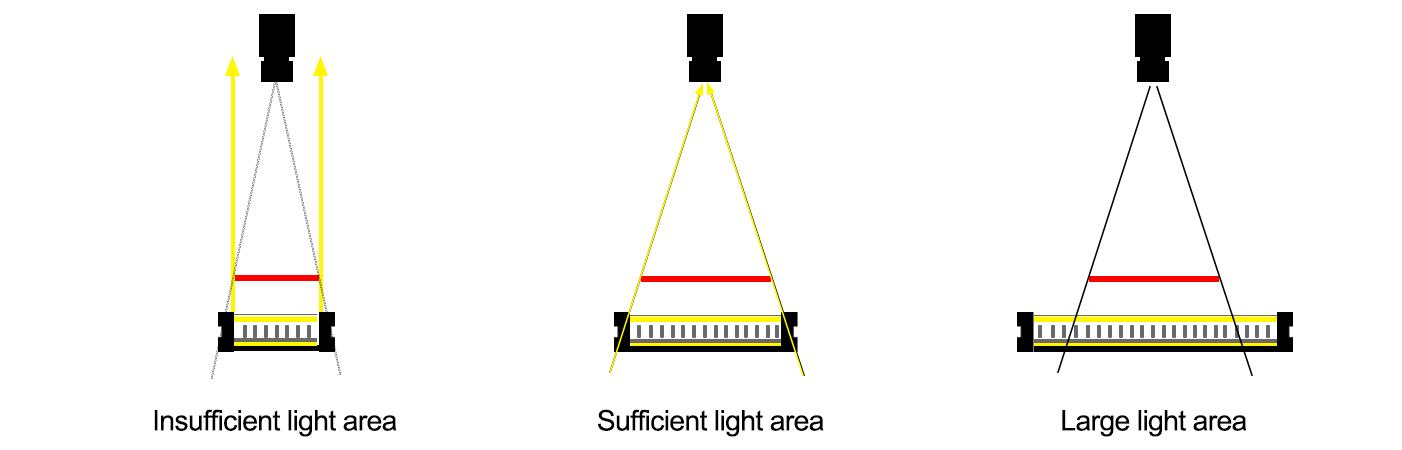

The same applies to bottom backlight irradiation, but there is no need to calculate the reflection angle. The farther the light source is from the detection surface, the larger the extended width distance of the projection angle. When selecting backlight for FA lens, it can be calculated and evaluated in this way. As shown in the following figure:

IV. Lens Selection

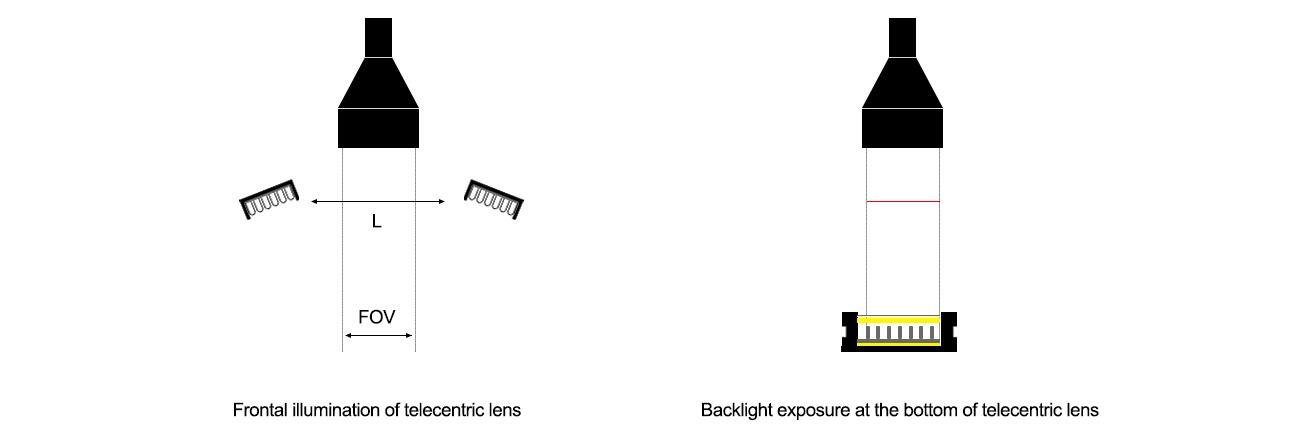

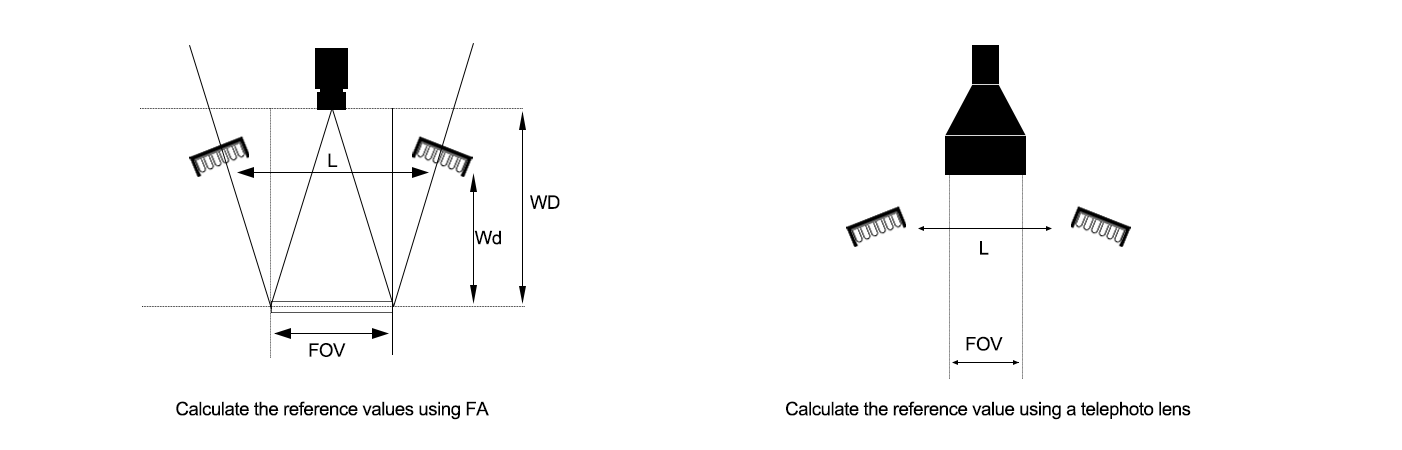

The above two irradiation modes only mention the FA lens, and the pictures and texts also take the FA lens as an example for reference. Then there is another type of lens that needs to be explained, that is, the commonly used telecentric lens. The telecentric lens is basically of the parallel optical path type, so when selecting the size of the light source with the telecentric lens, we only need to be slightly larger than the actual field of view. As shown in the following figure:

V. Working Distance and Field of View Size of Light Source Structure

After knowing the camera target center and working distance, lens angle, light source working distance and field of view, the size of the light source can be determined by calculation. At the same time, software such as CAD can be used to draw graphics according to the parameters, so as to intuitively see where the light spot of the light source is and determine whether the size of the selected light source is appropriate. As shown in the following figure:

When the lens is an ordinary FA lens, the relationship between the light source working distance Wd and the surface light length L can be obtained from the characteristics of similar triangles:

WD/(WD+wd)=FOV/L

When the lens is a telecentric lens, the installation position of the selected light source only needs to ensure that L > FOV.

VI. Conclusion

In the machine vision inspection scheme, the selection of visual light source is an important part. The correct selection of the light source scheme is conducive to the smooth completion of the entire vision system, and a suitable light source can effectively save costs and installation space of the mechanism.