Machine Vision in Liquid Level Detection

In industrial automation, accurate liquid level detection is critical for ensuring product quality, process efficiency, and operational safety. Machine vision, as a non-contact, high-precision technology, has emerged as a powerful solution for liquid level inspection. This article explores the key components of machine vision systems for liquid level detection and their practical applications across industries.

Core Components of Machine Vision Systems for Liquid Level Detection

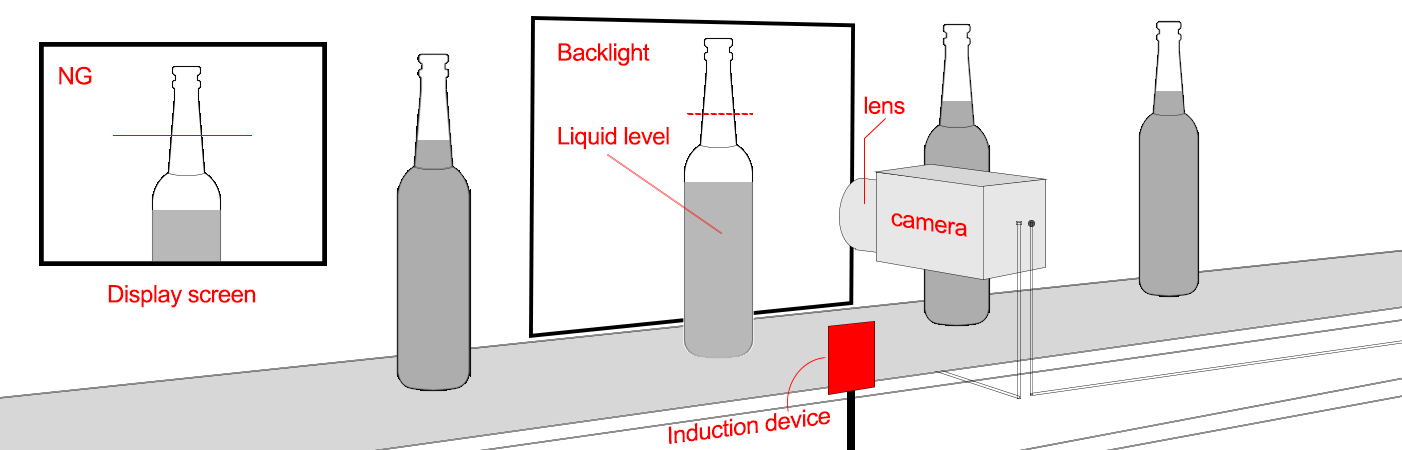

Cameras: Capturing Precise Images

The camera is the system’s "eye," capturing images of the liquid surface. For liquid level detection, resolution (5MP to 20MP for subtle variations) and frame rate (60+ fps for high-speed lines) are key. CCD sensors excel in low light, while CMOS sensors offer speed for high throughput. Global shutters prevent distortion with moving containers.

Lenses: Focusing on Accuracy

Lenses ensure sharp focus on the liquid level, with choices based on working distance, field of view (FOV), and magnification. Narrow FOV and high magnification suit small containers like vials. Telecentric lenses are ideal, as they minimize perspective distortion, keeping liquid level measurements consistent despite slight container position shifts.

Lighting: Illuminating the Liquid-Gas Interface

Lighting creates contrast between liquid, container, and air. Backlighting works for transparent containers, using a rear light source to silhouette the liquid level. For opaque or irregular containers, coaxial lighting reduces surface reflections. Colored LEDs enhance contrast with colored/reflective liquids, and diffusion avoids glare.

Image Processing Software: Analyzing the Data

Specialized software processes images to determine liquid levels. Algorithms detect edges, measure distances between reference points (e.g., container top and liquid surface), and compare against thresholds. Advanced systems handle challenges like curved menisci or bubbles with filters, pattern recognition, or machine learning for adaptability.

Practical Applications of Machine Vision Liquid Level Detection

1. Beverage and Food Industry

In beverage bottling plants, machine vision systems inspect fill levels in bottles of water, soda, or juice at speeds up to 1,000 bottles per minute. Cameras mounted above or beside conveyor belts check for underfills (which risk customer dissatisfaction) and overfills (which cause spillage and waste). For example, a leading soft drink manufacturer implemented a vision system using 12MP cameras and backlighting to ensure fill levels in plastic bottles were consistent within ±0.5mm, reducing product waste by 3% annually.

2. Pharmaceutical and Medical Devices

Pharmaceutical production demands strict adherence to fill levels in vials, syringes, and IV bags to ensure dosage accuracy. Machine vision systems here must handle small containers and transparent liquids while complying with regulatory standards (e.g., FDA guidelines). A pharmaceutical company producing insulin pens uses telecentric lenses and coaxial lighting to detect fill levels in 1mL syringes, achieving a precision of ±0.02mm. This eliminates manual inspections, reduces human error, and accelerates batch validation.

3. Chemical and Petroleum Industry

In chemical processing, accurate liquid level monitoring prevents overflows of hazardous substances and ensures proper mixing ratios. Machine vision systems equipped with ruggedized cameras (resistant to dust, moisture, and corrosive fumes) inspect large tanks or drums containing acids, solvents, or fuels. For instance, an oil refinery uses thermal imaging cameras alongside visible-light systems to detect liquid levels in high-temperature storage tanks, where traditional sensors fail due to extreme heat.

4. Automotive and Aerospace

In automotive manufacturing, machine vision checks the fill levels of fluids such as engine oil, brake fluid, and coolant in vehicle components. For example, during radiator assembly, cameras verify that coolant levels meet specifications before sealing, preventing leaks and ensuring engine performance. In aerospace, the technology inspects hydraulic fluid reservoirs in aircraft, where precision is critical for safety.

Advantages Over Traditional Methods

Machine vision offers several key benefits for liquid level detection:

Non-contact measurement: Eliminates the risk of contamination, making it suitable for sterile environments (e.g., pharmaceuticals).

High speed and accuracy: Handles fast-moving lines and achieves sub-millimeter precision.

Versatility: Adapts to various container shapes, sizes, and liquid types with minimal reconfiguration.

Data integration: Provides real-time data for process optimization and quality control reporting.

Conclusion

Machine vision has revolutionized liquid level detection by combining high precision, speed, and flexibility. By selecting the right cameras, lenses, and lighting systems, industries can overcome the limitations of traditional methods and ensure consistent product quality. From beverage bottling to aerospace manufacturing, the technology continues to drive efficiency and reliability in critical processes, making it an indispensable tool in modern automation.