Industrial 3D Camera Calibration: What You Need to Know

Understanding 3D Camera Calibration in Industrial Applications

In industrial automation, robotics, quality inspection, and advanced manufacturing, precision is non-negotiable. A 3D camera serves as the eyes of a system, capturing detailed spatial data for measurement, positioning, and decision-making. However, no matter how advanced the hardware, a 3D camera’s measurements are only as accurate as its calibration. Industrial 3D camera calibration is the process of mathematically aligning the camera’s captured data with real-world coordinates. This ensures that depth maps, point clouds, and 3D models reflect actual dimensions, angles, and positions. Without calibration, even the most sophisticated camera can produce data riddled with distortions and errors.

Why Calibration Is Crucial ?

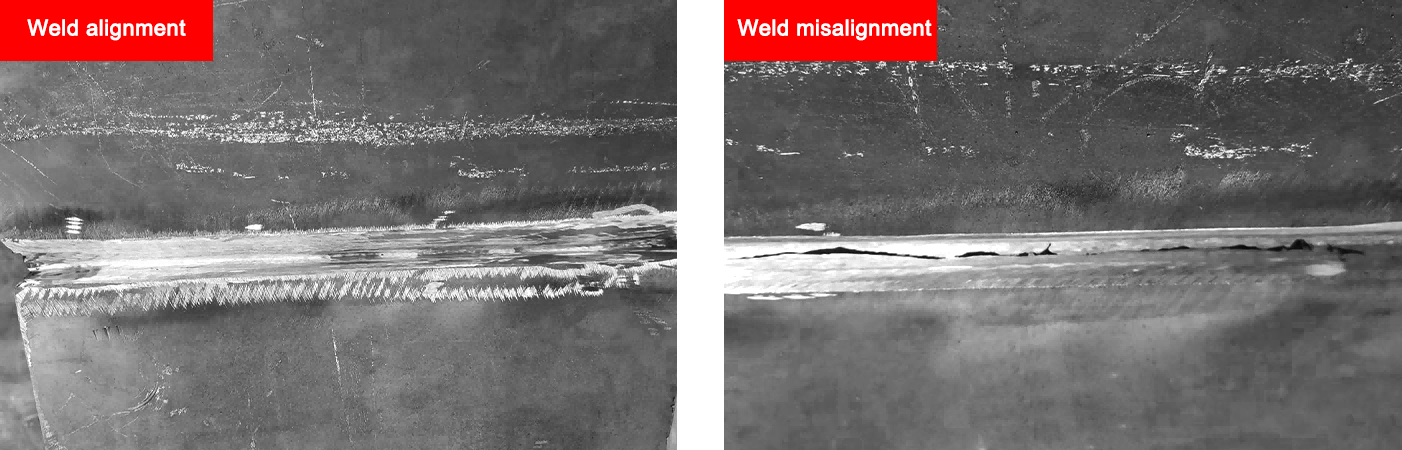

In many industrial settings, tolerances are measured in microns or fractions of a millimeter. A miscalibrated 3D camera can result in inaccurate part measurements, faulty robotic arm placements, or failed quality inspections. For instance, in automated welding, a poorly calibrated camera may misinterpret an object’s position, causing misaligned welds. In high-speed conveyor inspections, a small deviation in depth perception can lead to incorrect pass/fail decisions. Calibration not only improves accuracy but also ensures repeatability—critical for high-volume production where consistency is key.

How Industrial 3D Camera Calibration Works ?

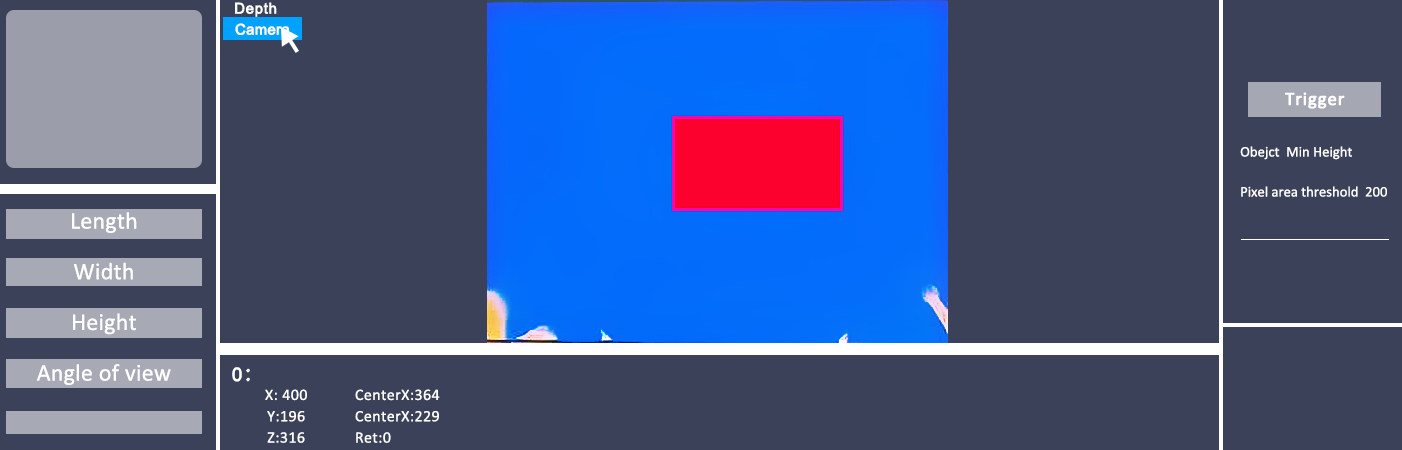

Calibration typically involves determining intrinsic and extrinsic parameters.

- Intrinsic parameters include the focal length, optical center, and lens distortion coefficients. These define how the camera’s internal optics process light.

- Extrinsic parameters describe the camera’s position and orientation relative to a known coordinate system or calibration object.

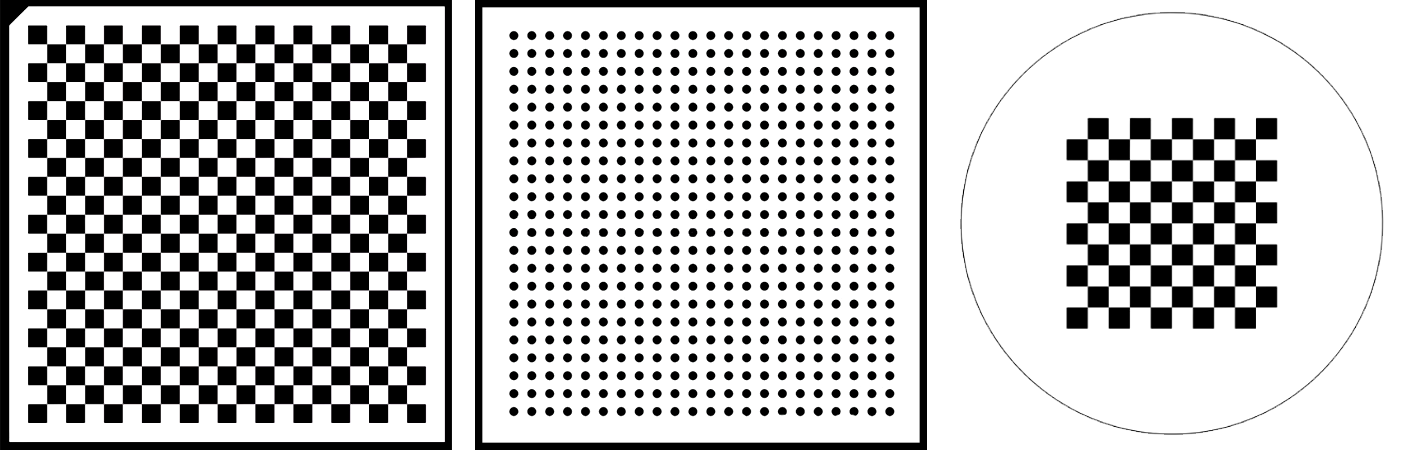

The process often uses calibration targets such as checkerboard patterns, dot grids, or structured light patterns. The 3D camera captures multiple images of the target from different angles. Specialized software then analyzes these images to calculate the precise relationships between the camera’s raw pixel data and real-world measurements. This transformation ensures that each point in a captured scene is correctly mapped to its actual physical location.

Common Calibration Challenges

Industrial environments pose unique calibration challenges. Vibrations from heavy machinery can shift camera positions over time. Temperature fluctuations can cause lens materials to expand or contract, subtly altering optical properties. Dust, grease, and environmental contaminants can obscure calibration targets or interfere with laser and structured light projections. Furthermore, cameras mounted on robotic arms face constant movement, requiring frequent recalibration to maintain accuracy. Addressing these challenges often requires robust mounting solutions, controlled lighting, and regular maintenance schedules.

Static vs. Dynamic Calibration

In industrial 3D camera systems, calibration can be static or dynamic.

- Static calibration is performed once during installation or after major maintenance. The camera remains fixed in position, and the calibration holds until physical changes occur.

- Dynamic calibration involves continuous or periodic recalibration during operation. This is common in robotic systems, where the camera’s position changes with every task. Automated calibration routines allow the system to quickly re-align itself without manual intervention, maintaining accuracy in fast-paced environments.

Tools and Technologies for Calibration

The calibration process relies on both hardware and software tools. Calibration boards with precise geometric patterns are essential for accuracy. Industrial-grade tripods or mounts reduce vibration and movement during calibration. On the software side, manufacturers often provide proprietary calibration programs tailored to their camera models. Third-party machine vision software platforms also offer advanced calibration modules, allowing integration with different brands and hardware setups. Emerging technologies like AI-enhanced calibration can analyze environmental changes and auto-adjust camera parameters in real time, further improving precision.

Integrating Calibration into Production Workflows

In modern factories, calibration is not a one-time event but an integrated part of the production workflow. For example, an automotive assembly line might schedule automatic calibration routines during planned production pauses. In electronics manufacturing, in-line calibration stations can verify and adjust camera accuracy between batches. By embedding calibration into workflow automation, companies minimize downtime while ensuring consistent quality control.

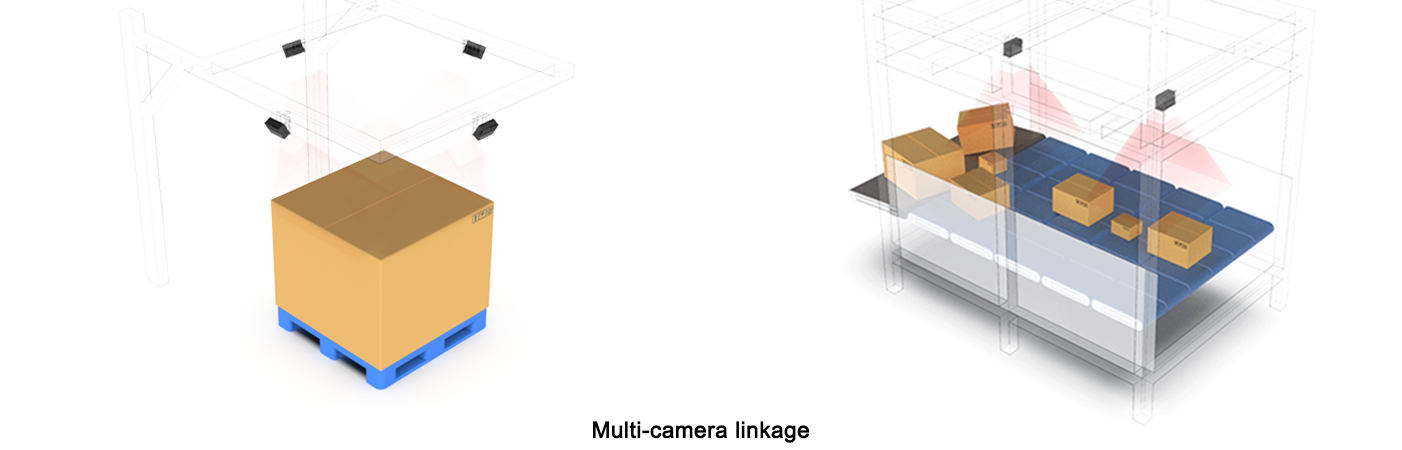

Calibration for Multi-Camera Systems

Many industrial applications use multiple 3D cameras to capture different angles or to cover large working areas. In such cases, multi-camera calibration is necessary to ensure that all cameras share the same coordinate system. This process, known as extrinsic calibration between cameras, aligns the data so that a single unified 3D model can be created without mismatches or overlaps. This is critical in applications such as large-scale 3D scanning, robotic bin picking, and automated warehouse navigation.

Maintenance and Recalibration Best Practices

For maximum performance, industrial 3D cameras should be recalibrated at regular intervals. The frequency depends on usage, environmental stability, and system mobility. High-vibration or high-temperature environments may require weekly recalibration, while stable, controlled environments might only need it quarterly. Documenting calibration dates, methods, and results helps maintain traceability and ensures compliance with industry standards, especially in regulated sectors like aerospace, medical device manufacturing, and automotive production.

The Cost of Neglecting Calibration

Neglecting calibration can have serious consequences. Inaccurate measurements may lead to defective products, costly recalls, or even safety hazards. For instance, in aerospace manufacturing, an incorrectly calibrated 3D vision system could produce flawed components, compromising structural integrity. The cost of downtime to recalibrate is minimal compared to the losses from quality failures. Companies that prioritize calibration not only safeguard product quality but also protect their reputation and bottom line.

Conclusion

Industrial 3D camera calibration is the foundation of accurate machine vision. Whether in robotic assembly, precision inspection, or large-scale scanning, the quality of your data depends on how well your cameras are calibrated. By understanding the process, addressing environmental challenges, and integrating calibration into your workflows, you can achieve consistent, high-precision results. As technology advances, automated and AI-driven calibration will further streamline this process, making it easier for industries to maintain peak performance without sacrificing uptime.