2D, 2.5D and 3D Technologies in Machine Vision

Machine vision technology is an important pillar of modern industrial automation and smart manufacturing, widely used in inspection, navigation, quality control and other fields. Among them, 2D, 2.5D and 3D vision technologies are three core technologies, each with different characteristics and applicable scenarios.

I. 2D Vision Technology: Viewing Plane, Simple and Efficient

1. Technical Characteristics

2D vision technology processes plane images, similar to taking a photo with a camera and completing tasks by analyzing this photo. Its main steps include:

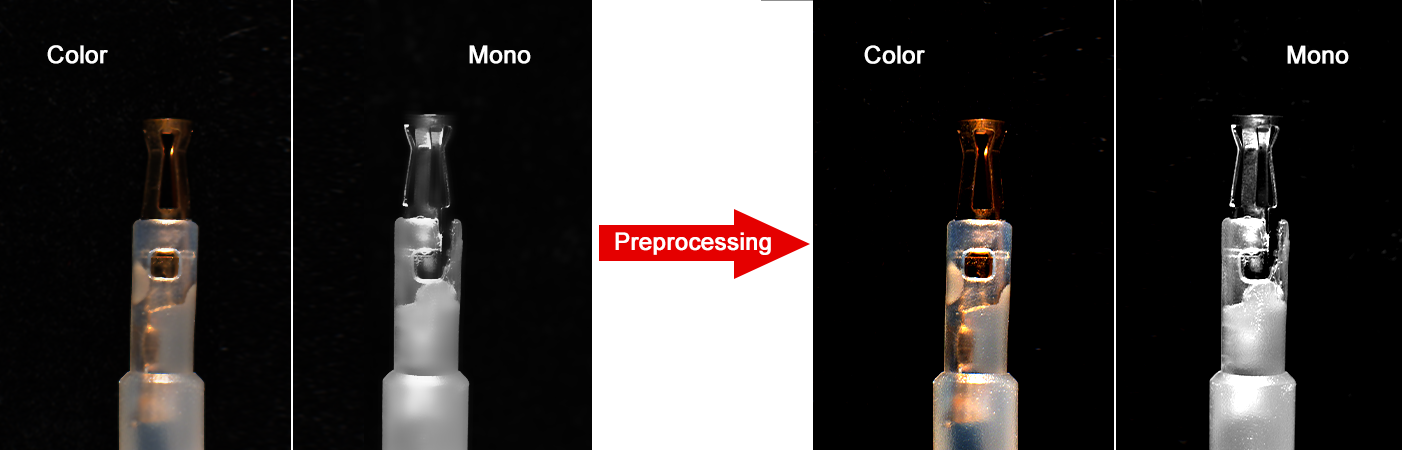

Image acquisition: Use industrial cameras to capture grayscale or color images, with lighting to make photos clearer.

Preprocessing: Make key information in images more prominent through filtering or contrast enhancement.

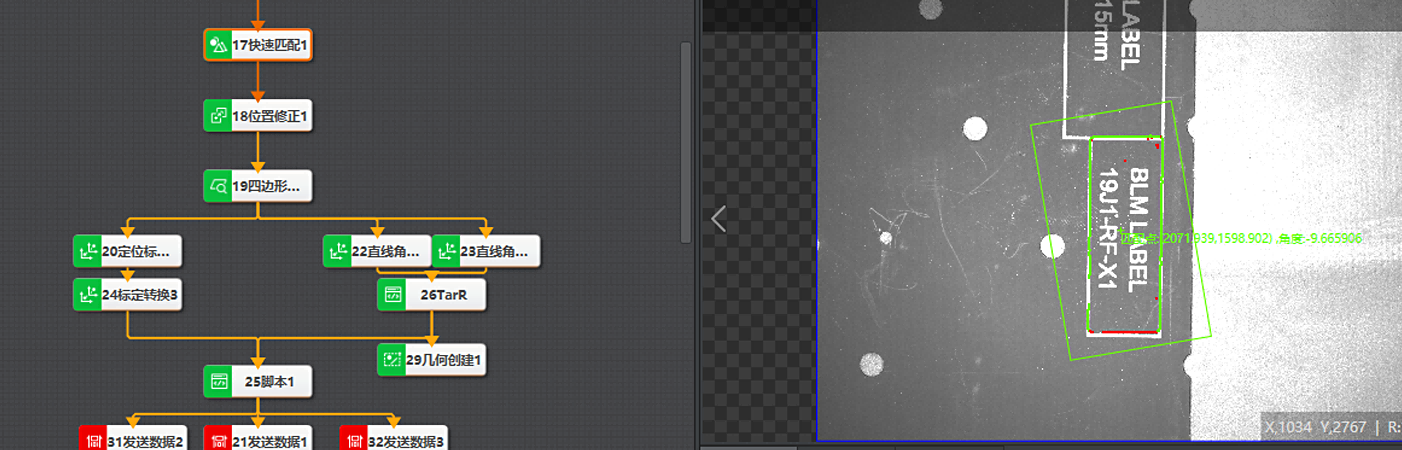

Feature extraction: Identify features like straight lines, contours or corner points in photos.

Pattern recognition: Use algorithms to judge what these features are, such as text or patterns.

Measurement and positioning: Calculate object size and position.

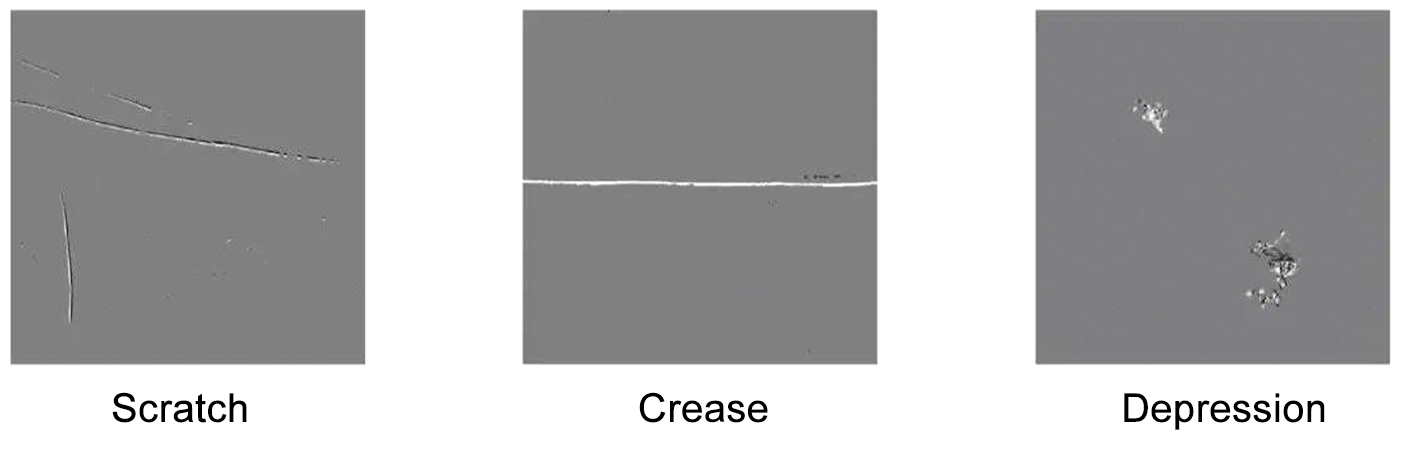

Defect detection: Compare with standard images to find where problems exist.

2. Applicable Scenarios

2D vision technology is suitable for tasks that only need to see surfaces and don’t require object thickness, such as:

Checking if product labels are printed correctly in factories.

Scanning barcodes on logistics packages.

Detecting scratches or stains on circuit board surfaces.

3. Advantages and Limitations

Advantages: Simple equipment, low cost, fast processing speed, suitable for quickly completing large-volume tasks.

Limitations: Cannot know object height or depth, powerless against complex shapes or occluded objects.

II. 2.5D Vision Technology: Adding Height, Half-Step Stereo

1. Technical Characteristics

2.5D vision technology adds one more layer of information to 2D: object height. It is not a complete 3D model but uses lasers or depth cameras to mark height at each point on plane images. Common methods include:

Contour measurement: Scan object surface with laser to measure height changes.

Depth map: Use special cameras to generate images with height information.

Simply put, 2.5D is like adding a "height tag" to plane photos but can only view from one angle.

2. Applicable Scenarios

2.5D is suitable for scenarios needing object height but not full 3D shape, such as:

Checking if component heights on circuit boards are normal.

Measuring whether object surfaces are flat or have bumps.

Helping robots judge obstacle height during navigation.

3. Advantages and Limitations

Advantages: Has more height information than 2D but cheaper and simpler than 3D; good cost-performance.

Limitations: Can only view from one angle; cannot handle complex 3D structures or multi-surface occlusion.

III. 3D Vision Technology: Full Stereo, Information-Rich

1. Technical Characteristics

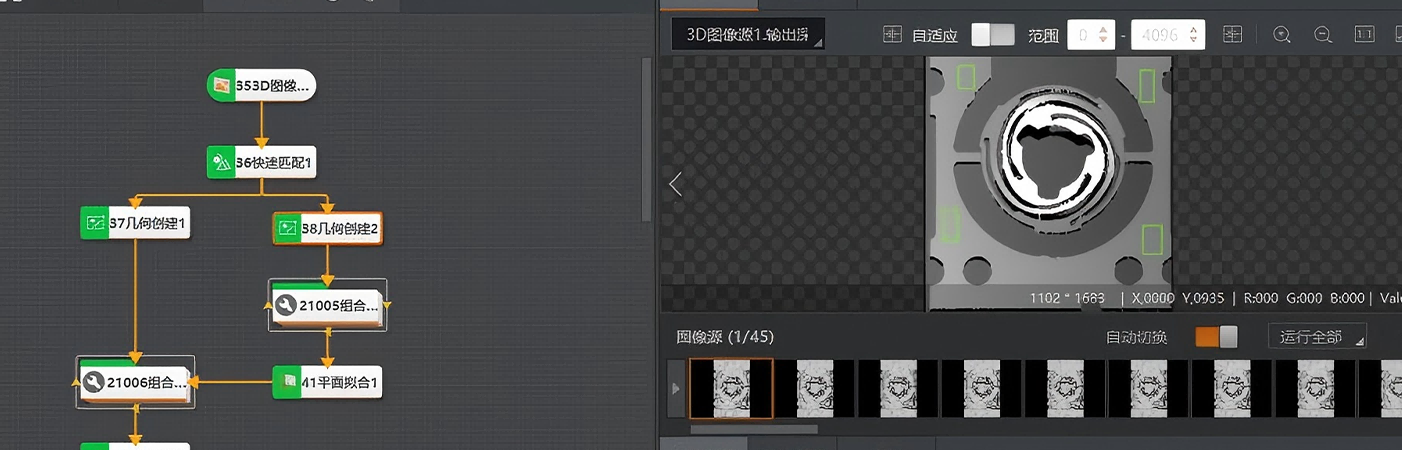

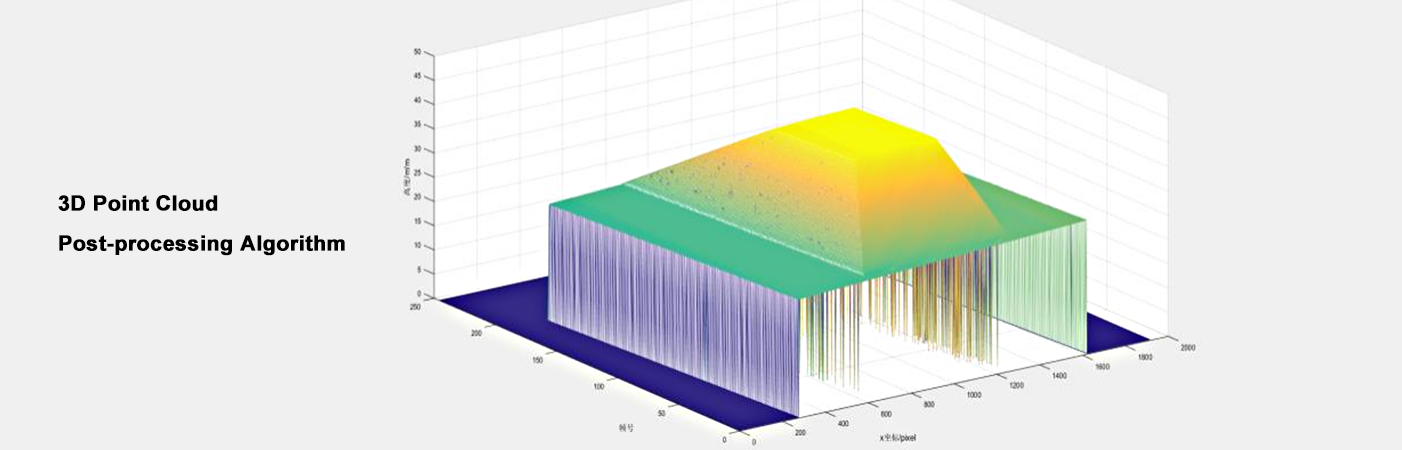

3D vision technology can fully present an object’s 3D shape and spatial position, like drawing a panoramic picture of the object. Implementation methods include:

Stereo vision: Use multiple cameras to take photos from different angles and calculate depth.

Laser scanning: Scan object surface with laser to record shape.

Structured light: Project light patterns onto objects and reconstruct 3D shape based on deformation.

Time of Flight (ToF): Measure light’s emission-return time to calculate distance.

3D reconstruction: Use multiple photos or point cloud data to assemble 3D models.

2.Applicable Scenarios

3D technology is suitable for tasks requiring precise 3D information, such as:

Guiding robots to grasp irregular objects.

Checking if complex parts are assembled correctly.

Measuring package volume in logistics to optimize space.

Building stereo maps of surroundings in autonomous driving.

3.Advantages and Limitations

Advantages: Provides complete spatial information; handles complex scenarios and high-precision needs.

Limitations: Complex equipment, high cost, slow processing speed, requires more computing resources.

IV. Comparison of 2D, 2.5D and 3D: Clear at a Glance

1. Technical Feature Comparison

|

Aspect |

2D Vision |

2.5D Vision |

3D Vision |

|

Data type |

Plane image |

Plane image + height |

Complete 3D model |

|

Depth information |

None |

Single-angle depth |

Multi-angle depth |

|

Equipment complexity |

Simple |

Medium |

Complex |

|

Cost |

Low |

Medium |

High |

|

Processing speed |

Fast |

Medium |

Slow |

2. Problems Solved

2D vision: Excels at plane tasks, e.g., reading barcodes, checking colors/text.

2.5D vision: Solves simple height-related problems, e.g., surface defects or component height inspection.

3D vision: Suitable for complex 3D tasks, e.g., locating irregular objects or analyzing spatial relationships.

3. Practical Application Examples

(1) Automotive manufacturing:

2D: Inspect car body paint and part markings

2.5D: Measure car body surface flatness

3D: Guide robot welding or part handling

(2) Electronics industry:

2D: Inspect circuit board surface soldering

2.5D: Detect component heights

3D: Verify complex component assembly

(3) Logistics:

2D: Scan package labels

2.5D: Measure package height

3D: Calculate package volume, optimize storage

V. Technology Trends: Convergence and Development

Current machine vision technology develops rapidly. 2D, 2.5D and 3D are moving closer:

Popularization of 2.5D: Depth cameras becoming cheaper, practical choice for many tasks.

AI empowerment: Using AI to analyze images and 3D data for more precise results.

Technology fusion: Some systems flexibly switch among three technologies based on tasks to improve efficiency.

VI. Conclusion: Choosing the Right Technology is Key

2D, 2.5D and 3D vision technologies each have strengths:

2D: Simple and fast, suitable for surface tasks

2.5D: Adds height information, suitable for medium demands

3D: Powerful functionality, suitable for complex 3D tasks