AI-Powered Inspection: Revolutionizing Quality Control with Precision

The New Era of Quality Control

Imagine a factory where every product is flawless, defects are caught in milliseconds, and human error is a thing of the past. Sounds like a dream? Thanks to artificial intelligence (AI), this is now reality. AI-powered inspection systems are transforming how industries ensure quality, delivering unmatched precision and efficiency. From spotting tiny cracks in electronics to ensuring perfect packaging in food production, AI is redefining what’s possible in quality control. In this blog post, we’ll explore how AI automates the inspection process, identifies defects with pinpoint accuracy, and why it’s a game-changer for businesses aiming to stay competitive.

Why AI in Inspection Matters

Quality control is the backbone of manufacturing, but traditional methods—relying on human inspectors or basic automation—often fall short. Humans get tired, miss subtle defects, or struggle with high-speed production lines. Basic automated systems, while faster, lack the nuance to handle complex or variable defects. Enter AI, which combines the speed of machines with near-human intuition, powered by advanced algorithms and machine vision.

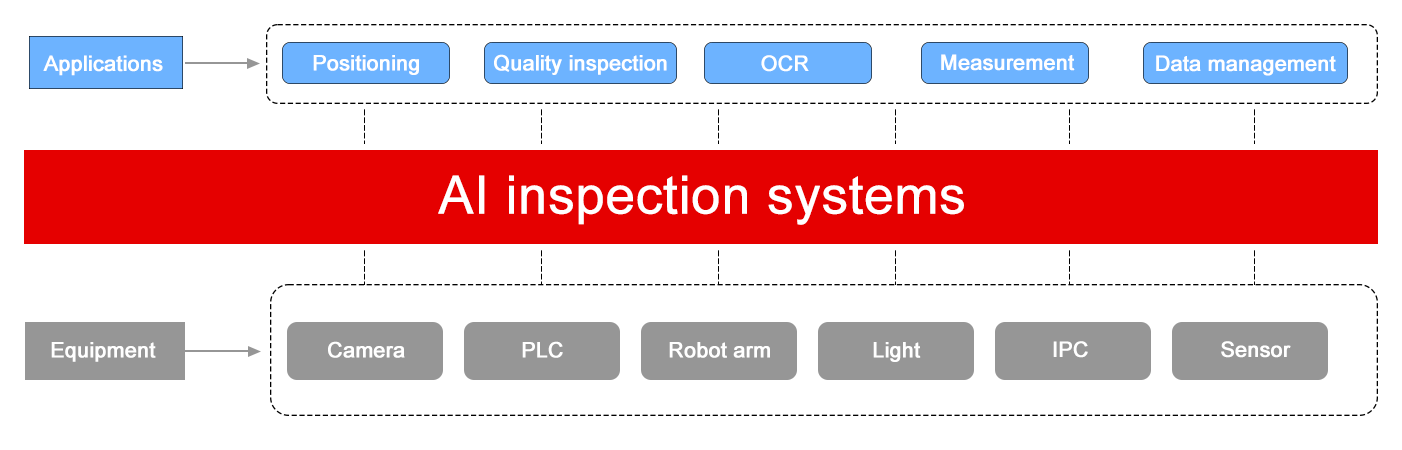

AI inspection systems use cameras, sensors, and deep learning to analyze products in real-time. They “learn” what a perfect product looks like and instantly flag anything that deviates—whether it’s a scratch on a phone screen or an uneven seal on a medicine bottle. The result? Higher accuracy, lower costs, and fewer defective products reaching customers.

Key Benefits of AI-Powered Inspection

Precision: Detects defects as small as a fraction of a millimeter.

Speed: Processes thousands of items per minute, keeping up with modern production lines.

Consistency: Never tires, ensuring 24/7 reliability.

Cost Savings: Reduces waste, rework, and customer complaints.

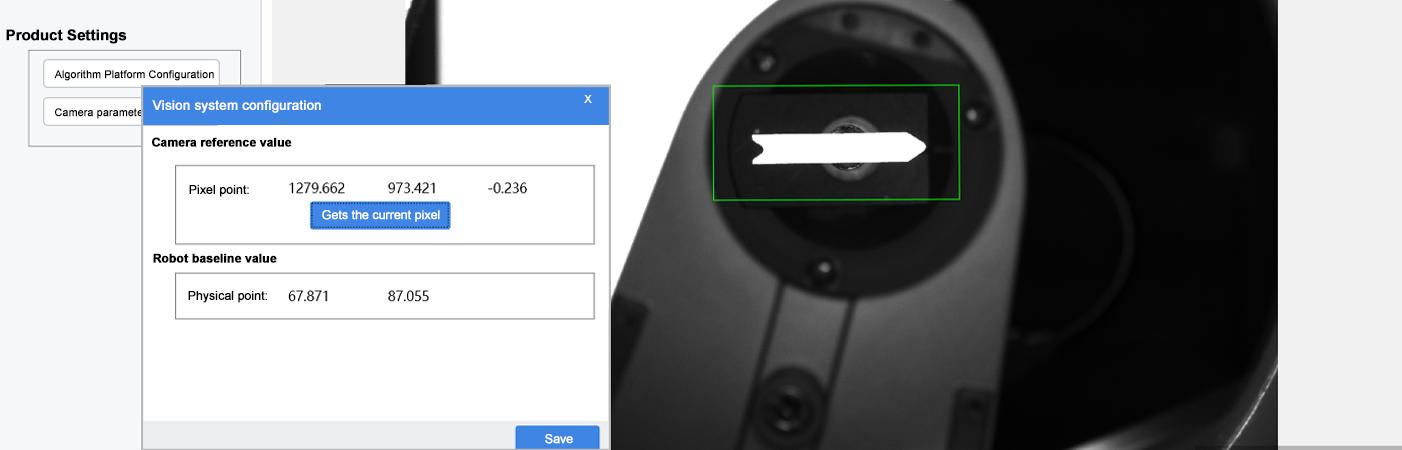

How AI Automates the Inspection Process

AI inspection systems are built on machine vision and deep learning, working together like a super-smart quality control expert. Here’s how it works in three simple steps:

Image Capture: High-resolution cameras or sensors scan products as they move through the production line. For example, a camera might snap images of a circuit board from multiple angles.

Analysis: AI algorithms, trained on thousands of “good” and “defective” product images, analyze the scans in real-time. They can spot inconsistencies—like a misaligned component or a surface blemish—faster than any human.

Action: If a defect is detected, the system flags it instantly. It might trigger an alert, divert the faulty item, or even adjust the production process to prevent future issues.

For instance, in automotive manufacturing, AI can inspect welds on car frames, catching imperfections that could compromise safety. In food production, it ensures labels are correctly applied, preventing costly recalls.

Real-World Applications of AI Inspection

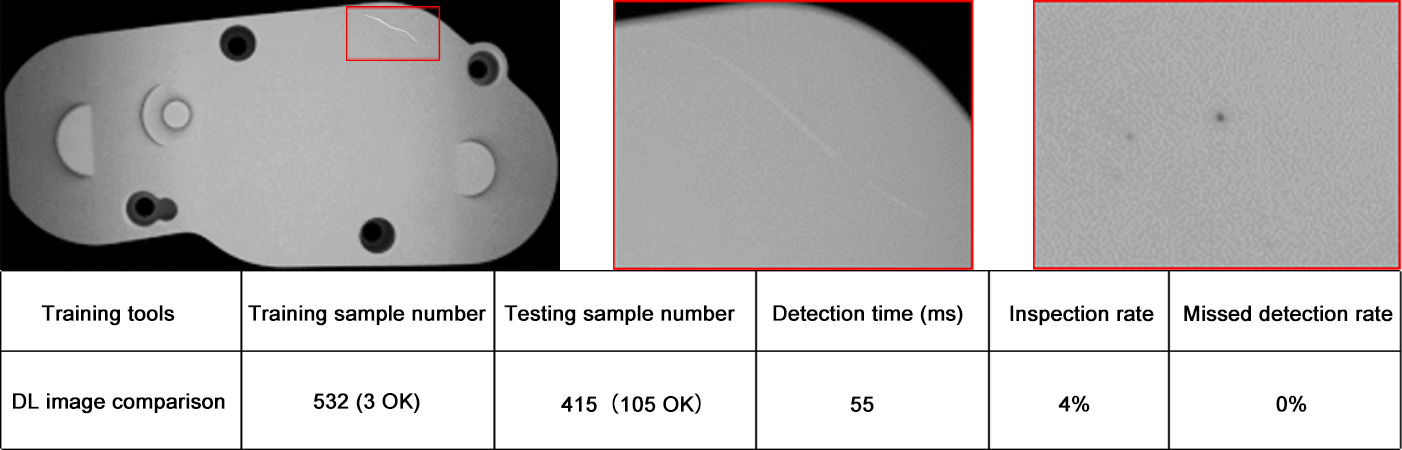

AI’s ability to identify defects with high precision is transforming industries. Here are a few examples:

Electronics: AI detects micro-cracks or soldering errors in circuit boards, ensuring devices work flawlessly.

Pharmaceuticals: It verifies pill shapes, colors, or packaging integrity, critical for patient safety.

Automotive: AI inspects engine parts or paint finishes, reducing defects in high-stakes components.

Food and Beverage: It checks for contamination, improper seals, or mislabeled products, protecting consumers and brands.

One real-world case: a major electronics manufacturer implemented AI inspection and reduced defect rates by 30%, saving millions annually in rework costs. Another, in food packaging, cut recall incidents by 25% with AI-driven label checks.

Challenges and Solutions

While AI inspection is powerful, it’s not without hurdles. Training AI models requires large datasets of defect images, which can be time-consuming to gather. Additionally, integrating AI into existing production lines may demand upfront investment. However, solutions are emerging:

Pre-Trained Models: Many AI platforms now offer models pre-trained on common defects, reducing setup time.

Cloud-Based AI: Affordable cloud solutions lower costs, making AI accessible to smaller businesses.

Hybrid Systems: Combining AI with human oversight ensures accuracy while systems learn.

Why Now Is the Time to Adopt AI Inspection

The global market for AI in manufacturing is projected to grow rapidly, with quality control leading the charge. Businesses that adopt AI inspection now gain a competitive edge—delivering better products, reducing waste, and building customer trust. As consumer expectations rise and regulations tighten, relying on outdated methods risks falling behind.

Plus, AI isn’t just about catching defects; it’s about learning from them. Over time, AI systems analyze patterns to predict and prevent issues, making production smarter and more efficient.

Call to Action: Transform Your Quality Control Today

Ready to take your quality control to the next level? AI-powered inspection isn’t just for tech giants—it’s accessible to businesses of all sizes. Start by exploring AI solutions tailored to your industry, whether it’s electronics, automotive, or food production. contact a machine vision expert to see a demo in action. Don’t let defects slow you down—embrace AI and deliver perfection every time.