How to Choose the Right Industrial Camera - A Comprehensive Guide

Choosing the right industrial camera feels like a mission impossible.

There are so many specs: resolution, frame rate, sensor type, shutter... it’s easy to get lost.

Most people make a critical mistake: they focus on the camera first, instead of the application.

This is backward.

Your camera is only one part of a complete vision system. A high-end camera with the wrong lens or poor lighting is useless.

Here’s a simple guide to choosing the right industrial camera, step-by-step, by starting with what actually matters: your specific needs.

1. Define Your Application. What Are You Actually Trying to Do?

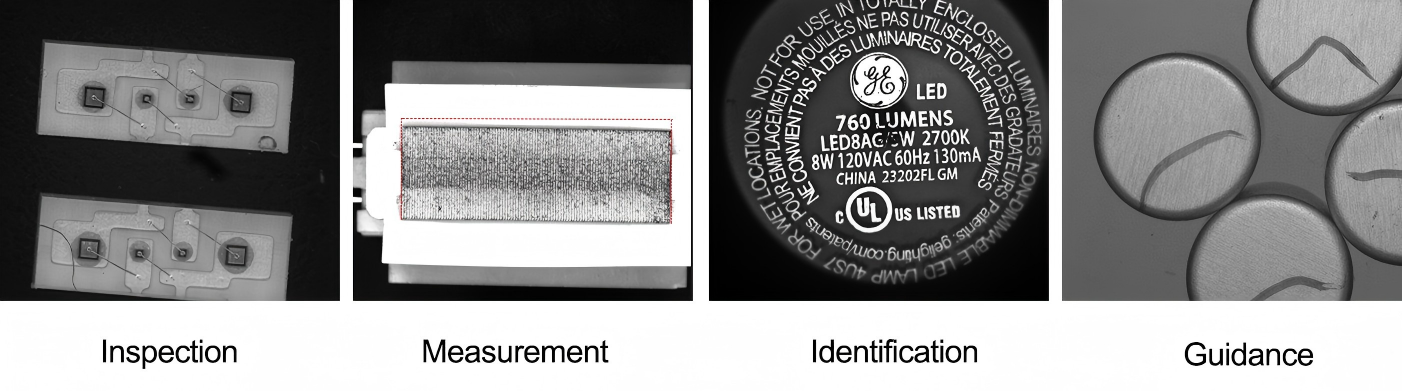

Inspection: Are you checking for defects, scratches, or alignment issues?

Measurement: Are you measuring dimensions with high precision?

Identification: Is it for reading barcodes, QR codes, or text (OCR)?

Guidance: Is the camera guiding a robot for "pick and place" tasks?

Your goal dictates everything that follows.

2. The Four Pillars of Camera Selection

Once you know your goal, these four factors will narrow down your choices fast:

Resolution: Don't just go for the highest megapixels. Calculate the pixel resolution needed. A common rule for traditional machine vision is that the smallest feature you need to detect should span at least 3-5 pixels. For AI-based systems, it's often more.

Frame Rate: How fast is your object moving? If you're inspecting items on a high-speed conveyor belt, you need a high frame rate (frames per second, or FPS) to prevent motion blur and ensure every item is captured.

Sensor Type & Shutter:

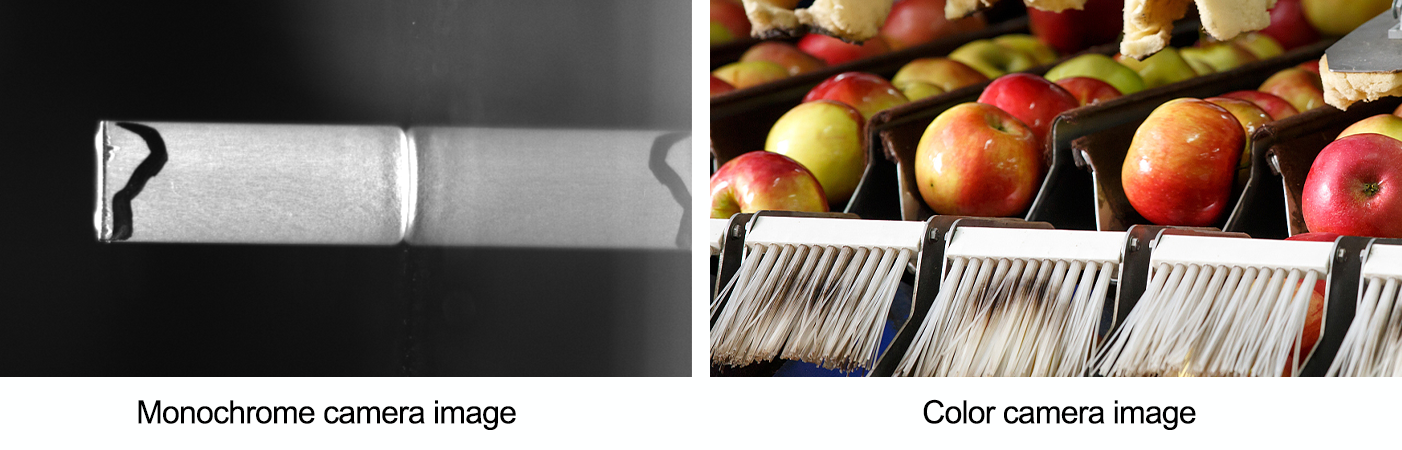

Monochrome vs. Color: If you're only concerned with shapes and details (like OCR or defect detection), a monochrome camera is often better. It’s more sensitive to light and provides a sharper image. Use color only when the color itself is a critical part of the inspection (e.g., sorting colored pills or fruits).

Global vs. Rolling Shutter: This is critical for moving objects. A global shutter captures the entire image at once, eliminating distortion on fast-moving parts. A rolling shutter scans the image line by line, which can cause a "jello" effect on moving objects—a dealbreaker for many industrial applications.

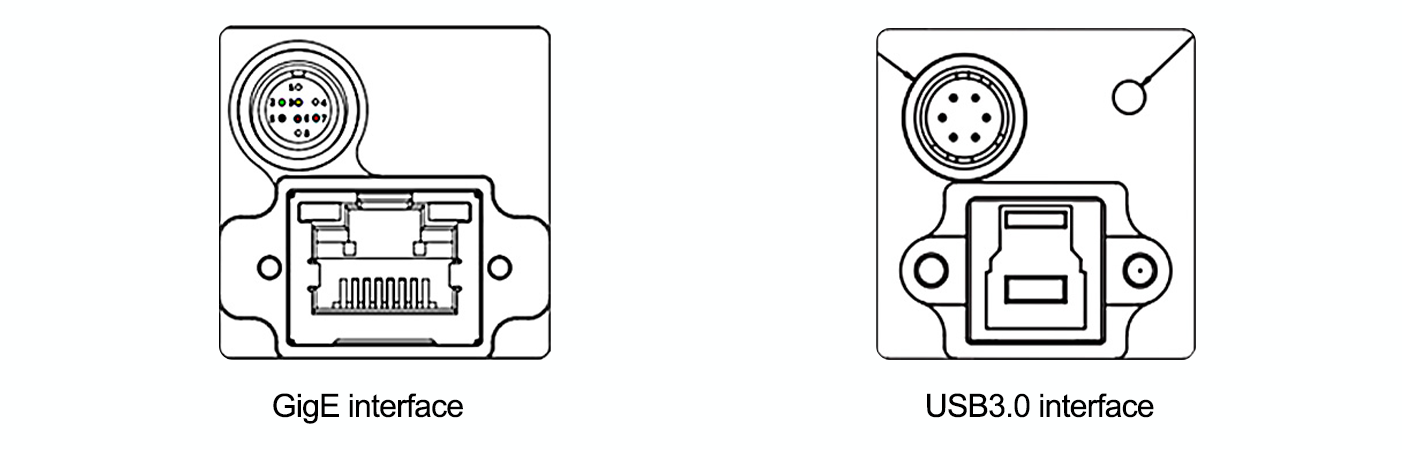

Interface: This determines how the camera connects to your computer and system. Common options are GigE Vision (for long-distance, high-bandwidth needs) and USB3 Vision (fast and simple for shorter distances). The right interface depends on your system architecture.

3. Don't Forget the Environment

Your camera needs to survive its workplace. Consider:

Lighting: Is the environment well-lit, or do you need a camera with high light sensitivity (large pixels)? Can you control the lighting with strobes or specific illuminators?

Durability: Does the camera need an IP rating (like IP67) to be dust-tight or resistant to water jets?

Temperature: Does it need to operate in extreme heat or cold?

Final Checklist Before You Buy

Define the task: What do you need to see?

Calculate: The required resolution and frame rate.

Match: Sensor, shutter, and interface to your application.

Check: The environmental requirements.

Consult: Talk to a machine vision expert or a supplier's application engineer.

By following this process, you’ll stop guessing and start building a reliable, high-performing vision system that works every time.

Want to dive deeper into machine vision solutions for your specific industry?

Please send HIFLY an email right now.