Industrial 3D Camera: Key Features and Benefits

Introduction to Industrial 3D Cameras

In the rapidly advancing world of automation, robotics, and quality control, industrial 3D cameras have emerged as a transformative technology. Unlike traditional 2D cameras that capture flat images, 3D cameras record depth information, enabling machines to perceive the world more like human eyes do. This added dimension is crucial for applications that require accurate measurements, object recognition, and spatial analysis. From manufacturing to logistics, industrial 3D cameras are helping businesses achieve higher precision, faster processing, and greater flexibility.

How Industrial 3D Cameras Work

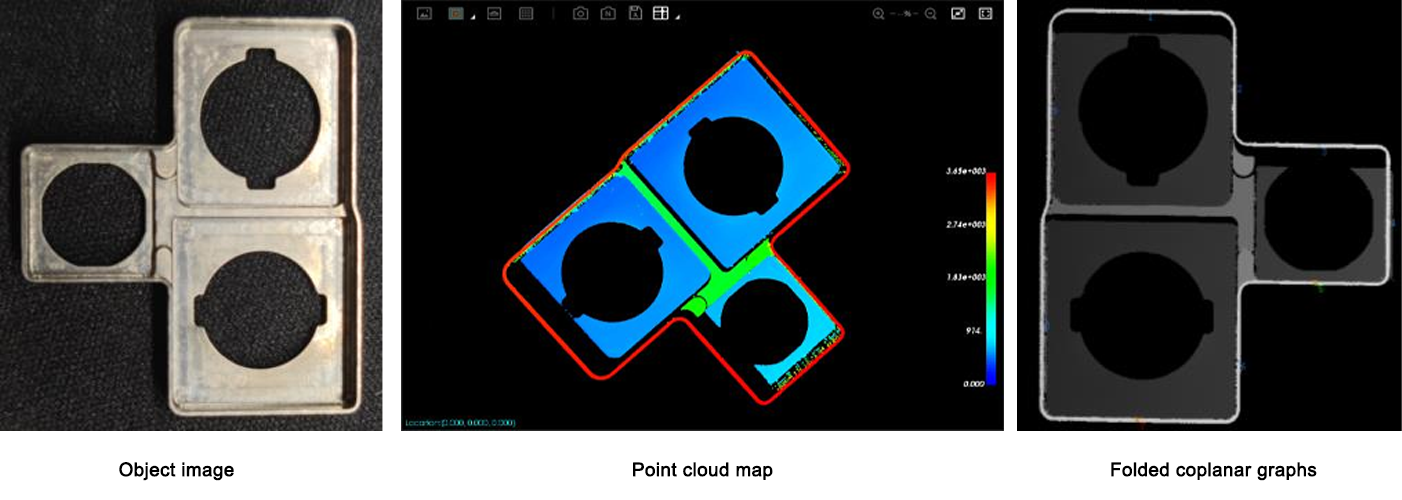

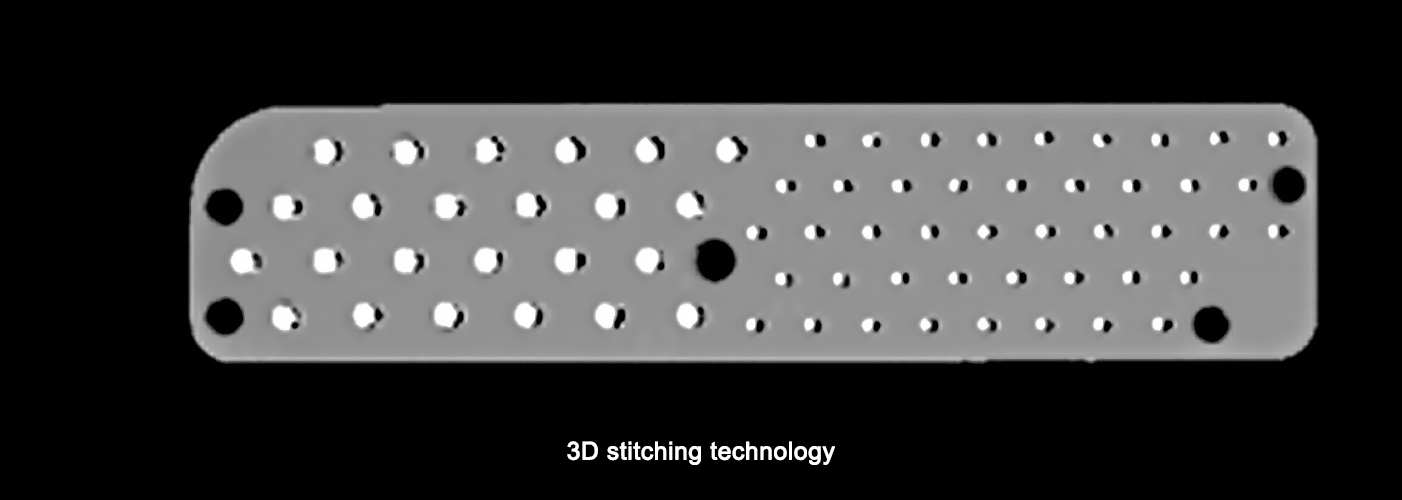

Industrial 3D cameras use various technologies—such as structured light, time-of-flight (ToF), laser triangulation, or stereo vision—to capture depth data. The camera projects or detects patterns of light and then calculates the distance to each point in the scene. This data forms a point cloud, which is essentially a digital 3D map of the object or environment. Advanced software can then process the point cloud to identify shapes, measure dimensions, detect defects, or guide robotic arms.

Key Features of Industrial 3D Cameras

High Depth Accuracy

One of the defining features of industrial 3D cameras is their ability to measure depth with sub-millimeter accuracy. This capability is vital in quality inspection, where even the smallest deviations can signal defects.

Wide Field of View

Depending on the model, these cameras can capture a wide area in a single frame, reducing the need for multiple units. This feature is particularly beneficial in logistics, where scanning large parcels or pallets quickly is essential.

Robust Build Quality

Industrial environments can be harsh, with dust, vibrations, and temperature fluctuations. High-quality 3D cameras are built with rugged housings, sealed to IP standards, and engineered to withstand these conditions without performance loss.

High-Speed Capture

In production lines where objects move rapidly, cameras must process images quickly to keep up. Industrial 3D cameras often feature high frame rates, enabling real-time inspection and decision-making without slowing operations.

Flexible Mounting and Integration

Most industrial 3D cameras are designed for easy integration into existing systems. They offer multiple mounting options and are compatible with various industrial protocols like GigE Vision or USB3 Vision.

Benefits of Using Industrial 3D Cameras

Enhanced Quality Control

By capturing precise 3D data, manufacturers can detect defects that 2D systems might miss—such as subtle warping, surface irregularities, or incomplete assemblies. This leads to fewer defective products reaching customers.

Increased Automation Efficiency

In robotics, 3D cameras enable accurate object localization and orientation, making it possible for robots to pick and place parts with minimal errors. This reduces manual intervention and increases throughput.

Reduced Waste and Costs

Accurate inspection means fewer false rejects and rework, leading to significant cost savings over time. By catching defects early, businesses also reduce material waste.

Versatility Across Applications

Whether in electronics, automotive, food processing, or logistics, industrial 3D cameras can be adapted for tasks like bin picking, dimensioning, surface profiling, and more.

Common Applications

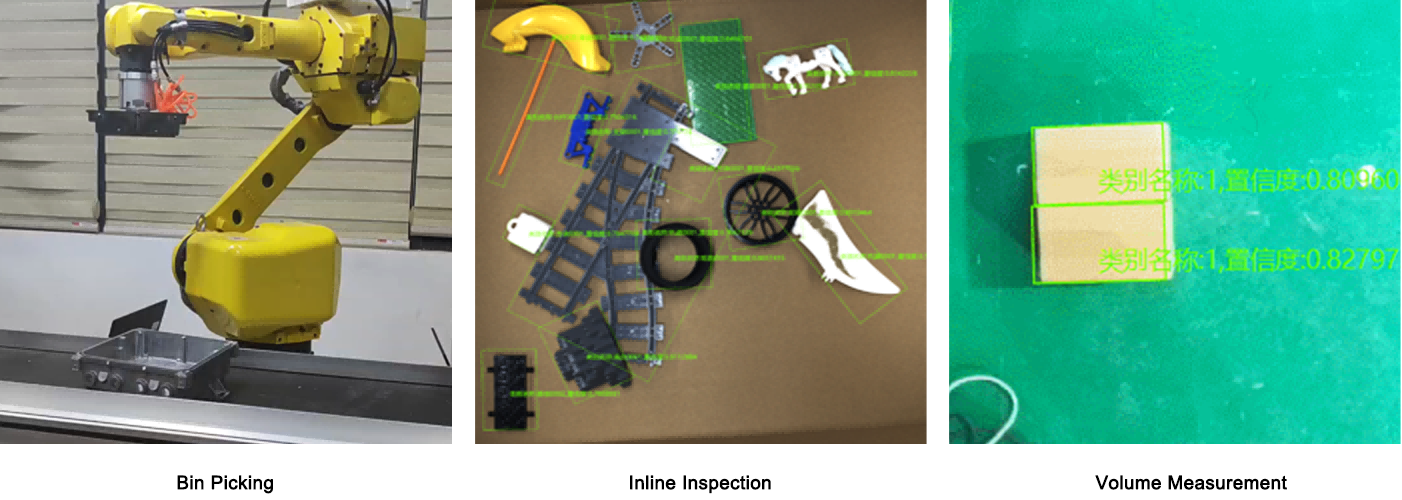

- Bin Picking: Robots equipped with 3D cameras can identify and retrieve items from bins with random orientations, a task impossible for traditional vision systems.

- Inline Inspection: Continuous quality checks ensure each product meets specifications without interrupting the production flow.

- Volume Measurement: In logistics, 3D cameras can automatically measure package dimensions for sorting and shipping optimization.

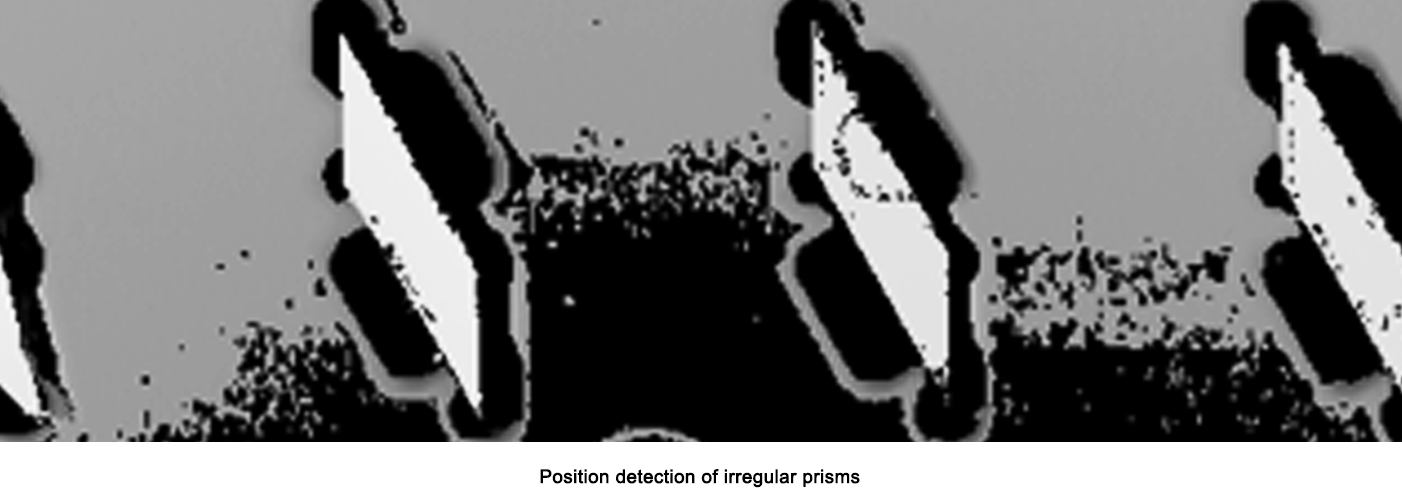

- Surface Defect Detection: Detecting dents, bumps, or scratches on manufactured goods in real time.

Choosing the Right Industrial 3D Camera

When selecting a 3D camera for industrial use, consider:

- Resolution and Accuracy: Higher resolution allows for finer detail capture, but may require more processing power.

- Working Distance: The optimal range between the camera and the object must match your application’s requirements.

- Lighting Conditions: Some cameras are better suited for low-light or high-glare environments.

- Integration Capabilities: Ensure the camera is compatible with your existing software, controllers, and workflow.

Case Study: Improving Assembly Line Accuracy

A precision electronics manufacturer implemented an industrial 3D camera system for component placement verification. Before integration, occasional misalignments led to costly rework. After deploying 3D cameras with high-speed depth analysis, the defect rate dropped by 40%, and production throughput increased by 20%. This improvement paid for the system within a year, illustrating the tangible ROI of 3D imaging technology.

Future Trends in Industrial 3D Cameras

As AI and machine learning continue to evolve, their integration with 3D vision systems will unlock even greater potential. We can expect smarter defect detection, faster processing speeds, and cameras that self-optimize for different products or environmental conditions. Additionally, miniaturization and cost reduction will make these technologies more accessible to small and medium-sized enterprises.

Conclusion

The industrial 3D camera is more than just a tool for capturing images—it’s a gateway to smarter, faster, and more accurate industrial processes. By offering unparalleled depth perception, high precision, and adaptability, these cameras are transforming quality control, automation, and logistics across industries. As technology advances, their role in driving efficiency and innovation will only grow, making them a must-have for businesses aiming to remain competitive in a rapidly changing industrial landscape.