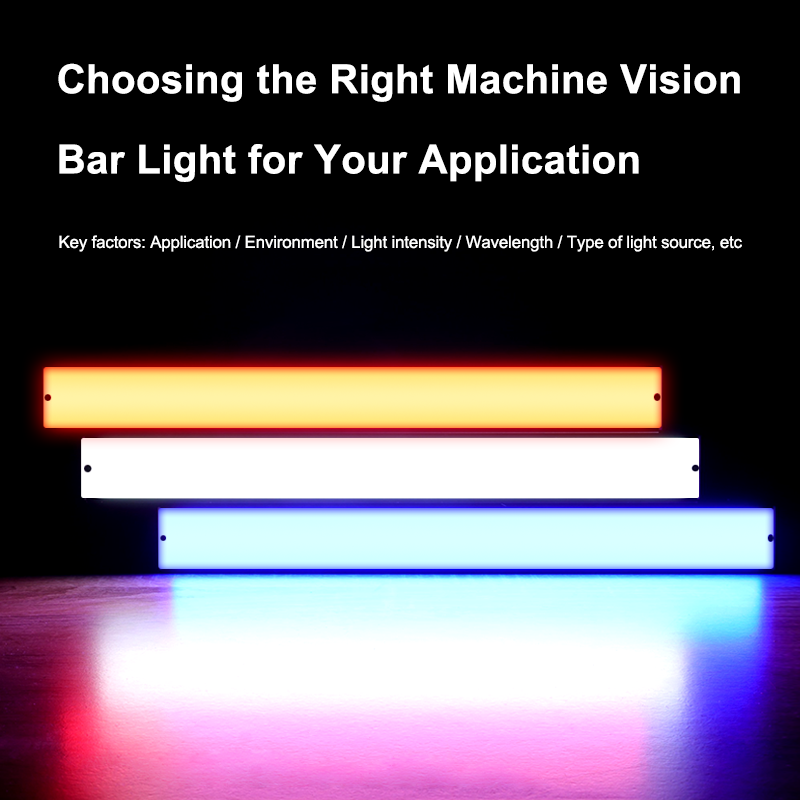

Choosing the Right Machine Vision Bar Light for Your Application

As the world of industrial automation and machine vision rapidly evolves, the correct lighting solution holds paramount importance for ensuring accurate image capture, clear inspections, and optimized performance. One of the most versatile and widely used lighting options in machine vision systems is the machine vision bar light. Choosing the appropriate bar light for your specific application can significantly affect the quality of your system's output, whether it's for inspection, measurement, or quality control purposes. This article will guide you through the process of selecting the right machine vision bar light, considering various factors such as the application, environment, and lighting requirements.

Understanding Machine Vision Bar Lights

Machine vision bar lights are linear lighting fixtures designed specifically for use in machine vision applications. Unlike traditional lights, which may provide diffuse or omnidirectional light, bar lights focus their light output in a controlled and precise manner, often in a specific direction or pattern. This makes them ideal for illuminating specific areas in a machine vision system, such as a conveyor belt, a product surface, or a part under inspection.

The most common types of machine vision bar lights include:

Modular Bar Lights: Modular bar lights are customizable, linear LED illumination units designed so that multiple segments can be connected to create different lengths, shapes, or lighting configurations. This flexibility makes them ideal for adapting to various machine vision, inspection, or automation requirements.

High Intensity Bar Lights: These provide extremely bright, concentrated illumination for applications that demand maximum light output—such as high-speed inspections, long working distances, or environments with strong ambient light.

High Dispersion Narrow Bar Lights: These feature a slim, narrow housing combined with optics that spread light over a wide area. They are suited for applications needing even, broad coverage from a compact form factor, such as illuminating wide conveyor belts or large inspection surfaces.

Key Factors to Consider When Selecting

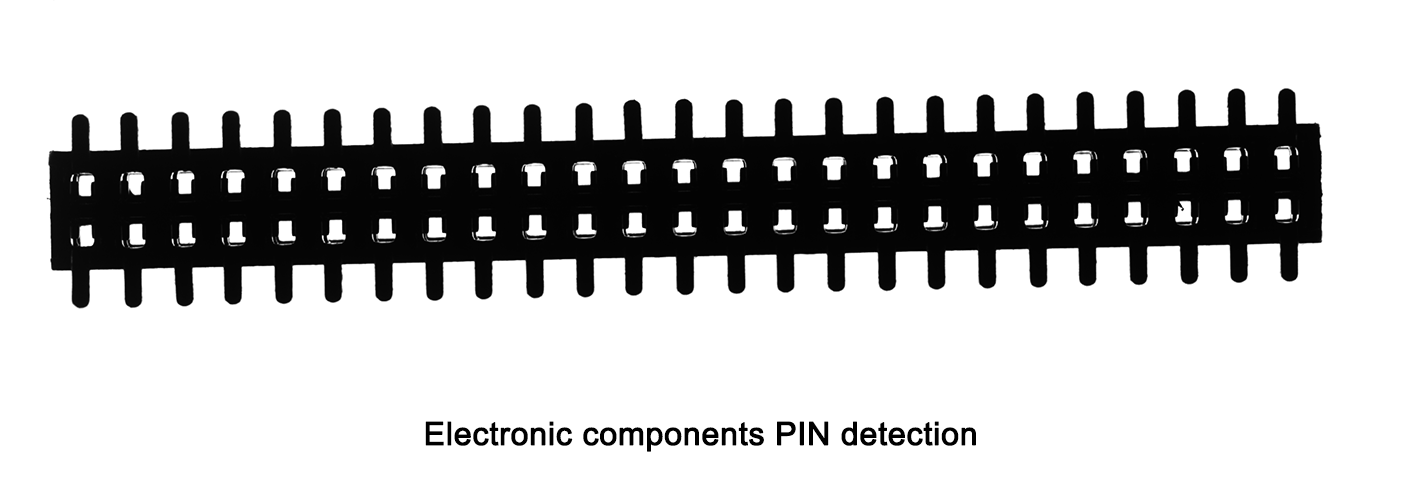

Selecting the right bar light for a machine vision system is critical to ensuring accurate inspection results and optimal performance. The first and most fundamental consideration is the object size and type. Knowing the dimensions, geometry, surface texture, and material properties of the object helps determine the appropriate length, shape, and intensity of the bar light. Objects with reflective or transparent surfaces may require diffuse or specialized wavelength lighting, whereas textured or matte surfaces may benefit from direct or structured illumination.

Illumination type and pattern are equally important. Front lights, backlights, diffuse lights, and ring lights each serve different purposes. Front lights highlight surface details, backlights create high-contrast silhouettes for edge detection, diffuse lights reduce shadows and glare, and ring lights provide uniform all-around illumination for curved or cylindrical objects. Choosing the correct illumination pattern ensures defects, edges, or markings are captured clearly.

Brightness and intensity control must match the camera’s exposure requirements and inspection speed. High-intensity bar lights are suitable for fast-moving objects or long working distances, while adjustable or strobe-controlled lights allow precise tuning for varying inspection conditions.

Wavelength selection is another critical factor. Different LED colors—red, blue, green, white, UV, IR, and SWIR—enhance contrast, reveal hidden features, or minimize unwanted reflections. Matching the wavelength to the material and defect type improves detection accuracy.

Why You will Need Machine Vision Bar Lights ?

1. Flexible Lighting Configuration

Multiple Illumination Modes – Supports both bright field and dark field setups to enhance desired features or suppress unwanted reflections.

Segment Control – Many LED bar lights feature individually addressable segments for running multiple inspection techniques in a single station.

Adjustable Positioning – Can be mounted at various angles and distances to suit different object shapes and sizes.

Quick Reconfiguration – Interchangeable windows and direct access to optics allow fast adjustments for production changes.

Line-Scan Compatibility – Can integrate with line-scan accessories for alternative geometries, including linear or dark-field illumination.

Multi-Technique Advantage – Offers greater adaptability than single-mode lighting options such as dome or diffuse lights.

2. Broad Application Coverage

- Versatile Usage – Suitable for conveyor line inspection, robotic guidance, pick-and-place operations, and logistics scan tunnels.

- High-Performance Illumination – Delivers uniform, edge-to-edge lighting for highlighting surface textures, detecting defects, and ensuring accurate measurements.

- Quality Control Support – Enhances inspection in packaging verification, component gauging, and process monitoring.

- Wavelength Variety – Available in red, blue, green, white, UV, IR, and SWIR to match material properties and improve contrast.

- Adjustable Intensity – Brightness control options for adapting to different inspection speeds and environments.

- Modular Design – Enables customization of length and configuration to fit diverse production requirements.

Conclusion

Choosing the right machine vision bar light is critical to optimizing your machine vision system’s performance. The key factors to consider include the specific requirements of your application, the environment in which the system will be operating, the light intensity and wavelength, and the type of light source. By carefully evaluating these factors and selecting a bar light that meets your needs, you can significantly improve the accuracy and efficiency of your machine vision system. Whether you’re inspecting parts, measuring components, or reading barcodes, the right lighting solution will ensure that your system captures the most accurate and high-quality images, leading to improved automation and productivity in your operations.