The Role of Machine Vision Backlight in Enhancing Image Quality

Understanding Machine Vision Backlighting

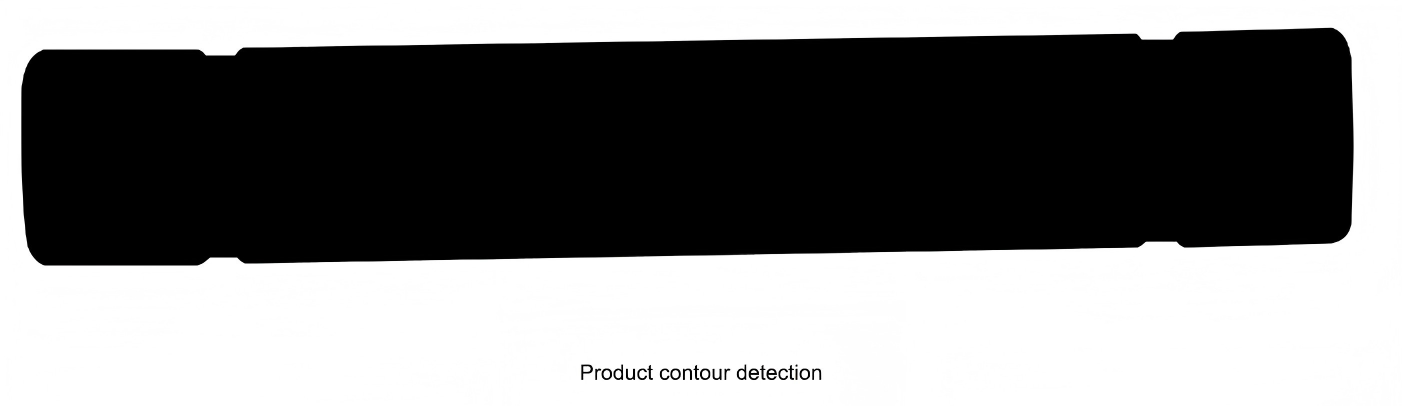

In industrial automation and quality inspection systems, machine vision backlighting plays a critical role in enabling precise image capture. Unlike front lighting or side lighting, backlighting positions the light source behind the object, creating a strong contrast between the object’s silhouette and the background. This approach is especially effective in applications where measuring edges, detecting shapes, or identifying small defects is essential. By illuminating from behind, machine vision systems can more accurately distinguish features, even in complex or high-speed environments.

Why Backlighting Improves Image Quality

Backlighting enhances image quality primarily by increasing the contrast between an object and its background. In many industrial imaging scenarios, surface reflections, shadows, and texture variations can complicate image analysis. Backlighting bypasses these issues by creating a consistent, bright background and rendering the object as a dark, sharply defined profile. This technique eliminates many of the inconsistencies that front lighting may introduce, enabling more reliable edge detection, dimensional measurement, and shape recognition.

Applications Across Industries

Machine vision backlights are used in diverse industries, from electronics manufacturing to packaging and pharmaceutical production. For example:

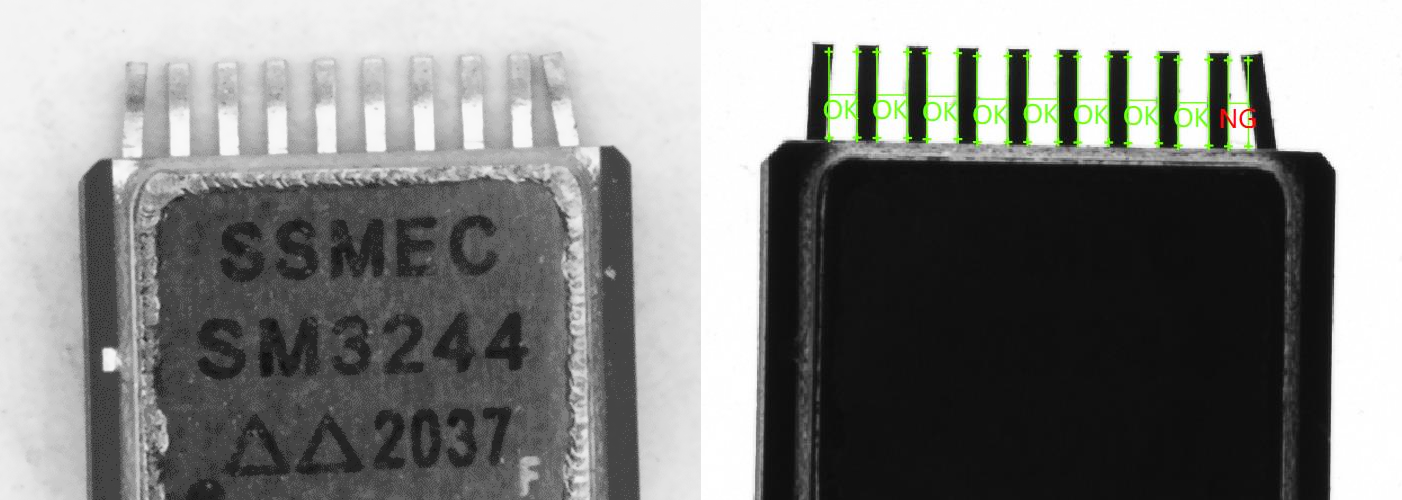

- Electronics inspection: Identifying defects in PCB components or connector pins.

- Packaging quality checks: Ensuring seals, labels, and shapes match exact specifications.

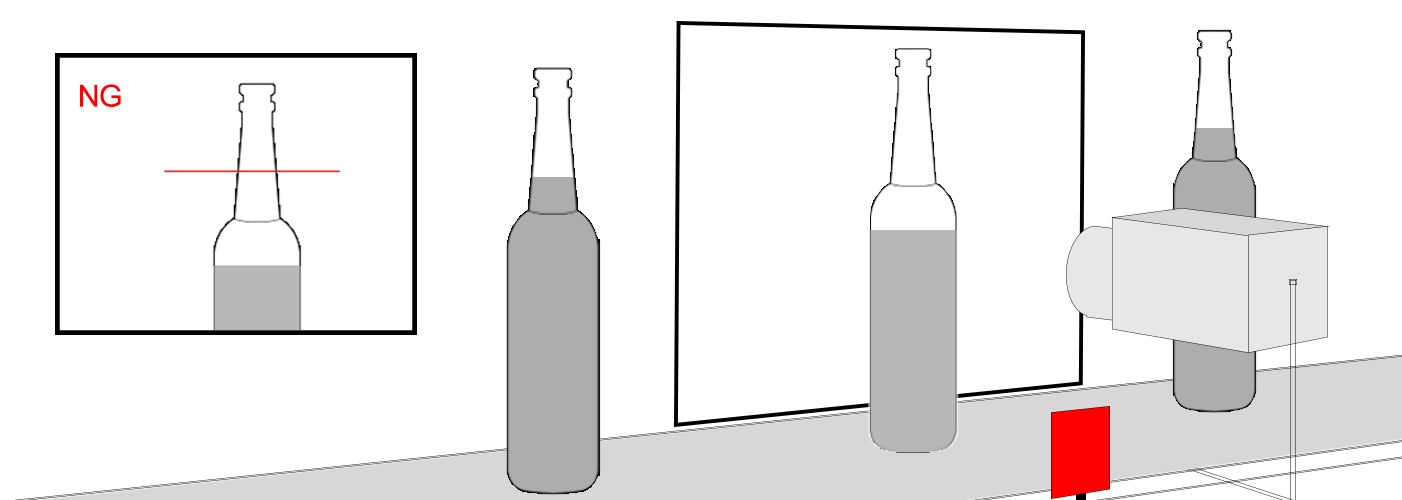

- Pharmaceuticals: Detecting tablet defects or fill levels in transparent containers.

- Automotive parts inspection: Measuring gaskets, gears, or precision-engineered components.

By providing a clear, high-contrast silhouette, backlighting allows machine vision algorithms to perform accurate measurements and detect anomalies with greater precision.

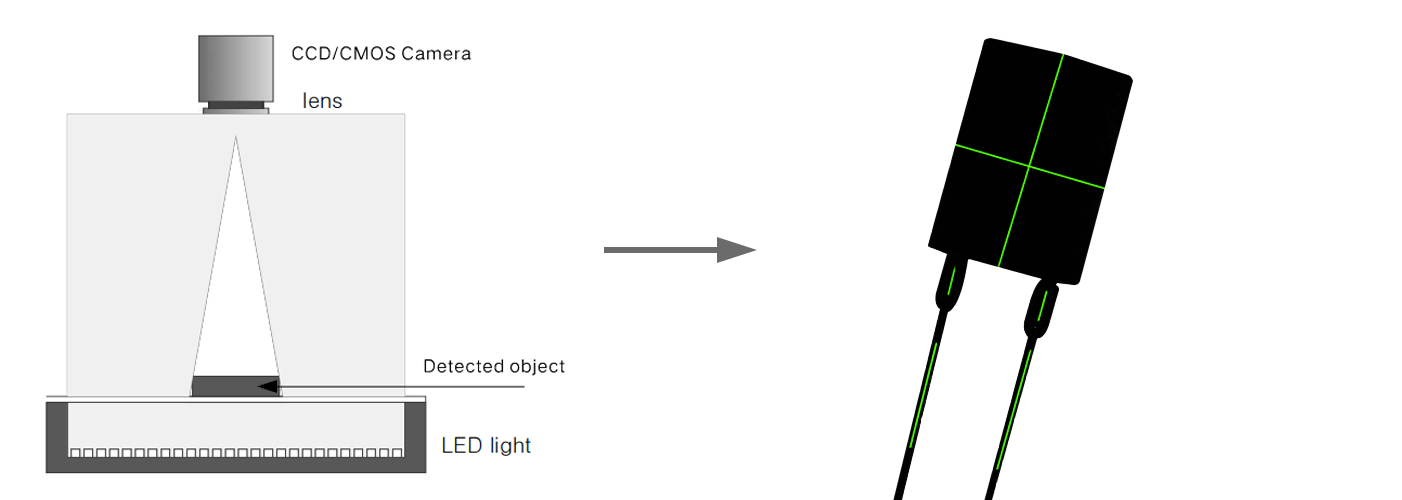

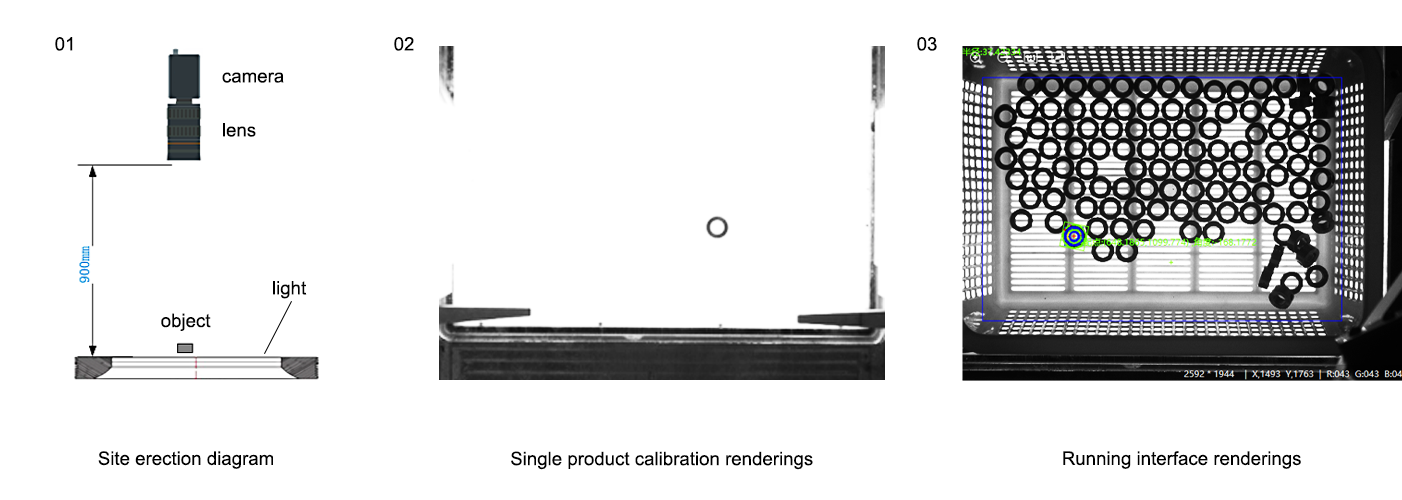

Integrating Backlighting into a Vision System

The effectiveness of a backlight depends not only on its quality but also on correct integration into the vision system. The light source must be positioned precisely behind the object, aligned with the camera’s optical axis to create the optimal silhouette. Diffusers can be used to soften the light and eliminate sharp gradients, while collimators can focus the light for more defined edges. Additionally, choosing the right lens and camera settings is essential for maximizing the benefits of backlighting.

Backlighting vs. Other Lighting Techniques

While backlighting excels at defining edges and shapes, it’s not a universal solution. Front lighting is better for capturing surface details, and side lighting is ideal for highlighting textures. In many advanced machine vision systems, a combination of lighting techniques is used—switching dynamically between them to match the inspection requirements. However, when accuracy of edge definition is paramount, backlighting remains unmatched.

Common Challenges and How to Overcome Them

Some challenges with backlighting include:

- Glare or light leakage: This can be reduced using proper shielding or collimated light sources.

- Insufficient brightness in large fields of view: High-power LEDs or multiple synchronized backlights can address this issue.

- Heat buildup: Effective thermal management extends the lifespan of high-brightness backlights and maintains performance consistency.

- By working with experienced machine vision lighting specialists, these challenges can be mitigated to ensure reliable operation.

Advancements in Backlight Technology

Recent innovations are making backlighting even more effective and energy-efficient. High-density LED arrays, advanced diffusion films, and adaptive brightness control allow for more precise tuning of light output. Some backlights now integrate with machine vision software, enabling dynamic brightness adjustment in response to real-time inspection data. This level of adaptability is especially valuable in production environments with variable product sizes, speeds, or materials.

The Impact on Overall System Performance

In a machine vision system, the backlight’s role extends beyond simply illuminating the object. By providing a clean, consistent visual input, the backlight reduces processing errors, shortens inspection times, and improves system reliability. High-contrast images require less computational effort for edge detection and measurement, enabling faster throughput without sacrificing accuracy. Over time, this efficiency can translate into significant cost savings and higher production quality.

Conclusion

Machine vision backlighting is an indispensable tool for achieving high-precision image capture in industrial automation. By delivering superior contrast, reducing visual noise, and enabling accurate silhouette imaging, a well-designed backlight significantly enhances the performance of vision systems. Whether in electronics manufacturing, packaging, automotive, or pharmaceutical production, the right backlight ensures that inspection processes are both efficient and reliable. As lighting technology continues to evolve, the potential for even greater accuracy and adaptability in machine vision systems will only expand.