Key Considerations When Selecting a Machine Vision Camera System

Understanding Application Requirements for Machine Vision Systems

Industrial Automation vs. Robotic Guidance Needs

In industrial automation and robotic guidance systems, understanding the distinct application requirements is crucial. These systems are designed with different objectives; industrial automation focuses on optimizing production processes, while robotic guidance aims at directing robots with precision in dynamic environments. Both applications demand specific features in terms of image clarity, processing speed, and integration capabilities. For instance, industrial automation might prioritize high-speed processing and robust integration with existing systems, as seen in a case study on automotive assembly lines where seamless machine vision integration is key to efficiency (source: Journal of Industrial Automation). Meanwhile, robotic guidance requires precision and adaptability in varying light conditions. Recognizing the operational environment is vital; selecting the appropriate machine vision technology often depends on factors like lighting conditions, spatial constraints, and the integration complexity of existing systems.

High-Speed Camera 1000 fps for Rapid Inspection

High-speed cameras, especially ones capable of 1000 fps, play a pivotal role in applications requiring rapid inspection, such as automotive and electronics industries. These cameras significantly boost efficiency by enabling quick analysis and assessment of fast-moving objects. Technical specifications critical to their performance include high resolution, exceptional frame rate, and superior light sensitivity, which are essential in environments with variable lighting or in capturing rapid movements with precision. In practical applications, high-speed cameras have been shown to reduce downtime and enhance inspection accuracy, as documented by a case study in the electronics sector, where transition time between inspections was cut by 40% using these advanced cameras (source: Electronics Industry Review). This highlights their importance in environments where rapid, accurate analysis is crucial for maintaining high production standards.

Environmental Factors in Harsh Manufacturing Settings

Manufacturing settings often present environmental challenges that can impede machine vision systems. Common issues include dust, vibration, and extreme temperatures, all of which necessitate robust technology capable of enduring harsh conditions. Ruggedized equipment is essential to prevent hardware failures that are often reported in hostile environments, such as those illuminated in a study on hardware longevity in manufacturing plants (source: Manufacturing Technology Journal). The performance of machine vision systems can significantly vary based on environmental conditions, making it critical to incorporate protective measures and durable designs during hardware selection. Understanding the impact of these conditions ensures the selection of machine vision cameras that are both resilient and capable of maintaining accuracy in challenging settings, thus safeguarding the long-term efficacy of industrial applications.

Selecting Image Sensors for Optimal Performance

CCD vs CMOS: Balancing Cost and Sensitivity

Choosing between CCD (Charge-Coupled Device) and CMOS (Complementary Metal-Oxide-Semiconductor) sensors involves evaluating cost-efficiency, image quality, and sensitivity. CCD sensors, traditionally known for higher image quality and better light sensitivity, can be more expensive compared to CMOS sensors. However, advancements in CMOS technology have narrow the gap, making them a popular choice due to their affordability and faster processing speeds. Studies indicate that CMOS sensors account for a significant portion of the market, showing a trend towards cost-effective and efficient solutions.

The choice of sensor significantly impacts machine vision system performance. CCD sensors offer superior image clarity, ideal for applications requiring high precision, such as medical imaging. In contrast, CMOS is suitable for consumer electronics and real-time processing needs due to their lower power consumption and faster operation. User preference studies reveal that industries requiring rapid inspection and large-scale deployment lean towards CMOS sensors for their balance of cost, speed, and acceptable image quality.

SWIR Camera Technology for Infrared Applications

SWIR (Short-Wave Infrared) cameras provide unique advantages by detecting materials and processes invisible in standard wavelengths. This technology excels in identifying moisture content, temperature variations, and material composition, making it indispensable in solar cell inspection and pharmaceutical applications. For instance, in solar energy, SWIR cameras can assess the quality of photovoltaic cells by revealing imperfections otherwise undetectable.

In the pharmaceutical industry, SWIR technology aids in ensuring product integrity by inspecting the packaging and verifying the content without physical contact. A case study showcased SWIR cameras improving inspection accuracy by up to 30% in a solar cell manufacturing plant, reducing defects and enhancing production efficiency. The ability to see beyond visible light spectrum makes SWIR cameras a critical asset in industries where precision and non-destructive testing are crucial.

Microbolometers in Thermal Imaging Systems

Microbolometers play an essential role in creating thermal images by converting infrared radiation into electrical signals, offering advantages over alternative technologies like thermopiles and pyroelectric detectors due to their compact size and cost-effectiveness. Their application spans across various sectors, including building diagnostics, where they help detect heat loss, and industrial equipment monitoring, where they assist in identifying overheating or operational faults.

Empirical evidence substantiates the efficacy of microbolometers, with thermal imaging systems reducing maintenance costs by 25% in facilities management. The demand for non-contact temperature measurement and condition monitoring is driving market trends. Microbolometer technology is expected to advance with improved resolution and sensitivity, further solidifying its role in machine vision systems. As industries prioritize energy efficiency and predictive maintenance, microbolometer-based thermal imaging systems are set to see substantial growth.

Optimizing Inspection Spectrum and Lighting Solutions

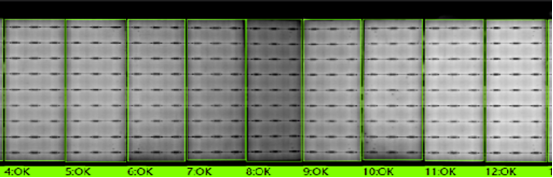

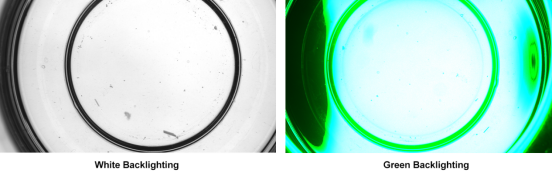

Machine Vision Lighting for Contrast Enhancement

Lighting is crucial in machine vision systems as it directly influences image contrast and the ability to detect defects. Effective lighting solutions are necessary to enhance visibility which is often achieved by altering contrast. For instance, backlighting and incident lighting techniques can greatly improve object visibility. Backlighting, by illuminating the object from behind, highlights its silhouette, while incident lighting illuminates from various angles to accentuate surface features and textures. In practical terms, using appropriate lighting can significantly improve defect detection rates. Case studies have demonstrated drastic improvements in inspection processes by simply optimizing lighting conditions, transforming unclear images into highly detailed and observable visuals.

UV vs Visible Light for Defect Detection

Comparing UV and visible light for defect detection reveals different strengths and weaknesses in various industrial settings. UV light is particularly effective in detecting surface-level defects like scratches or impurities that are often invisible under regular lighting conditions. Conversely, visible light is better suited for identifying color discrepancies and surface textures. For instance, in the automotive industry, UV light is preferred for checking safety glass surfaces, whereas visible light might be more effective for detecting paint inconsistencies. Empirical testing consistently supports these assertions, highlighting the importance of choosing the correct light spectrum based on the specific application needs. The decision of whether to use UV or visible light often depends on the nature and location of the defect being inspected.

Multi-Spectral Imaging in Quality Control

Multi-spectral imaging expands analysis capabilities beyond traditional RGB imaging by capturing data across several wavelengths. This technology allows for more detailed material analysis, revolutionizing quality control processes in industries like food safety and textiles. For example, in the food industry, multi-spectral imaging can reveal issues like contamination or decay that are invisible to the naked eye. Textile manufacturers similarly benefit from this technology in detecting variations in fiber compositions and dyes. Research studies corroborate the efficacy of multi-spectral imaging, often showcasing significant improvements in defect detection rates. This technology not only refines quality control standards but also advances the operational efficiency within these industries.

Integration Considerations for Seamless Operation

GigE vs USB 3.0 Interface Selection

Choosing between GigE and USB 3.0 interfaces for camera systems is crucial in determining data transfer efficiency and overall application performance. GigE offers high-speed data transfer rates and longer cable lengths, making it suitable for large setups. However, its performance can be affected by network congestion. In contrast, USB 3.0 offers ease of use with plug-and-play capabilities, but its cable length is limited to about 3 meters.

When considering specific scenarios, GigE is ideal for applications that require high-speed data over long distances without bandwidth constraints, such as high-speed imaging and industrial automation. On the other hand, USB 3.0's simplicity makes it a solid choice for laboratory settings or small-scale operations. Recent trends show a growing preference for GigE due to its network flexibility and extensive range, with case studies highlighting its advantage in complex industrial settings where cable management is crucial.

Welding Camera Durability in Extreme Conditions

Welding cameras face extreme conditions, requiring robust durability to withstand harsh environments. High temperatures, spatter, and vibrations are common challenges that welding cameras must endure. Therefore, using materials like heat-resistant alloys and durable ceramics enhances longevity and performance. Design features such as protective housing and shock-absorbing mounts also play a key role in extending the life of these cameras.

Real-world examples, such as welding camera setups in automotive manufacturing, showcase their effectiveness when equipped with durable casings and advanced cooling systems. These elements ensure consistent image quality and operational efficiency, even in high-temperature welding operations. Industry tests have validated these designs, proving that robust construction significantly reduces maintenance costs and prolongs equipment lifespan.

Synchronizing Cameras with Robotic Controllers

The synchronization of cameras with robotic controllers is vital for achieving precision in automated processes. Proper alignment between these components ensures accurate timing and movement coordination, which is essential in tasks like assembly, inspection, and material handling. Techniques for synchronization include using dedicated hardware clock signals or advanced software algorithms to harmonize the operation of both systems.

Successful implementations often involve integrating synchronization modules that bridge communication between cameras and robot controllers. For example, automotive manufacturing lines have benefitted from precise camera-robot coordination, enhancing the accuracy and speed of component assembly. Several case studies demonstrate that effective synchronization not only optimizes production line efficiency but also reduces error rates, proving invaluable in high-precision environments.