Optimizing Image Contrast: Machine Vision Lighting Techniques Demystified

Optimizing Image Contrast: Machine Vision Lighting Techniques Demystified

The Role of Lighting in Machine Vision Image Contrast

Why Lighting is Critical for Contrast Optimization

Lighting plays a pivotal role in machine vision as it directly influences image quality and contrast optimization. Proper illumination is essential for highlighting features and textures within an image, which significantly enhances image contrast. Optimal lighting ensures that machine vision systems capture high-quality images, thus enabling accurate analysis and decision-making. Studies show that up to 90% of a vision system's performance is dependent on adequate lighting conditions. This highlights the importance of selecting the correct lighting solutions for specific applications to achieve superior results in industrial automation.

How Lighting Techniques Impact Defect Detection

Different defects in materials and products require specific lighting techniques for effective detection. Techniques such as backlighting and spotlighting can be employed to emphasize surface imperfections and defects. For instance, backlighting can be beneficial in applications where silhouettes need to be highlighted, while spotlighting can help in identifying surface dents or scratches. Research indicates that optimizing lighting in machine vision applications can improve defect detection rates by as much as 30%. This underscores the necessity of adopting appropriate lighting strategies to enhance the accuracy and efficiency of defect detection processes, thereby minimizing errors and improving overall quality control.

Bright Field vs. Dark Field Lighting Techniques

Bright Field Lighting: Principles and Applications

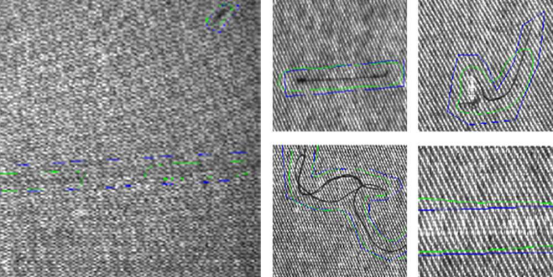

Bright field lighting involves illuminating the entire field of view, making it ideal for analyzing homogeneous samples. This approach is particularly advantageous when inspecting flat surfaces, textiles, and materials where color and texture play a crucial role. For instance, in the textile industry, bright field lighting helps in examining weave patterns and dye consistency. As experts in machine vision confirm, bright field lighting is preferred in applications that demand high color fidelity due to its ability to deliver clear and consistent colors. This lighting technique shines by eliminating the shadows cast by surface irregularities, resulting in a bright, well-defined image that aids in precise inspection processes.

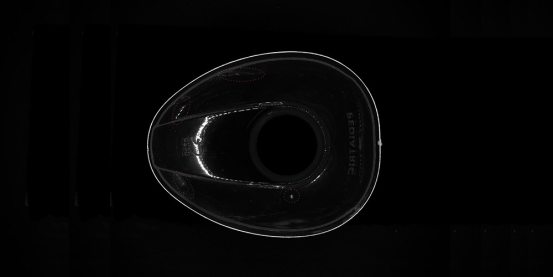

Dark Field Lighting: Enhancing Edge and Surface Defects

Unlike bright field lighting, dark field lighting emphasizes edges and surface irregularities by capturing scattered light. This is particularly beneficial for detecting flaws in transparent and semi-transparent materials. For example, dark field lighting can enhance the visibility of defects in glass or plastic, which are typically challenging to detect with other lighting techniques. Case studies suggest that using dark field lighting markedly improves edge detection by highlighting areas where light is scattered rather than reflected. This makes it a preferred choice for industries where precision in identifying surface defects is critical, such as in semiconductor manufacturing and quality control of optical lenses.

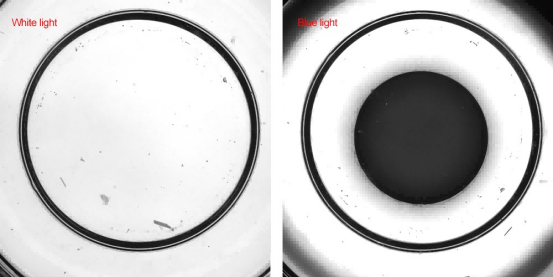

When to Choose Bright Field vs. Dark Field

Selecting the appropriate lighting technique is contingent on the material properties and the type of defects being targeted. Generally, bright field lighting is recommended for applications focused on color inspection, while dark field lighting excels in enhancing edge details. For scenarios that require a comprehensive analysis, combining both techniques can yield optimal results. This dual approach allows for a meticulous examination of both surface quality and subtle irregularities, making it particularly effective in complex inspection tasks. By understanding the specific requirements of your application, you can make an informed choice between these lighting methods, ensuring efficient and accurate image analysis.

Optimizing Camera Settings for Enhanced Contrast

PRNU Calibration for Bright Field Precision

Photo Response Non-Uniformity (PRNU) calibration is essential for ensuring consistent brightness levels across images captured in bright field lighting scenarios. By addressing variations in pixel sensitivity, PRNU calibration enhances the uniformity of the image. Detailed calibration guides suggest that even minor adjustments to PRNU settings can lead to noticeable improvements in image quality. Experts in the field recommend conducting regular calibration sessions to maintain high levels of imaging precision, thereby ensuring that machine vision systems deliver accurate and reliable results consistently.

DSNU Calibration for Dark Field Accuracy

Dark Signal Non-Uniformity (DSNU) calibration plays a critical role in maintaining consistency and accuracy in dark field applications. This calibration process helps in reducing noise and false positives, thereby enhancing the detection of surface defects. Evidence from various studies shows that proper DSNU calibration significantly improves the reliability of defect detection by mitigating inconsistencies caused by variations in the dark current signal. To ensure ongoing accuracy and integrity in dark field imaging, regular calibration checks and adjustments are vital.

Balancing Gain and Exposure for Optimal Results

Balancing camera gain and exposure settings is crucial for achieving optimal image saturation and clarity. Properly adjusting these settings allows for enhanced contrast, enabling clearer distinction of features within the image. Step-by-step procedures provide guidance on optimizing camera settings under different lighting conditions, which can effectively reduce noise and improve image quality. Analytical insights suggest that tailored adjustments in gain and exposure can enhance performance, allowing machine vision systems to deliver superior results in diverse operational environments.

Advanced Techniques: Wavelength and Angle Optimization

Selecting Light Colors for Material Differentiation

Selecting appropriate light colors based on wavelengths is crucial for effective material differentiation in machine vision applications. Different wavelengths interact uniquely with materials, aiding in their identification. For instance, using specific colors of light can significantly enhance feature visibility — blue light is particularly effective for certain plastics. Industry studies advocate for experimentation with light colors tailored to the materials in use, emphasizing the importance of adjusting the color spectrum to meet specific needs. This approach not only enhances imaging quality but also improves the accuracy and efficiency of inspection processes.

Angle of Illumination: Minimizing Glare, Maximizing Detail

Adjusting the angle of illumination is vital for minimizing glare and maximizing the visibility of surface textures. When direct lighting causes extensive glare, tactical angle setups can reveal features otherwise obscured. This can significantly enhance the quality of surface inspections across various applications. Professional engineers often recommend measuring angles during setup to ensure optimal results. By strategically positioning light sources, both glare reduction and detail enhancement can be achieved, supporting better image analysis and detection accuracy.

Infrared and UV Lighting for Specialized Applications

Infrared and ultraviolet (UV) lighting play an essential role in specialized applications, providing unique imaging capabilities. Infrared lighting is effective for detecting certain materials invisible to the naked eye, especially in low-light conditions, making it invaluable in night vision and security surveillance. On the other hand, UV lighting can reveal surface defects and coatings, aiding in thorough inspections particularly within electronics and material sciences. Such applications underscore the importance of these technologies in enhancing imaging capabilities beyond conventional methods, ensuring detailed and accurate inspections.