Optimizing Lighting Solutions for Accurate Machine Vision Applications

The Critical Role of Lighting in Machine Vision Accuracy

Why Lighting is the Foundation of Reliable Machine Vision

Lighting is an essential element that influences image acquisition and analysis in machine vision applications. Proper illumination can significantly enhance the visibility of features critical for accurate measurements and identification. Without adequate lighting, even the most advanced machine vision systems can struggle to produce reliable results. In fact, research indicates that up to 70% of machine vision system failures are due to inadequate lighting conditions. This statistic underscores the paramount importance of understanding how to harness lighting effectively as part of any machine vision setup. Different lighting techniques can be tailored to optimize specific applications; for example, ring lights are ideal for providing uniform illumination for circular objects, while directional lighting is excellent for highlighting surface features vital in many inspection tasks.

Common Challenges in Machine Vision Lighting Design

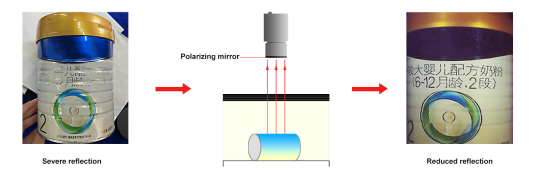

Creating a lighting setup that achieves uniformity and consistency across the field of view is a major challenge in machine vision applications. Inconsistent results often arise from poor lighting design, making it crucial to select appropriate lighting types and position them correctly. Moreover, glare and reflections pose significant issues during image capturing, introducing noise into machine vision systems. Addressing these involves thoughtful positioning and the use of diffusers to manage these factors effectively. Different environments also bring unique challenges; for instance, ambient light interference is common in factory settings. To counteract this, implementing controlled lighting environments can ensure consistent performance from the machine vision system.

Types of Machine Vision Lighting Solutions

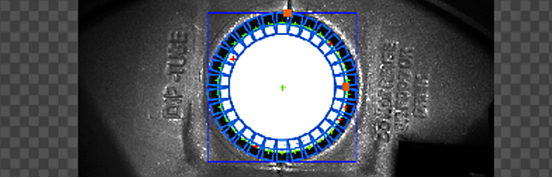

Ring Lights for Uniform Circular Illumination

Ring lights are prominently used in machine vision applications because they provide even and shadow-free lighting for cylindrical or circular objects. This characteristic ensures that features are well-defined and easier to analyze, which is crucial in achieving high precision and accuracy in imaging. These lights can be adjusted for varying intensity levels, making them versatile for different materials and surface properties, supporting diverse applications from electronics assembly to medical device inspections. Importantly, installing ring lights directly at the lens of the camera helps to reduce shadows and improve the accuracy of the captured images, ensuring optimal circular illumination.

Dome Lights for Diffuse Reflective Surface Imaging

Dome lights are ideal for illuminating complex shapes and surfaces, producing diffuse reflections that minimize shadows. This property is crucial for inspecting non-uniform surfaces in industries like automotive and packaging, where detecting imperfections such as scratches or dents is vital. They offer advantages in reducing glare, significantly enhancing the visibility of surface defects that might otherwise go unnoticed. Selecting the right dome light requires careful consideration of the size and curvature of the object to ensure comprehensive coverage and optimal imaging conditions for accurate analysis.

Bar Lights for Large Surface Area Coverage

Bar lights are particularly useful for applications requiring uniform illumination over large surfaces, making them a preferred choice in the inspection of flat and wide objects like panels and sheets. They can be configured in various orientations and can either be installed above the object or integrated into the automation line to achieve desired lighting effects. An additional benefit of bar lights is their ability to coordinate with high-speed cameras, facilitating precise inspections that align with fast production processes. These features make bar lights indispensable in scenarios that demand extensive surface coverage and consistent lighting.

Key Factors for Selecting Optimal Lighting

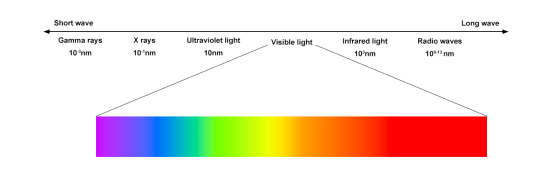

Wavelength Selection for Material Interaction

Choosing the right wavelength of light is critical for interacting effectively with different materials. Optimal wavelength selection can maximize contrast and minimize reflections based on specific surface properties. For instance, infrared lighting is often used to inspect reflective or transparent materials, providing clear images that visible light might struggle to capture. By understanding the spectral range and its interactions with various materials, we can enhance the efficiency of machine vision applications. This foundational aspect of lighting design ensures that systems deliver precise and reliable imaging.

Intensity Control and Dynamic Range Optimization

Dynamic range optimization, involving the adjustment of lighting intensity, is crucial for accommodating varying reflectivity and surface conditions. This ensures clearer image quality during machine vision inspections. Implementing intensity control technologies, such as LED drivers, allows for real-time adjustments, especially vital in environments where lighting conditions change rapidly, such as manufacturing settings. Research shows that systems with dynamic intensity control can increase inspection accuracy by up to 30%, highlighting the importance of adaptive lighting solutions in improving inspection outcomes.

Angular Positioning to Minimize Glare

Strategically positioning lighting sources at specific angles is essential for minimizing glare, an effect that can obscure critical image details and reduce the efficacy of machine vision systems. Techniques such as cross-polarization and angle-based adjustments are employed to enhance the visibility of key features, making them more discernible during analysis. Testing different angular setups is necessary to determine which configuration provides optimal results for specific inspection tasks, ensuring that imaging is both clear and accurate.

By understanding these key factors, we can effectively optimize our machine vision lighting solutions to improve image quality and system performance.

Synchronizing High-Speed Cameras with Lighting Systems

Pulse Timing for Motion-Freeze Applications

In high-speed imaging applications, precise pulse timing between lighting systems and cameras is crucial for capturing clear images of fast-moving objects. This synchronization is vital in areas such as manufacturing inspections and sports analysis, where clarity and detail are paramount. Using pulsed lighting can effectively freeze motion, allowing for detailed inspections and ensuring that every frame captures the subject clearly. Studies have shown that proper synchrony can increase the accuracy of object detection by up to 25%, underlining the importance of timing in high-speed machine vision. This approach makes a difference by ensuring that rapid movements are documented with accuracy, enhancing the capabilities of machine vision lighting systems.

Stroboscopic Techniques for Rapid Inspection

Stroboscopic lighting techniques utilize short bursts of light to enhance the visibility of fast-moving subjects, making them ideal for assembly line inspections where speed is critical. This method allows for capturing high-resolution images of rapid motions, which is beneficial in applications like quality control and robotics, where precision and speed are necessary. Implementing stroboscopic lighting properly can significantly improve throughput and inspection accuracy, confirming its relevance in modern machine vision technologies. Its success lies in its ability to maintain clarity and precision amid rapid movement, offering significant advantages in industries that demand swift and accurate inspections. Studies emphasize its effectiveness in increasing processing speed while maintaining high accuracy in defect detection.