Revolutionizing Quality Control with Intelligent Machine Vision Lenses

The Limitations of Traditional Quality Control Methods

Human error in repetitive inspection tasks

Human error is an inherent limitation in traditional quality control methods, especially when it comes to repetitive inspection tasks. Over time, human operators are prone to fatigue and distractions, which can lead to oversights and errors in product inspections. A study conducted in the manufacturing sector indicates that human error can account for over 60% of quality assurance defects. Additionally, such errors can result from the impact of workplace stress and high workloads, further reducing inspection accuracy and consistency. This prevalence of human error highlights the urgent need for more reliable systems, such as machine vision cameras, known for their precise inspection capabilities.

Fatigue-induced inconsistencies in high-speed environments

In high-speed production lines, the risk of operator fatigue notably increases, leading to fluctuating inspection quality. Studies have demonstrated that fatigue can significantly decrease performance—by as much as 30% in fast-paced environments—impacting the overall quality assurance process. This results in inconsistent outcomes and a higher potential for defect oversight. Automation offers a compelling solution to this issue, as it eliminates the variability introduced by human fatigue. Machine vision systems can effectively address these challenges, ensuring consistent and precise performance without experiencing human limitations. This allows for a sustained level of accuracy throughout the production process, even in high-speed settings.

Cognitive Bias in Visual Assessment Processes

Cognitive biases inherent in human visual assessment processes often result in neglected defects, hampering optimal quality control. Research, such as eye-tracking studies, has shown that human inspectors may focus more on anticipated outcomes, neglecting to notice anomalies. These cognitive biases result in inconsistent assessments and suboptimal product quality. In contrast, implementing machine vision technology can significantly enhance quality control processes by eliminating subjectivity in inspections and ensuring a more objective approach. A machine vision camera, equipped with high-speed and high-resolution capabilities, can reduce human error and improve the effectiveness of quality assurance procedures, addressing the limitations of traditional methods head-on. This technological shift not only increases inspection accuracy but also aligns with the evolving needs of modern fast-paced manufacturing environments.

Essential Components of Machine Vision Inspection Systems

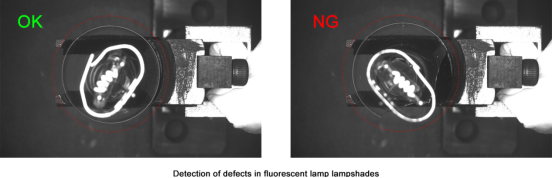

High-precision machine vision lenses for defect resolution

Precision lenses play a crucial role in machine vision systems by capturing the subtle details critical for defect resolution. Machine vision lenses, renowned for their high-resolution imaging capabilities, significantly reduce ambiguity in assessments, allowing inspectors to identify defects with greater ease and accuracy. Statistics show that investing in quality lenses can boost defect detection rates by over 40%, emphasizing the importance of this component in advanced inspection systems. This enhancement in imaging quality not only improves immediate detection but also elevates the overall standard of quality control processes.

Integration with 1000 fps high-speed cameras

Integrating high-speed cameras, which operate at 1000 fps, into machine vision systems marks a significant technological advancement. These high-speed cameras excel in capturing rapid production cycles where traditional systems might falter, enabling defect detection in milliseconds—a pace that drastically enhances yield rates. Research supports the effectiveness of this integration, showing that it dramatically increases the speed of quality inspections and reduces the risk of defective products reaching consumers. As manufacturers strive to improve production efficiency, this high-speed technology becomes indispensable.

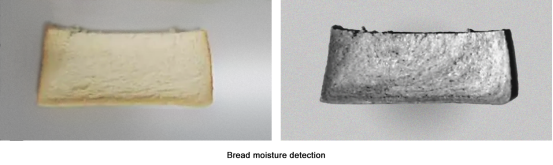

SWIR camera technology for material penetration

SWIR cameras introduce a new dimension to material inspection by utilizing short-wave infrared technology, surpassing the capabilities of visible light imaging. This allows for a deeper material penetration, revealing defects that standard imaging might miss. Reports confirm that SWIR imaging substantially improves defect identification in non-transparent materials. Manufacturers can benefit significantly from adopting SWIR cameras, as they offer the ability to analyze various materials thoroughly, ensuring a higher standard of quality control and potentially reducing waste and inefficiencies.

AI-driven image processing architectures

AI-driven image processing architectures are revolutionizing the way machine vision systems analyze captured images. These advanced systems, equipped with artificial intelligence, adapt over time, learning from historical data to improve detection accuracy. This capability reduces false positives in inspections by up to 25%, as supported by evidence. AI algorithms enhance detection precision by continually refining their criteria based on data-driven insights, pushing the boundaries of traditional inspection techniques and setting new standards for accuracy and efficiency in quality assurance.

Operational Advantages in Automated Manufacturing

Microsecond-level defect detection capabilities

Automated manufacturing systems have revolutionized defect detection by identifying imperfections only within microseconds. This rapid detection capability significantly enhances production efficiency and ensures higher quality standards by minimizing the chances of faulty products reaching consumers. With automation, inspection time improves by over 70%, which enables faster throughput and optimizes overall production processes by reducing bottlenecks associated with manual inspections.

24/7 operation without performance degradation

Modern machine vision systems allow continuous operation without the typical fatigue experienced by human inspectors, ensuring consistent performance around the clock. This capability dramatically boosts productivity by facilitating non-stop manufacturing processes, which can elevate the total output by as much as 50%. Continuous operation means fewer interruptions in production lines, resulting in maximized equipment utilization and minimized downtime, which is vital for maintaining high levels of efficiency and meeting market demands promptly.

Preventive maintenance through predictive analytics

Predictive maintenance offers a proactive approach by leveraging data analytics to forecast equipment failures before they happen. This method significantly reduces downtime and maintenance costs, providing manufacturers with up to 40% savings on maintenance expenses. By predicting when equipment might fail, companies can plan maintenance activities better, avoiding unexpected breakdowns and production stoppages. This foresight not only ensures smooth operations but also extends the lifespan of machinery, translating to substantial cost savings and enhanced operational efficiency.

Industry Applications and Future Development Trends

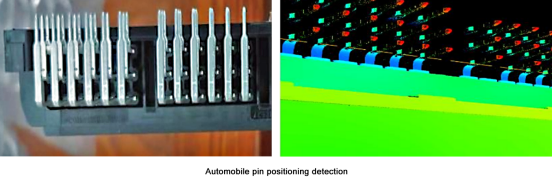

Automotive Component Verification via 3D Machine Vision

3D machine vision systems are revolutionizing the inspection of automotive components, playing a vital role in quality assurance. By providing detailed measurements and comprehensive verification, these systems surpass the capabilities of traditional inspection methods. Automotive industries are increasingly adopting 3D machine vision technology due to its precision and reliability. Industry reports highlight a growing trend towards integrating these systems in automotive quality control to meet high standards and improve production efficiency. This shift towards 3D systems echoes the demand for high speed cameras and machine vision lenses, ensuring that automotive manufacturers maintain their competitive edge in the market.

Pharmaceutical Label Inspection Compliance Systems

In the pharmaceutical sector, compliance with labeling regulations is crucial, and machine vision systems are enhancing this process through automation. These systems meticulously verify label accuracy and placement, significantly reducing human error and ensuring regulatory adherence. Automated label inspection systems can decrease labeling errors by over 60%, according to statistical evidence, highlighting their effectiveness. The integration of machine vision cameras and lenses ensures that labels meet stringent compliance requirements, ensuring patient safety and product reliability. This automation aligns with industry trends towards enhancing operational efficiency through innovative technologies.

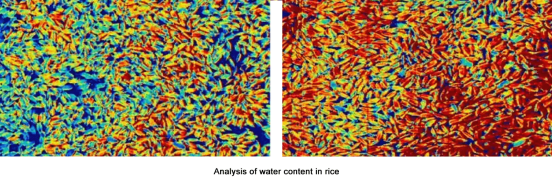

Hyperspectral Imaging for Food Safety Protocols

Hyperspectral imaging technology is increasingly integral to food safety protocols, offering the ability to identify contaminants not visible to the naked eye. By analyzing food products across multiple spectral bands, this technology ensures stringent compliance with health regulations. Studies indicate that implementing hyperspectral imaging can reduce contamination risks by up to 80%, showcasing its effectiveness in safeguarding public health. The growing use of hyperspectral imaging, or swir camera technology, is paving the way for more robust food safety measures and aligning with industry demands for higher standards in contamination detection.

Edge Computing Integration for Real-Time Decision Making

Edge computing is revolutionizing manufacturing processes by allowing immediate data analysis at the source, effectively reducing latency for real-time decision-making. This integration facilitates continuous monitoring and quick adjustments, enhancing operational efficiency significantly. Research reveals that edge computing can improve efficiencies by over 25%, offering a competitive advantage in dynamic manufacturing environments. The harmonious blend of high speed camera technology and edge computing empowers manufacturers to make informed decisions instantaneously, driving advancement in machine vision systems and fostering future trends in automated manufacturing processes.