Speed and Accuracy: How Machine Vision Cameras Optimize Production Line Throughput

Speed and Accuracy: How Machine Vision Cameras Revolutionize Production Line Throughput

Modern manufacturing faces a relentless challenge: accelerating output without compromising quality. As production lines push for higher speeds, traditional inspection methods often become bottlenecks. Machine vision cameras resolve this dilemma through unprecedented speed, precision, and adaptability, directly optimizing throughput across industries.

The Throughput-Killer: Why Speed and Accuracy Conflict

Production lines frequently sacrifice quality for velocity or vice versa. Human inspectors might struggle to maintain accuracy beyond 60 parts/minute, while high-speed automated systems using outdated sensors could overlook sub-millimeter defects. In sectors like electronics or pharmaceuticals, a single undetected flaw could trigger recalls costing millions. Excessive false rejects further inflate waste—precisely where machine vision cameras redefine possibilities.

Unlocking Dual Capabilities: The Machine Vision Advantage

Machine vision cameras conquer the speed-accuracy tradeoff through two core innovations:

- Velocity Engineered for Motion Global shutter technology eliminates motion blur at conveyor speeds exceeding 5 m/s. Coupled with 200+ fps frame rates, these cameras capture crisp images of fast-moving objects—whether automotive components on assembly lines or blister packs in pharmaceutical filling stations. Manufacturers could achieve near-zero latency inspection, synchronizing seamlessly with robotic arms for real-time rejection or sorting.

2. Microscopic Precision, Macro Impact High-resolution sensors (5MP–20MP) paired with multi-spectral imaging detect defects invisible to conventional optics. Short-wave infrared (SWIR) cameras, for instance, could identify contaminants in transparent materials, while HDR capabilities reveal cracks on reflective metal surfaces. One European automotive supplier reduced false rejects by 40% after deploying such systems in gear inspection.

Customized Solutions for Critical Applications

Machine vision cameras deliver maximum ROI when tailored to specific industrial challenges:

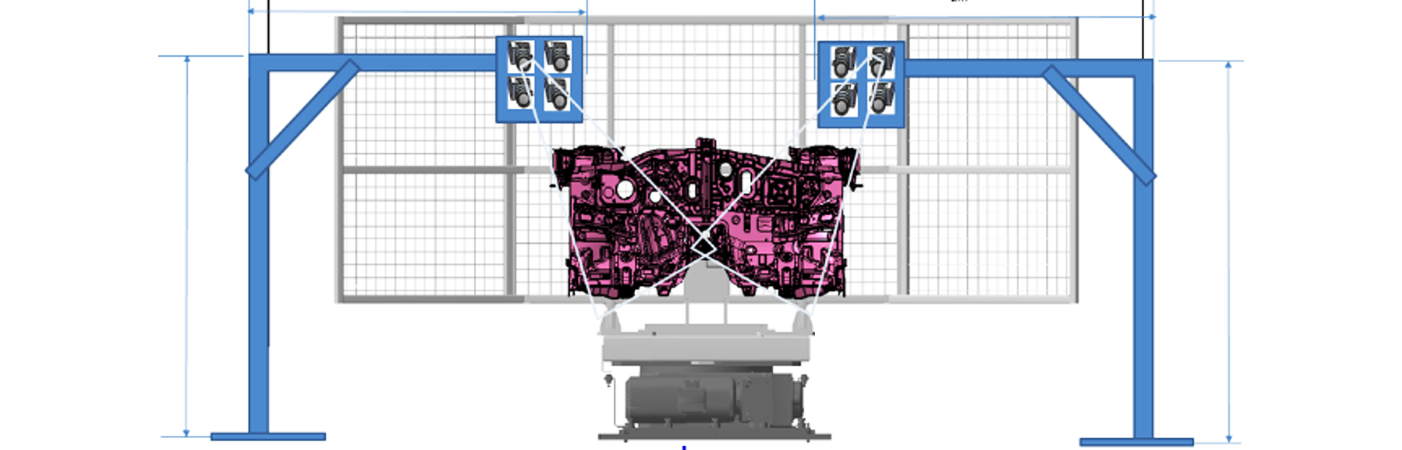

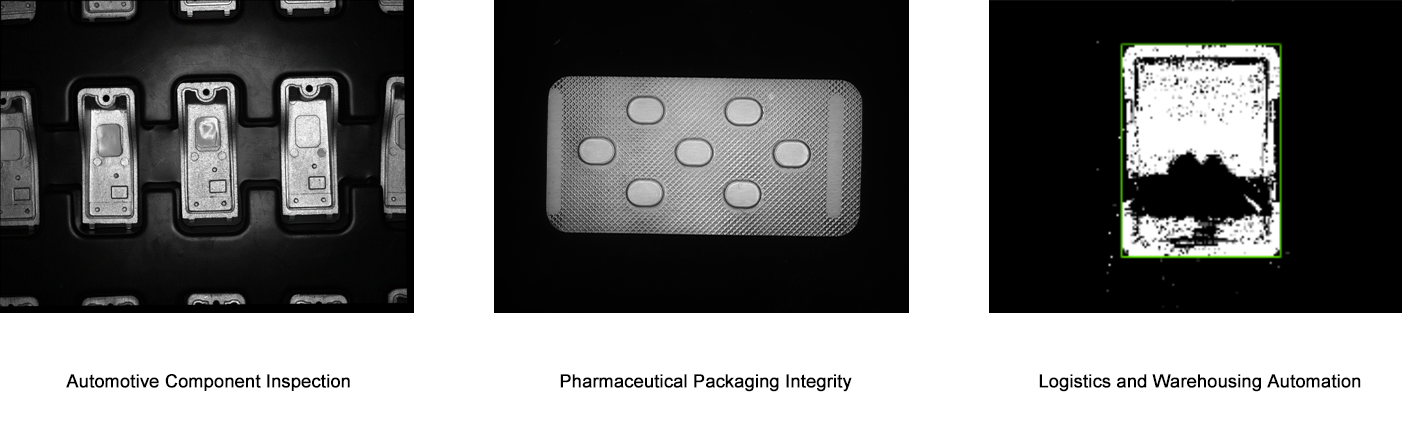

Automotive Component Inspection High-dynamic-range cameras with polarized lighting can identify sub-0.1mm scratches on machined parts. A global Tier 1 supplier achieved 99.2% defect detection at 0.8 seconds/part—accelerating throughput by 35% while slashing annual rework costs.

Pharmaceutical Packaging Integrity For vial sealing or blister pack checks, backlit micro-imaging solutions pinpoint pinhole leaks as small as 10μm. A leading pharma company eliminated 90% of leakage-related recalls using vision-guided verification integrated into filling lines.

Logistics and Warehousing Automation 3D time-of-flight (ToF) cameras combined with deep learning enable robotic arms to identify, locate, and handle diverse parcels at 2,000+ units/hour. This could eliminate manual sorting bottlenecks in e-commerce fulfillment centers.

Quantifying Impact: Beyond Technical Specs

The strategic value of machine vision cameras manifests in measurable production gains:

- Throughput Amplification: Faster inspection cycles allow lines to safely increase speed without quality loss.

- Zero-Cost Quality: Reducing false rejects cuts material waste, while higher defect capture prevents downstream failures.

- Agile Manufacturing: Rapid reconfiguration capabilities support small-batch production via software-driven changes.

One consumer electronics manufacturer reported 22% higher OEE (Overall Equipment Effectiveness) within six months of deployment, attributing gains to minimized unplanned downtime and near-perfect first-pass yield.

For production engineers seeking to break speed-accuracy barriers, the path forward lies in purpose-built vision solutions. HIFLY’s modular camera systems, adaptable optics, and intelligent lighting could unlock your production line’s latent capacity—turning throughput ambition into operational reality.