Applications of Polarization Cameras in Industrial Vision Inspection

In industrial vision inspection, "glare" and "hidden defects" are two major nightmares for conventional cameras: strong reflections from metal part surfaces make scratches "invisible," glare on transparent glass obscures internal bubbles, and stress marks on plastic parts are completely undetectable with standard cameras. These issues lead to missed defect rates as high as 15%, necessitating manual re-checking, which severely slows down production.

Polarization cameras, leveraging their unique ability to "filter polarized light and highlight subtle differences," act like an "anti-glare filter + defect magnifier" for the camera. They easily solve problems that conventional cameras struggle with.

This article breaks down the core application scenarios of polarization cameras in industrial inspection, combining technical principles with real-world cases to help you understand "why they can eliminate reflections and reveal defects."

I. The "2 Core Capabilities" of Polarization Cameras

Many people think "polarization cameras are just for reducing glare," but overlook their core value lying in the "interaction between polarized light and materials." These two capabilities directly address the shortcomings of conventional cameras:

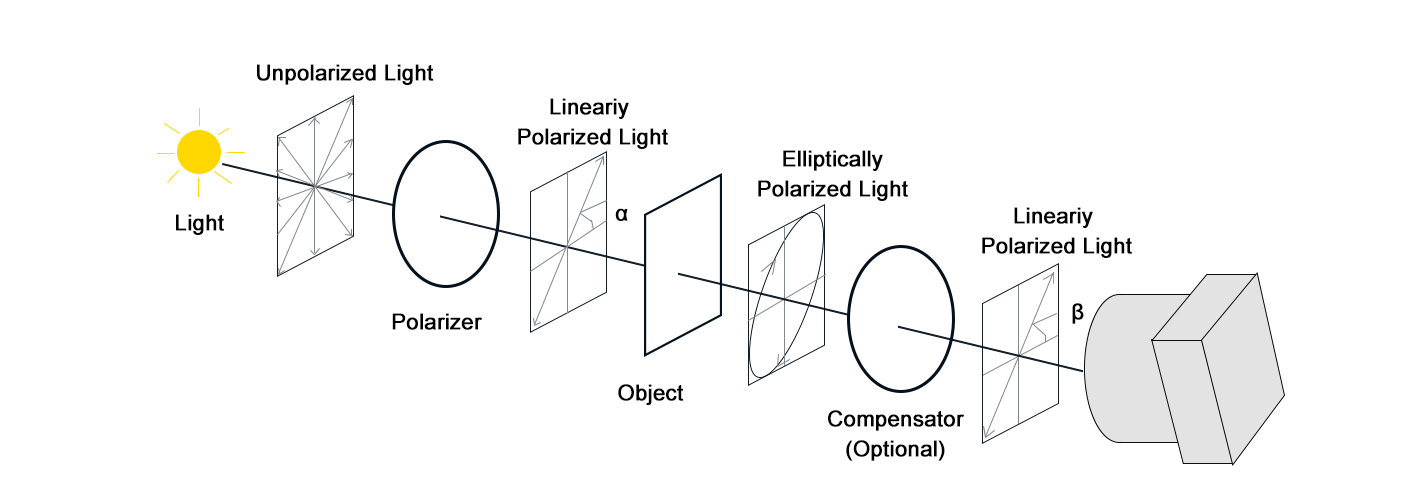

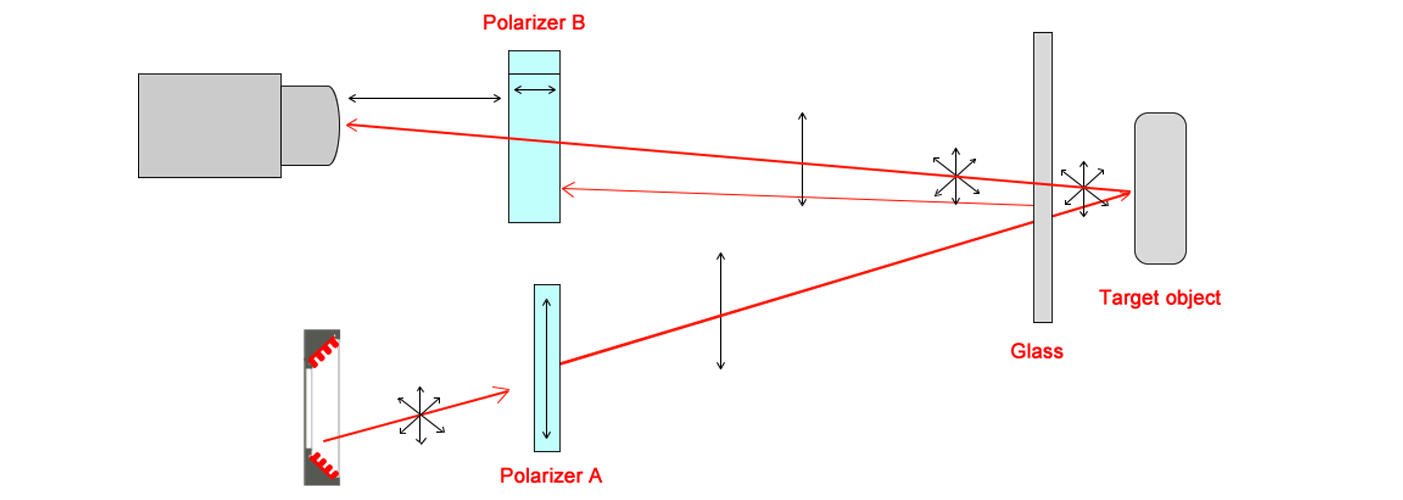

1. "Directional Glare Elimination" to remove reflection/glare interference: Light reflected from smooth surfaces like metal, glass, and plastic is often "polarized light" (light vibrating in a single plane). Polarization cameras can filter out polarized light in specific directions by adjusting the polarizer angle, causing reflective areas to "darken" and defect details to "stand out" (e.g., metal scratches become visible amidst reflections).

2. "Revealing Hidden Features" to identify invisible differences: Hidden characteristics like internal stress in transparent components, plastic texture, or coating uniformity cause transmitted light to undergo changes in "polarization state" (change in vibration direction). Polarization cameras can capture this change, converting hidden features into images with "contrast in brightness" (e.g., glass stress marks appear as colored fringes).

Simply put: Scenes where conventional cameras are "blinded by glare and cannot see hidden defects" are the "primary battlefield" for polarization cameras.

II. Core Application Scenarios in Industrial Vision Inspection

Polarization cameras aren't a "universal tool," but their advantages are irreplaceable in scenarios with "severe glare or the need to identify hidden features," specifically applied across various industrial fields:

1. Scenario 1: Metal Part Surface Defect Inspection – Eliminating Glare to Reveal Scratches/Dents

• Pain Point: Surface scratches, dents, and burrs on automotive parts (e.g., engine blocks, transmission gears) and hardware tools (e.g., cutters, bearings) are often "drowned out" by bright spots due to strong reflections from smooth metal surfaces under conventional cameras, leading to missed detection rates up to 20%. Manual inspection requires repeatedly adjusting angles to find less reflective spots, taking 5 minutes per part, is highly inefficient, and prone to fatigue-related errors.

• Polarization Camera Solution:

(1). Technical Principle: Reflections from metal surfaces are often "linearly polarized light." By adjusting the camera's polarizer angle to be perpendicular to the reflection's polarization direction, over 90% of the glare can be filtered out. Light from scratches/dents scatters randomly (unpolarized) and isn't filtered, appearing as "clear bright lines/dark spots" against a dark background, making defects obvious.

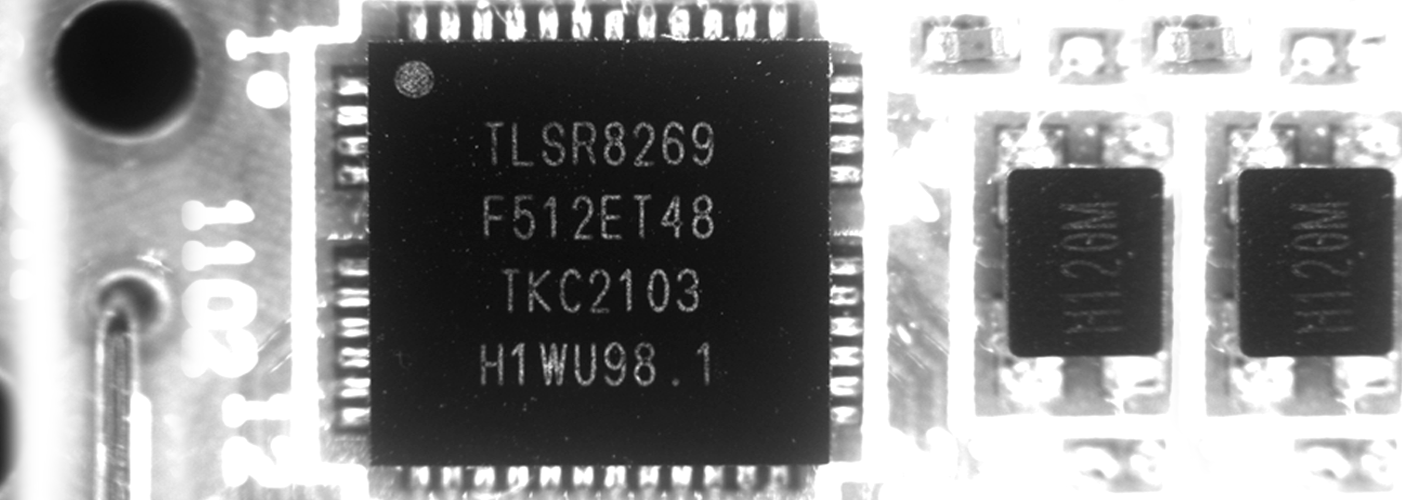

(2). Hardware Setup: Use a 5MP linear polarization camera (adjustable polarization angle 0-360°) + ring light (uniform illumination, reduces hotspots) + macro lens (magnifies defect details like 0.1mm scratches).

• Implementation Effect:

A transmission gear surface scratch inspection (scratch depth ≥0.05mm):

(1). Traditional Method: Conventional camera + manual re-inspection, 5 minutes/gear, 20% missed rate (fine scratches hidden by glare), daily rework losses >¥10,000.

(2). Polarization Camera Method: Automated glare-elimination inspection, 10 seconds/gear, detects fine 0.05mm scratches, missed rate reduced to 0.5%, efficiency increased 30x, daily rework savings ~¥9,500, annual savings >¥3 million.

• Suitable Scenarios: Surface scratch, dent, burr inspection on automotive metal parts, hardware tools, stainless steel products, aerospace metal components.

2. Scenario 2: Transparent/Semi-Transparent Part Inspection – Removing Glare to See Internal Bubbles/Impurities

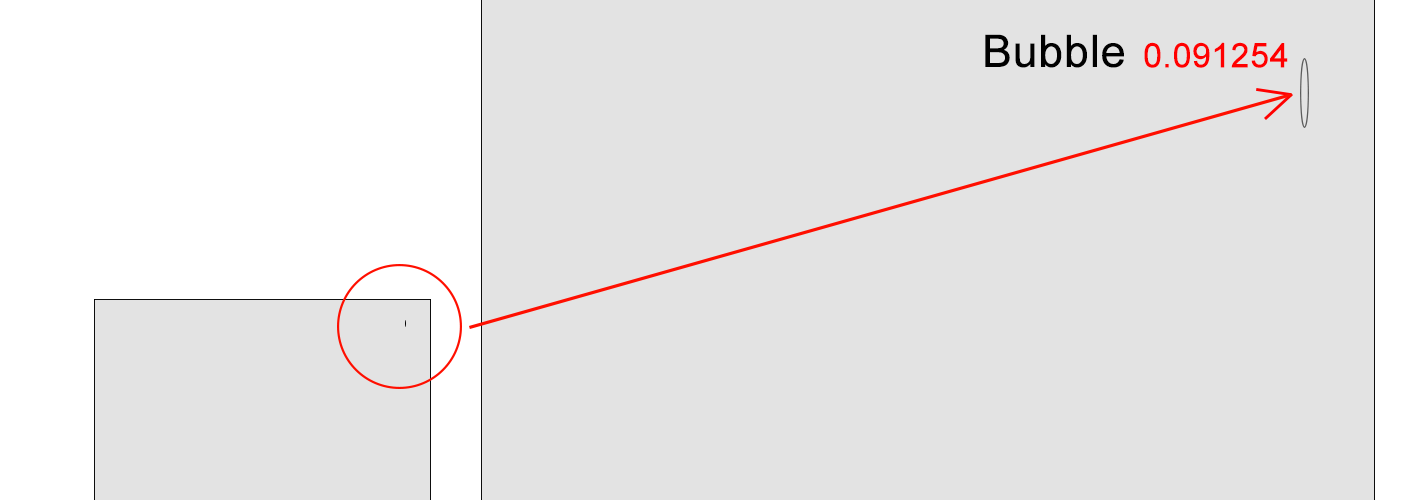

• Pain Point: For products like mobile phone glass covers, photovoltaic glass, plastic bottles, and optical lenses, "surface glare" and "internal reflections" when captured by conventional cameras obscure internal bubbles, impurities, and cracks. A 0.1mm bubble in phone glass might be just a blur of glare. Manual inspection requires dark boxes and specific lighting angles, is slow (30 seconds/glass), and prone to misses.

• Polarization Camera Solution:

(1). Technical Principle: Filtering out the surface glare (often polarized) allows clear capture of "light scattering by internal defects." Bubbles/impurities cause scattered light (unpolarized), appearing as "dark spots"; cracks alter light refraction, appearing as "dark lines," completely free from glare interference.

(2). Hardware Setup: Use a 12MP area scan polarization camera (high resolution for fine defects) + coaxial light (reduces surface reflections) + glass conveyor (constant speed for high-speed inspection).

• Implementation Effect:

Internal bubble inspection in mobile phone glass covers (bubble diameter ≥0.1mm):

(1). Traditional Method: Conventional camera + manual dark box inspection, 30 seconds/glass, 15% missed rate (small bubbles hidden by glare), >200 scrapped glasses daily (loss ¥6,000).

(2). Polarization Camera Method: Automated glare removal inspection, 2 seconds/glass, detects 0.1mm bubbles, missed rate reduced to 0.3%, daily scrap reduced to 6 glasses (loss ¥180), annual savings >¥2 million, efficiency increased 15x.

• Suitable Scenarios: Internal bubble, impurity, crack inspection in phone glass, PV glass, optical lenses, plastic transparent containers, semi-transparent films.

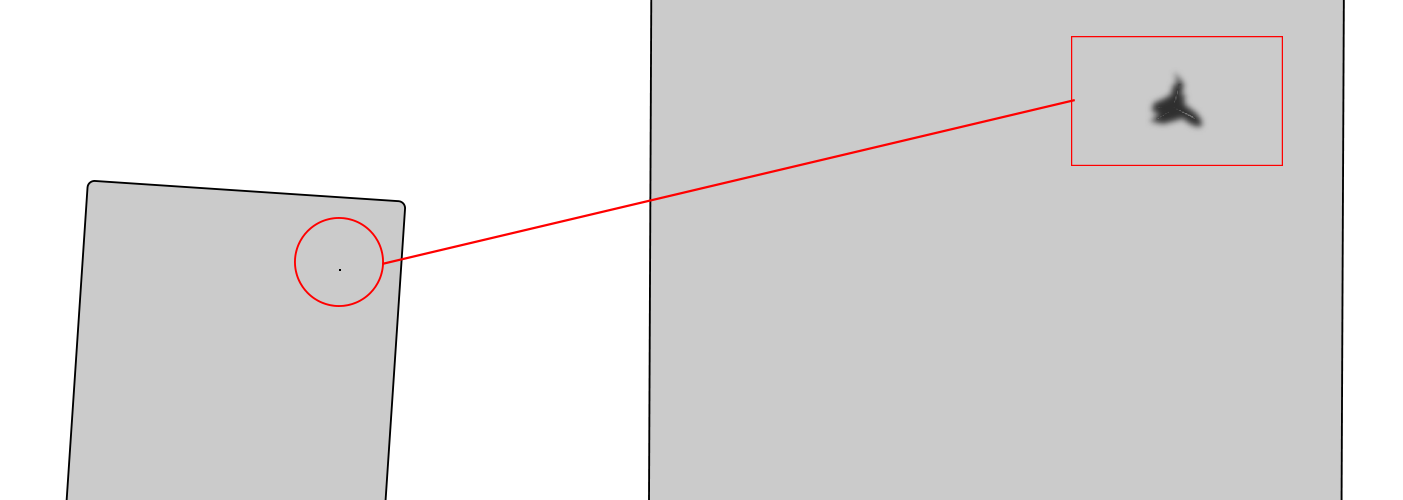

3. Scenario 3: Plastic/Composite Material Stress Inspection – Revealing Hidden Internal Stress Marks/Texture

• Pain Point: Internal "stress marks" from molding/forming in plastic parts (e.g., appliance housings, automotive interiors) and composites (e.g., carbon fiber sheets) are invisible but weaken parts. Traditional inspection requires a "polarimeter" (dedicated, slow: 2 minutes/part), incompatible with line speed (e.g., 10 parts/minute), forcing sampling (e.g., 10%), risking batch defects.

• Polarization Camera Solution:

(1). Technical Principle: Stress marks cause "birefringence" (light splits into two perpendicularly polarized beams). The camera captures the phase difference, converting it into "colored fringes" (dense where stress is high), visualizing hidden stress marks without a dedicated polarimeter.

(2). Hardware Setup: Use a 2MP polarization camera (supports phase difference analysis) + high-brightness area light (ensures light penetrates thick plastic) + line sync trigger system (coordinates with molding machine).

• Implementation Effect:

Plastic washing machine housing stress mark inspection:

(1). Traditional Method: Polarimeter sampling, 2 minutes/housing, 10% sampling rate, previously led to batch cracking (loss ¥500,000).

(2). Polarization Camera Method: 100% full inspection, 5 seconds/housing, detects hidden stress marks 0.5mm wide, 99.8% detection rate for stress anomalies, eliminates batch defects, annual savings >¥800,000, efficiency increased 24x.

• Suitable Scenarios: Internal stress mark, texture unevenness inspection in plastic appliance housings, automotive plastic interiors, composite components, plastic pipes.

4. Scenario 4: Coating/Film Uniformity Inspection – Detecting Thickness Variation/Skipped Coating

• Pain Point: Coating uniformity on car paint, furniture coatings, industrial films affects appearance/performance. Conventional cameras only see color differences, not thickness variations (e.g., 0.01mm paint difference). Traditional methods use "coating thickness gauges" (contact, 10 seconds/point), unsuitable for large areas, very inefficient.

• Polarization Camera Solution:

(1). Technical Principle: Different coating thicknesses cause different "changes in polarization state" in transmitted light. Thicker areas change polarization more. Analyzing these differences converts thickness variation into "brightness gradients" (dark=thick, light=thin), visually showing uniformity issues contact-free.

(2). Hardware Setup: Use an 8MP polarization camera (with polarization state analysis algorithms) + bar light (covers large area) + robotic arm (for 360° inspection).

• Implementation Effect:

Automotive paint uniformity inspection (requirement: 80±5μm):

(1). Traditional Method: Coating gauge sampling (10 points/car), 10 minutes/car, 12% missed rate (unevenness in unmeasured areas), 8% rework rate.

(2). Polarization Camera Method: Full inspection in 5 minutes/car, detects ±3μm thickness variation, 99.5% detection rate for uniformity issues, rework rate reduced to 0.5%, annual rework savings >¥1.2 million, efficiency increased 2x.

• Suitable Scenarios: Coating uniformity, skipped coating, thickness variation inspection for automotive paint, furniture coatings, industrial films, metal anti-rust coatings.

III. Pitfalls to Avoid: 3 Key Considerations

• Select Polarization Mode Based on Defect Type: Not all scenarios use the same mode. Cameras can be linear polarization (best for surface reflections on metal/glass) or circular polarization (better for curved/irregular surfaces like plastic curves, arched glass). Choosing wrong reduces effectiveness.

•Synchronize Light Source and Polarizer Angle: Essential for effect. Use unpolarized light sources (standard LEDs) and adjust the angle between light source and camera polarizer (best when perpendicular). Using polarized lights or wrong angles fails to eliminate glare.

• Consider Resolution & Frame Rate for Production Pace:

(1). Fine defects (e.g., 0.1mm scratch): Choose ≥5MP camera.

(2). High-speed lines (e.g., 1 glass/2 seconds): Choose ≥60fps camera.

(3). Large areas (e.g., car body): Choose area scan polarization camera to avoid stitching errors from line scan cameras.

IV. Summary: Polarization Cameras – Enabling Industrial Inspection to "Eliminate Glare and See Hidden Defects"

As industrial manufacturing demands higher defect detection accuracy and productivity, the limitations of conventional cameras – "glare interference and inability to see hidden defects" – become increasingly apparent.

Polarization cameras, with their unique capabilities of "glare elimination and revealing hidden features," are becoming essential tools in metalworking, transparent part manufacturing, plastic molding, coating, and other fields. They don't replace conventional cameras but fill the gap for "glare-prone scenarios and hidden defect detection," moving industrial vision inspection from "relying on luck and angles" to "stable and precise identification."