Applications of Ultraviolet and Infrared Light in Machine Vision Lighting

Machine vision systems are vital in modern industrial automation, quality inspection, and research, with lighting being a core component. While visible light is common, ultraviolet (UV) light and infrared (IR) light offer unique advantages where visible light falls short. This article explores their characteristics, key applications, and future trends in machine vision.

1. Overview of UV and IR Light in Machine Vision

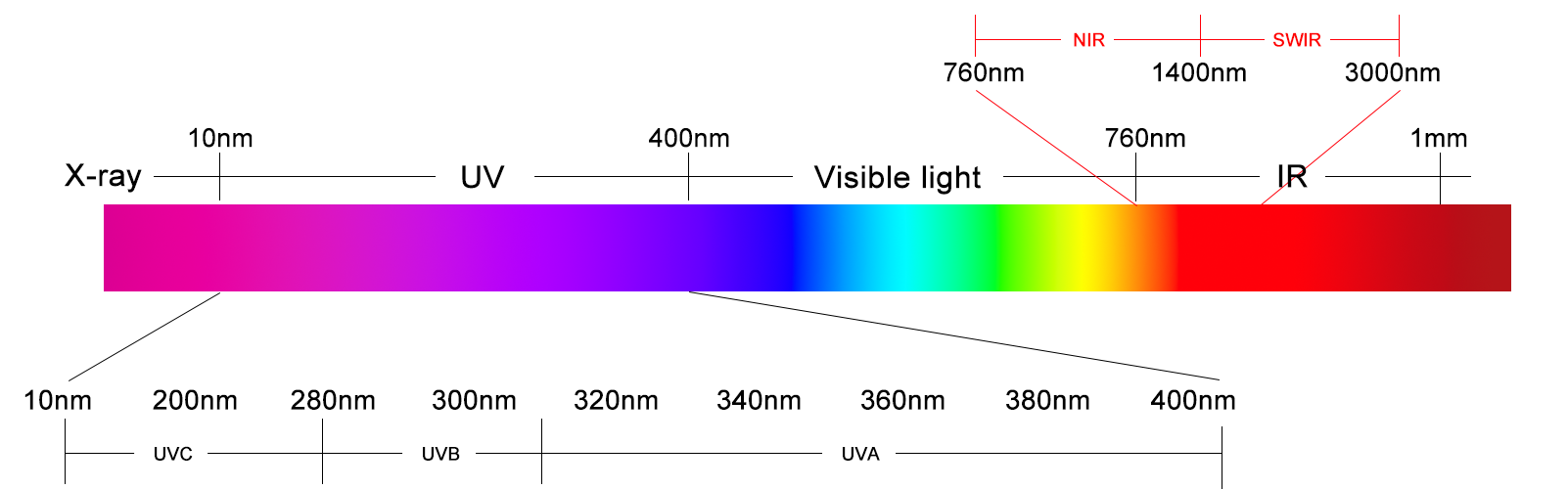

The electromagnetic spectrum’s visible range (400–760 nm) is detectable by the human eye, but UV (10–400 nm) and IR (760 nm–1 mm) extend machine vision capabilities. In practice, near-ultraviolet (UV-A, 315–400 nm) is preferred for safety and sensor compatibility, while near-infrared (NIR, 760–1400 nm) and short-wavelength infrared (SWIR, 1400–3000 nm) are common for IR tasks—they work with modified standard sensors and penetrate materials effectively.

UV excites fluorescence in specific substances, while IR interacts with materials based on chemical composition (absorption/transmission). These unique interactions drive their machine vision uses.

2. Applications of UV Light Sources

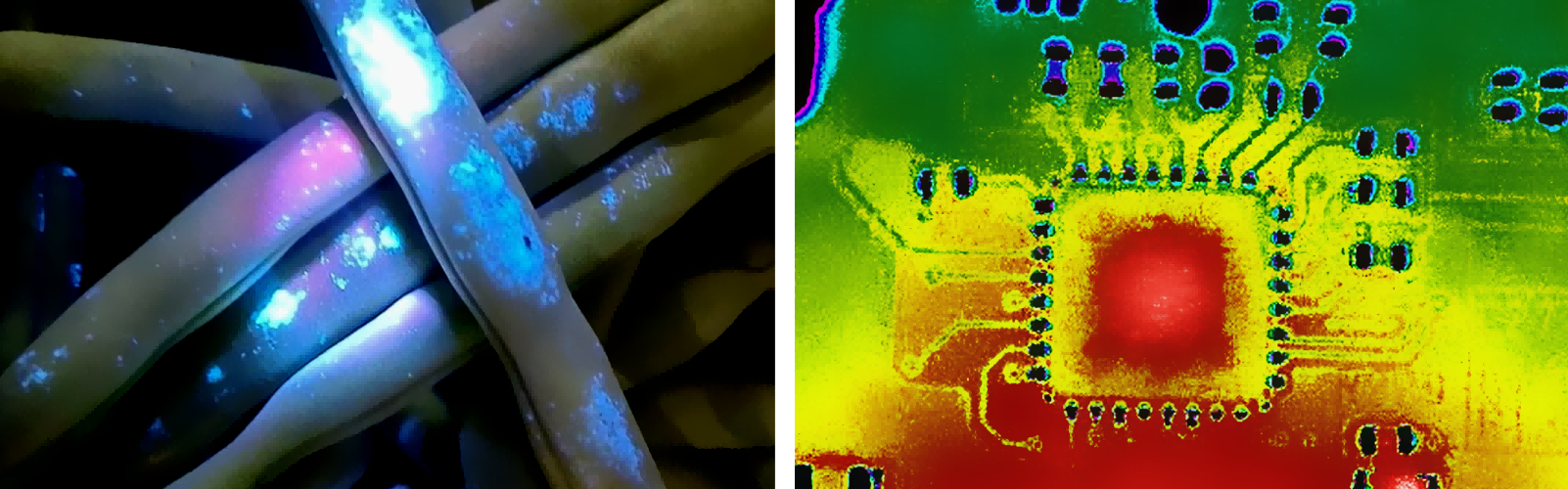

UV lighting leverages fluorescence and material contrast to detect invisible defects, contaminants, or features.

2.1 Industrial Quality Inspection

UV is widely used in quality control for surface defects and product integrity. For polymers (e.g., automotive plastic parts) and coatings (e.g., appliance paint), UV illuminates fluorescent additives—defects like cracks or pinholes create dark, non-fluorescent spots, which systems flag. In food/pharmaceuticals, UV identifies organic contaminants (mold, bacteria) and verifies tablet coating uniformity, as organic substances fluoresce against non-fluorescent materials.

2.2 Authentication and Anti-Counterfeiting

UV reveals hidden security features in documents (passports) and currency (Euro/US Dollar fluorescent threads). High-end products (luxury goods, electronics) use UV-marked labels; machine vision scans these under UV light to confirm authenticity, supporting supply chain anti-counterfeiting.

3. Applications of IR Light Sources

IR excels at material penetration, thermal contrast enhancement, and glare reduction, ideal for blocked or low-light scenarios.

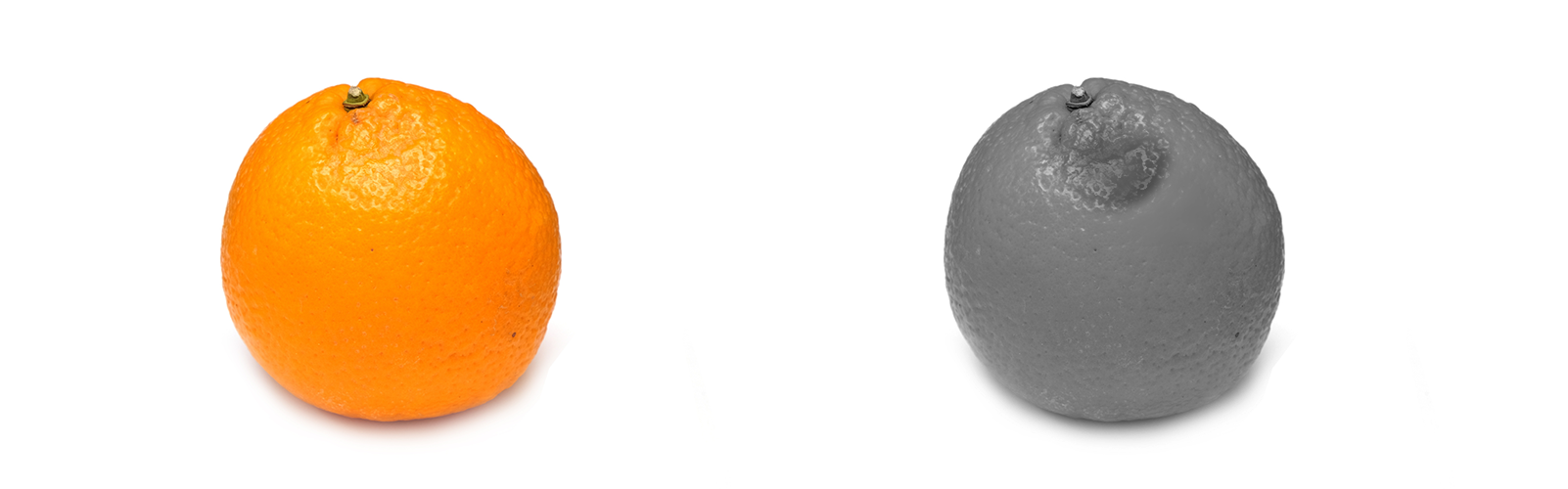

3.1 Material Penetration and Hidden Feature Detection

NIR/SWIR penetrates opaque materials. In semiconductors, it inspects IC/PCB internal connections (solder joints, defects) that visible light can’t reach. In agriculture, NIR reveals fruit internal defects (bruising) and measures grain moisture via absorption, optimizing sorting and storage.

3.2 Thermal Imaging and Temperature Measurement

IR captures thermal radiation for non-contact temperature monitoring. In manufacturing (metal casting, welding), thermal maps detect overheating/cold spots to ensure quality. In healthcare, IR measures skin temperature (fever detection) and tracks wound healing via blood flow changes; it’s also used in veterinary medicine for non-invasive injury detection.

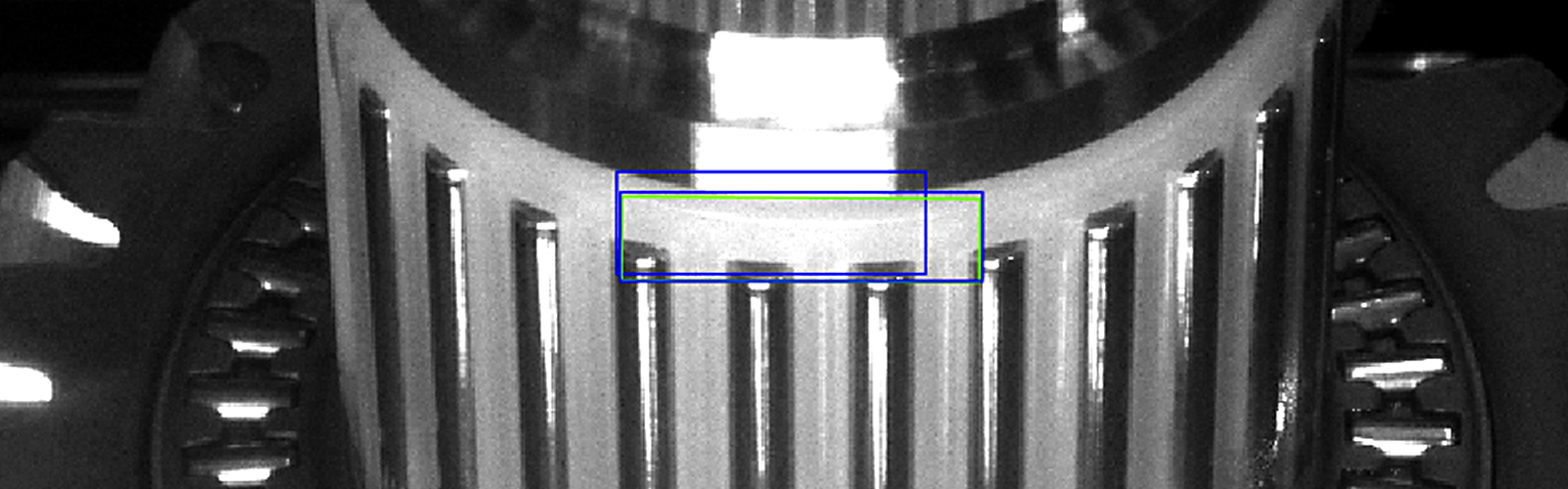

3.3 Glare Reduction and Low-Light Imaging

IR avoids glare from reflective surfaces (metal, glass) and works in darkness. For outdoor surveillance (traffic, logistics yards) or reflective material inspection (stainless steel appliances), IR eliminates glare and captures clear images, revealing scratches or dents hidden by visible light.

4. Key Differences Between UV and IR Light Sources

UV relies on fluorescence/contrast to detect hidden features/contaminants, requiring UV-sensitive cameras; UV-A is safe in low doses, but UV-B/C harms skin/eyes. IR uses penetration/thermal emission for opaque material inspection or thermal monitoring; most NIR works with standard sensors (SWIR needs specialized ones), and NIR is generally safe (high-power IR causes overheating). Choosing depends on the task—e.g., UV for food contaminants, IR for PCB internal checks.

5. Future Trends and Developments

UV/IR technology is advancing toward miniaturization (compact LEDs for portable systems), multispectral imaging (combining UV/visible/IR for comprehensive analysis, e.g., food quality profiling), and AI integration (algorithms improve defect detection accuracy and real-time decision-making).

6. Conclusion

UV and IR transform machine vision by enabling visible light-impossible tasks. UV excels at hidden defect/contaminant detection and authentication; IR offers penetration, thermal imaging, and glare reduction. As industries demand higher accuracy, their role will grow—understanding their properties helps businesses enhance quality, security, and efficiency.

HIFLY has over 15 years of manufacturing experience in the field of machine vision lighting. It has a professional R&D team. If you have any customized requirements for infrared or ultraviolet light, please feel free to contact us at any time!