إضاءة رؤية الآلة: ضمان الإضاءة الموحدة لالتقاط صور دقيقة

إضاءة رؤية الآلة: كيف تتحول الإضاءة المتجانسة إلى دقة فحص صناعي

لماذا تعتبر الإضاءة المتجانسة أمرًا لا محيد عنه في رؤية الآلة في الفحوصات الصناعية ذات المخاطر العالية، قد تؤدي الإضاءة غير المتسقة إلى إضعاف حتى أنظمة الرؤية الأكثر تقدمًا. يمكن أن يؤدي اختلاف السطوع إلى إخفاء العيوب الحرجة - مثل الشقوق الدقيقة في شفرات التوربين أو الفراغات في اللحام على لوحات الدوائر المطبوعة - مما يؤدي إلى قبولات خاطئة مكلفة. تحل مشاكل الإضاءة لدى HIFLY من خلال تقديم >90٪ من التجانس عبر مجال الرؤية، مما يخلق أساس بصري مستقر للتصوير الدقيق.

استراتيجيات الإضاءة الخاصة بالصناعة

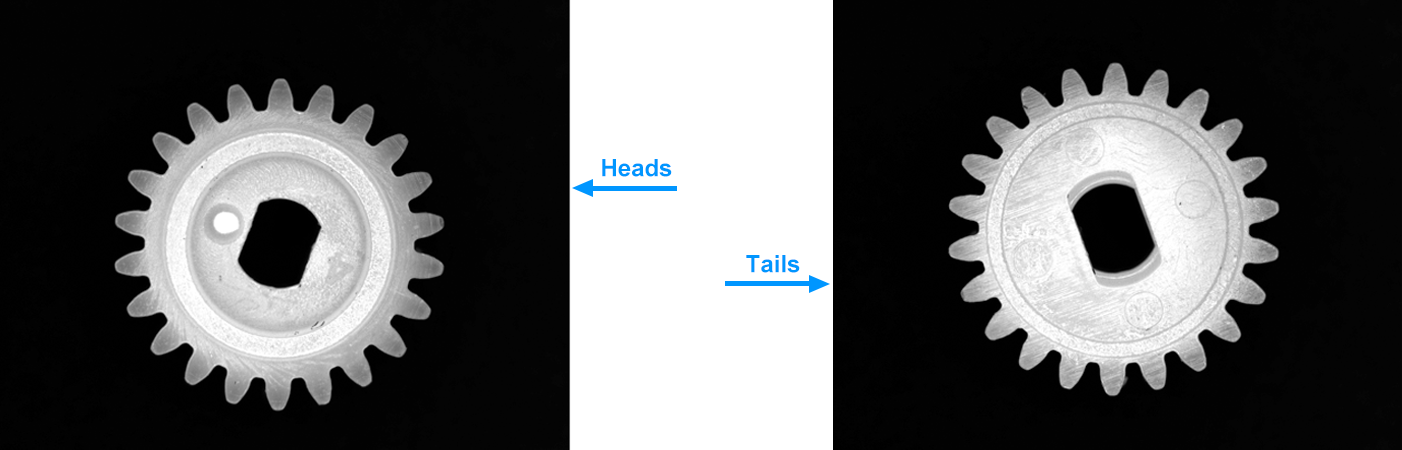

التغلب على الأسطح المرآتية في تجميع السيارات قد تُشتت المعادن عالية الانعكاس والمكونات المصقولة الضوء بشكل غير متوقع. في مهام مثل كشف الخدوش على أسطح التروس أو التحقق من الخيوط، قد تُخفف مصابيح الحلقة المستقطبة، المُزودة بموزعات زاوية قابلة للتعديل، من الوهج مع تحسين تباين العيوب. يضمن هذا النهج اتساق التصوير بغض النظر عن اتجاه القطعة.

قياس دقيق في تصنيع الإلكترونيات عند قياس المكونات بدقة الميكرون - من كرات اللحام BGA إلى أشرطة الدوائر المرنة - تثبت الإضاءة الخلفية المتلألئة أهميتها. الأشعة المتوازية الخاصة بها تقلل من تشوه الحواف، مما يمكّن من الدقة البعدية ضمن ±0.005mm. عند الجمع مع التحكم القابل للبرمجة في الشدة، تتكيف حلول HIFLY مع سمك المواد المختلفة دون إعادة الت head.

تحسين خطوط التغليف فائق السرعة على خطوط التعبئة التي تتحرك بسرعة 3 م/ث، قد يؤدي تشويش الحركة إلى تأثير سلبي على فحص إغلاق أو وضع العلامات. إن الإضاءة المتزامنة بدقة الميكروثانية مع مُشفِرات الناقل تجمد الحركة، بينما تتخلص المصفوفات الخطية متعددة القطاعات من الظلال على الحاويات المنحنية. النتيجة: تقليل التوقف غير المخطط له وزيادة OEE.

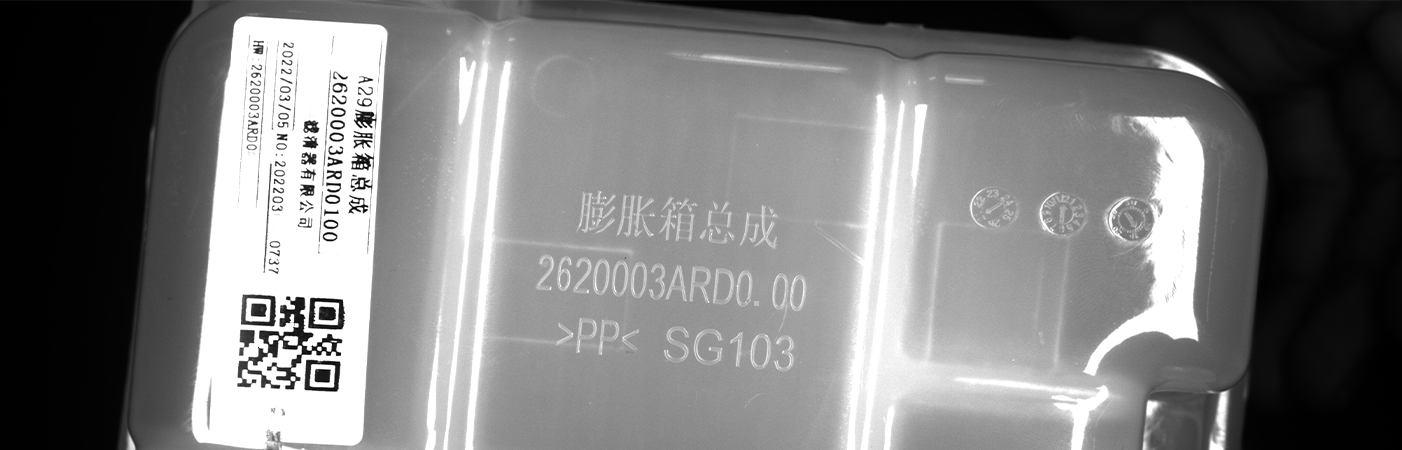

اعتمادية البيئة القاسية في البيئات مثل مراكز التصنيع باستخدام ضباب الزيت أو توجيه العربات ذاتية القيادة (AGV) في الهواء الطلق، يمكن أن تؤثر الإضاءة المحيطة بشكل خاطئ على القراءات. الإسكانات المصنفة حسب IP من HIFLY والمجهزة بتصفية الطيف (مثل تحسين IR/UV) تحافظ على قابلية قراءة OCR بنسبة >95٪ حتى في ظروف متغيرة، مما يقلل من الرفض الخاطئ. 54-المصنفة حسب الدرجة

تقنيات الإضاءة الجاهزة للمستقبل

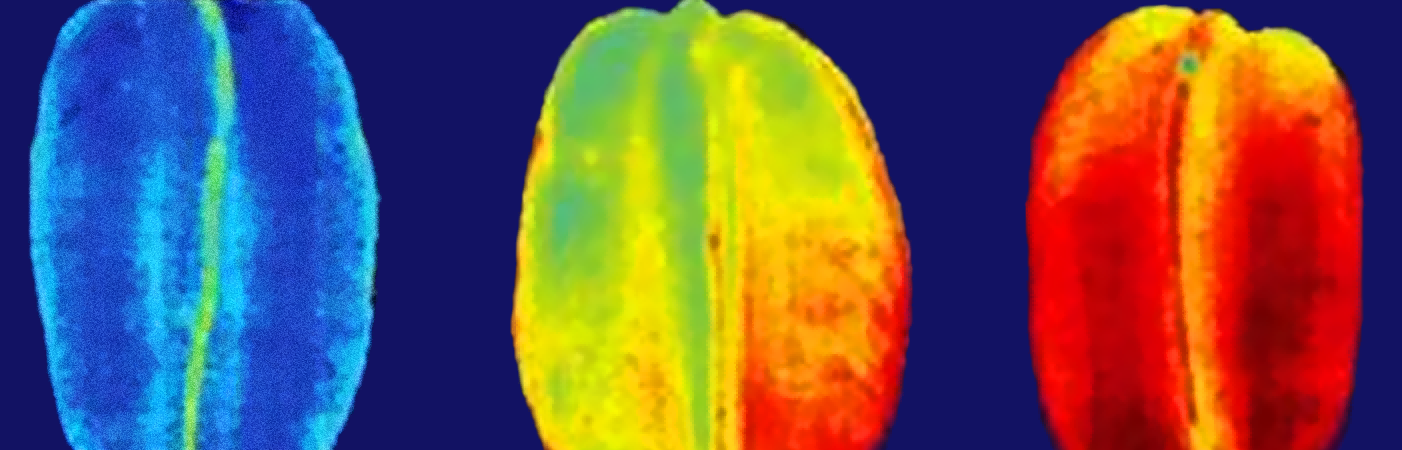

تكامل تصوير الطيف الفائق يمكن لأنظمة مصدر واحد تجمع بين الأطوال الموجية للأشعة فوق البنفسجية والمرئية والأشعة تحت الحمراء اكتشاف ملوثات غير مرئية في عبوات الأدوية أو تكوين المواد في تيارات إعادة التدوير - مهام مستحيلة تحت الإضاءة الأحادية اللون.

إضاءة متكيفة مدفوعة بالذكاء الاصطناعي تُعد المراقبات الذكية قادرة على ضبط الكثافة والزاوية الديناميكية بناءً على معدلات اكتشاف العيوب في الوقت الفعلي. يمكن أن يقلل هذا من متطلبات بيانات تدريب الخوارزمية بنسبة تزيد عن 30% مع تحسين التعرف على التشوهات في دفعات الإنتاج المتغيرة.

اختيار الإضاءة المثلى: الاعتبارات الرئيسية

عند تقييم الأنظمة، يجب على المهندسين التركيز على:

- تفاعل المادة السطحية : هل يتناثر الهدف، يمتص، أو يعكس الضوء؟

- الصلابة البيئية : هل يجب على النظام تعويض التغيرات في درجة الحرارة أو الجسيمات؟

- مرونة التكامل : هل يمكن للإضاءة التناسق مع وحدات التحكم المنطقية القابلة للبرمجة (PLCs) أو أنظمة تنفيذ الصناعة (MES) عبر OPC UA؟

تدعم محركات HIFLY القابلة للتخصيص والتصاميم الوحدية التعديلات السريعة في الحقل، مما يضمن توافقها مع بروتوكولات الفحص المتغيرة.

الخاتمة: الإضاءة كمحفز غير مرئي الإضاءة الموحدة تتخطى كونها 'مكونONENT'—إنها أساس موثوقية نظام الرؤية. من خلال القضاء على المتغيرات البصرية في البداية، يمكن للمصنعين تقليل 60٪ أو أكثر من الأخطاء المتعلقة بالتصوير، مما يحول عملية الفحص من مركز تكلفة إلى مصدر قيمة. تضمن حلول HIFLY الهندسية هذه الفلسفة، محولة الضوء إلى استخبارات صناعية قابلة للتنفيذ.