تطبيق مصادر الإضاءة الخطية الصناعية

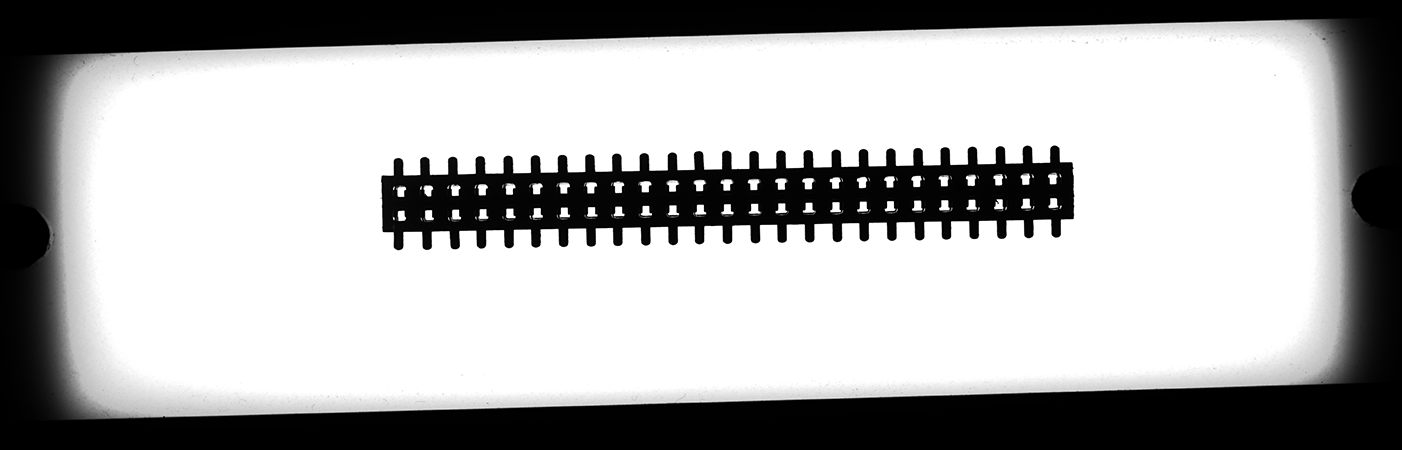

مصادر الإضاءة الخطية الصناعية هي نوع من معدات الإضاءة LED ذات الشكل الطويل والمستطيل. تتميز بسطوع عالٍ وتوحيد عالٍ وطول قابل للتخصيص وتركيب مرن، وتُستخدم على نطاق واسع في مجالات مثل الفحص الصناعي والرؤية الآلية. وتشمل مجالات التطبيق الرئيسية ما يلي:

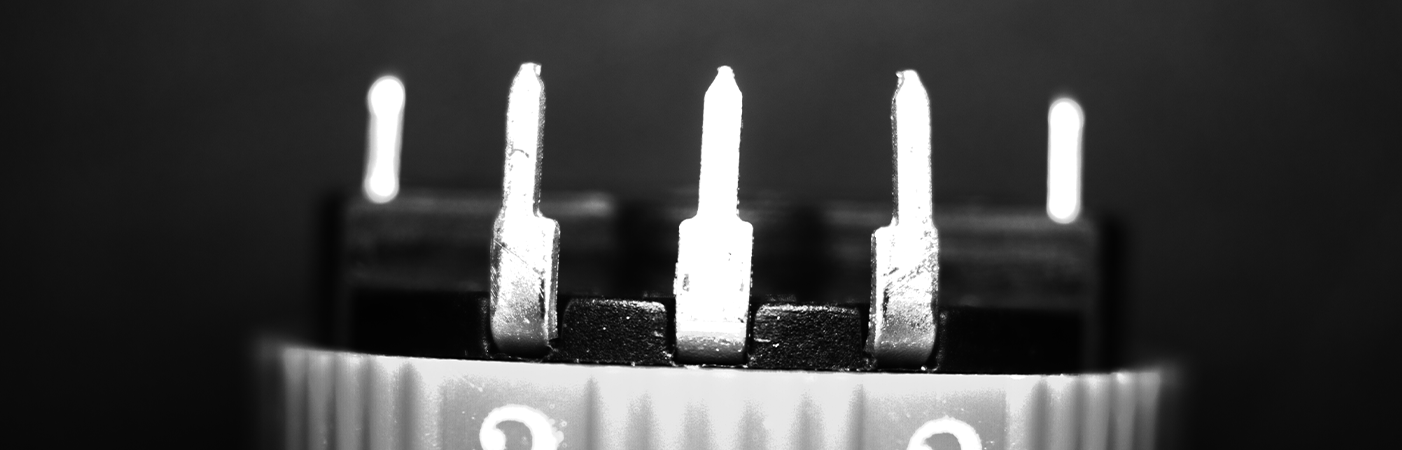

فحص العيوب السطحية

مناسبة للكشف عن العيوب السطحية (مثل الخدوش والطُّبَع والبقع والشقوق وما إلى ذلك) على مواد مثل المعادن والبلاستيك والزجاج والأفلام. يمكن لمصادر الإضاءة الخطية أن تُضيء من زوايا متعددة (على سبيل المثال، الإضاءة بزاوية منخفضة) لإنشاء تباين بين العيوب والسطح، مما يعزز من قابلية اكتشاف العيوب. وتُستخدم بشكل شائع في فحص جودة المكونات الإلكترونية وأجزاء السيارات ومواد التعبئة.

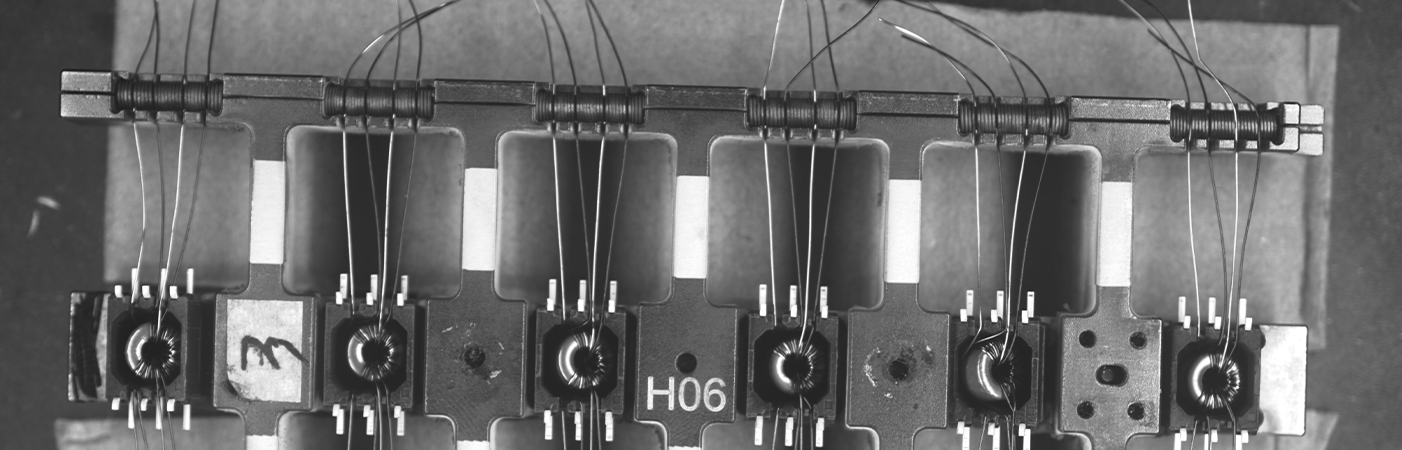

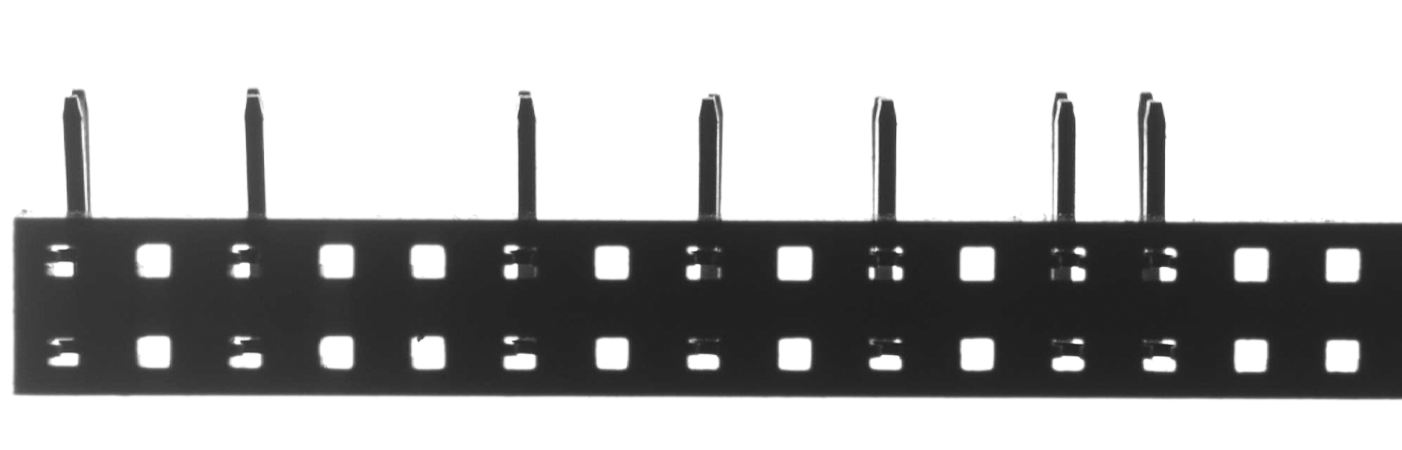

كشف الحواف والهياكل

باستخدام الخصائص الإضاءة الخطية لمصادر الضوء الشريطية، يمكنها إبراز الحواف أو الخطوط العريضة أو الفراغات بين الأشياء، مما يسهل على أنظمة الرؤية الآلية التعرف على شكل أو حجم أو موقع الأشياء. على سبيل المثال، تُستخدم في سيناريوهات مثل تحديد موقع لوحة الدوائر الكهربائية (PCB)، وقياس أبعاد القطع، وحساب العناصر على النواقل.

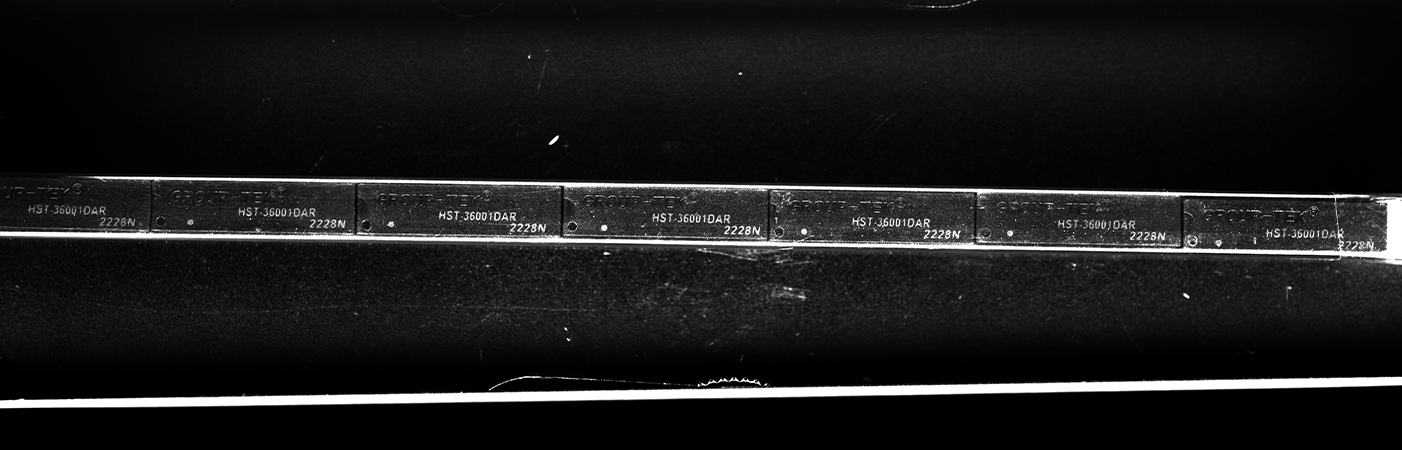

التعرف على الحروف والرموز الشريطية

بالنسبة للحروف المطبوعة على سطح المنتجات (على سبيل المثال، تواريخ الإنتاج، والأرقام الطرازية)، أو الرموز الاستثنائية (QR codes)، أو الرموز الشريطية (barcodes)، يمكن لمصادر الضوء الشريطية توفير إضاءة موحدة، وإزالة التداخل الناتج عن الانعكاسات أو الظلال، وضمان دقة التعرف على الحروف البصرية (OCR) أو مسح الرموز الشريطية. وتُستخدم بشكل واسع في تغليف الأغذية، والعلامات الإلكترونية، والتتبع اللوجستي، وروابط أخرى.

فحص خط التجميع عبر الإنترنت

يمكن تخصيص مصادر الإضاءة الخطية وفقًا لطول خط التجميع، مما يسمح بتكيفها مع مختلف سcenarios الإنتاج (مثل إنتاج الأفلام، ودرفلة الصفائح الفولاذية، ومعالجة الورق). وبالتعاون مع الكاميرات لالتقاط الصور في الوقت الفعلي، فإنها تحقق مراقبة جودة المنتجات المستمرة وإنتاجها عبر الإنترنت، واكتشاف أي تشاذيات بشكل فوري وتفعيل الإنذارات.

الإضاءة الخلفية

عند الحاجة إلى اكتشاف العيوب الداخلية أو الشوائب أو المحيط الخارجي للأجسام الشفافة أو شبه الشفافة (مثل الزجاج والأفلام والبلاستيك الأكريليكي)، يمكن استخدام مصادر الإضاءة الخطية كإضاءة خلفية. من خلال الضوء المنقول، تظهر تفاصيل الأجسام بشكل أكثر وضوحًا، وهو ما يُستخدم غالبًا في فحص شاشات ال سي دي، وفحص إغلاق أغطية الزجاجات وغيرها من العمليات.

باختصار، توفر مصادر الإضاءة الخطية الصناعية دعماً إضاءتياً مستقراً وموثوقاً لأنظمة الرؤية الآلية من خلال طرق تثبيت مرنة (مثل التوصيل المدمج والتعديل متعدد الزوايا) وأوضاع إضاءة مُعدة لتناسب مختلف السيناريوهات، مما يجعلها مكوناً أساسياً لا غنى عنه في الفحص الآلي الصناعي.