كيف تدعم المنشورات البصرية دقة الفحص الصناعي؟

في أنظمة الرؤية الصناعية للآلات، تمثل الكاميرا "العين"، والخوارزمية تمثل "الدماغ"، في حين يُعد المنشور البصري هو "قائد مسار الضوء" الخفي – غير مرئي وغير ملموس، ومع ذلك قادر على تمكين "العين" بدقة من التقاط الأهداف في البيئات الصناعية المعقدة من خلال انحراف الضوء وتعديل الصور وتوزيع حزم الضوء. سواء كان الأمر يتعلق بفحص الأجزاء في المساحات الضيقة، أو اكتشاف العيوب على سيور النقل السريعة، أو إجراء معايرة دقيقة في النمذجة ثلاثية الأبعاد، فإن المنشورات لا غنى عنها.

ⅰ. المهمة الأساسية للمنشورات: حل "تحديات مسار الضوء" في الرؤية الآلية

تُعد المواقع الصناعية أكثر تعقيدًا بكثير من المختبرات: فبعض نقاط الفحص مخفية بعمق داخل المعدات، مما يجعل المحاذاة المباشرة بالكاميرا مستحيلة؛ وبعض الأجزاء تتحرك بسرعات عالية، مما يتطلب التقاط تفاصيل متعددة الجوانب في آنٍ واحد؛ وبعض السيناريوهات تتطلب اتجاهًا دقيقًا جدًا للصورة، حيث تؤدي الانحرافات البسيطة إلى أخطاء في التقييم. وتكمن مهمة المنشورات (Prisms) في توفير حلول بصرية دقيقة مصممة خصيصًا لهذه "التحديات".

1. هل توجد قيود في المساحة؟ استخدم منشورًا لـ"ثني" الرؤية نحو الهدف

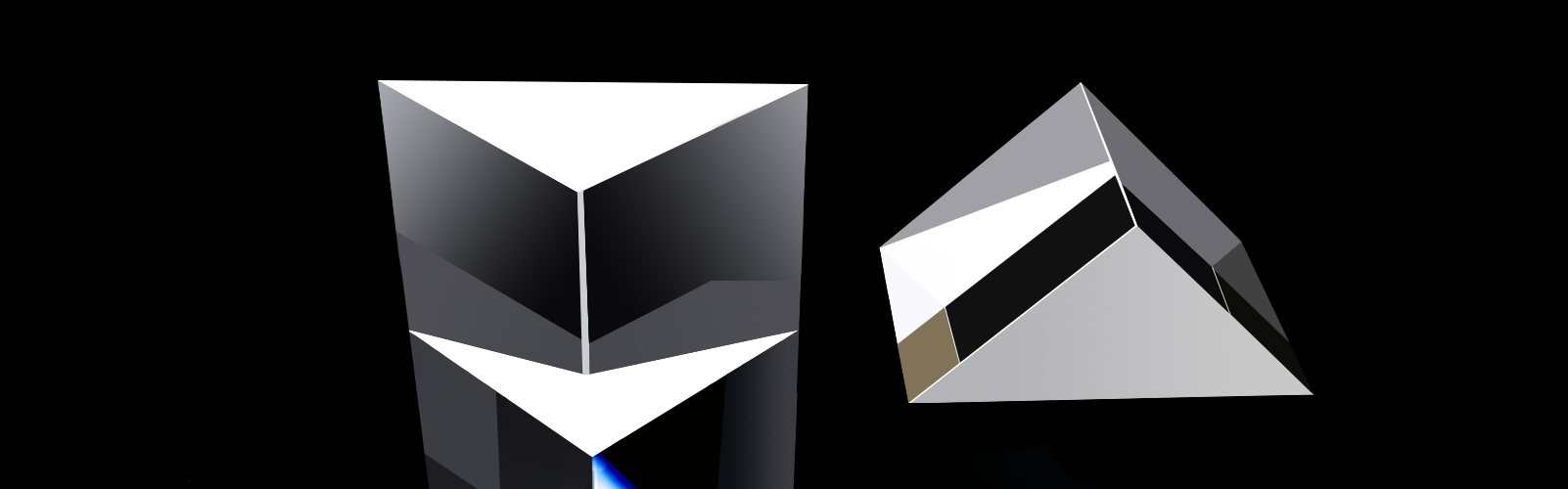

في فحص كتل محركات السيارات، تكون الممرات الهوائية الداخلية ضيقة ومعقدة، ولا يمكن لعدسات الكاميرا الدخول إليها للحصول على صور مباشرة. وهنا يُستخدم منشور الزاوية القائمة. ويشبه هذا المنشور "مرآة"، حيث يحرف الصورة من داخل الممر بزاوية 90 درجة، ويعكسها على مستشعر كاميرا خارجي — ما يعني إمداد الكاميرا بـ"عين منحنية" تمكنها من رؤية البنية الداخلية دون الحاجة إلى تفكيك الكتلة.

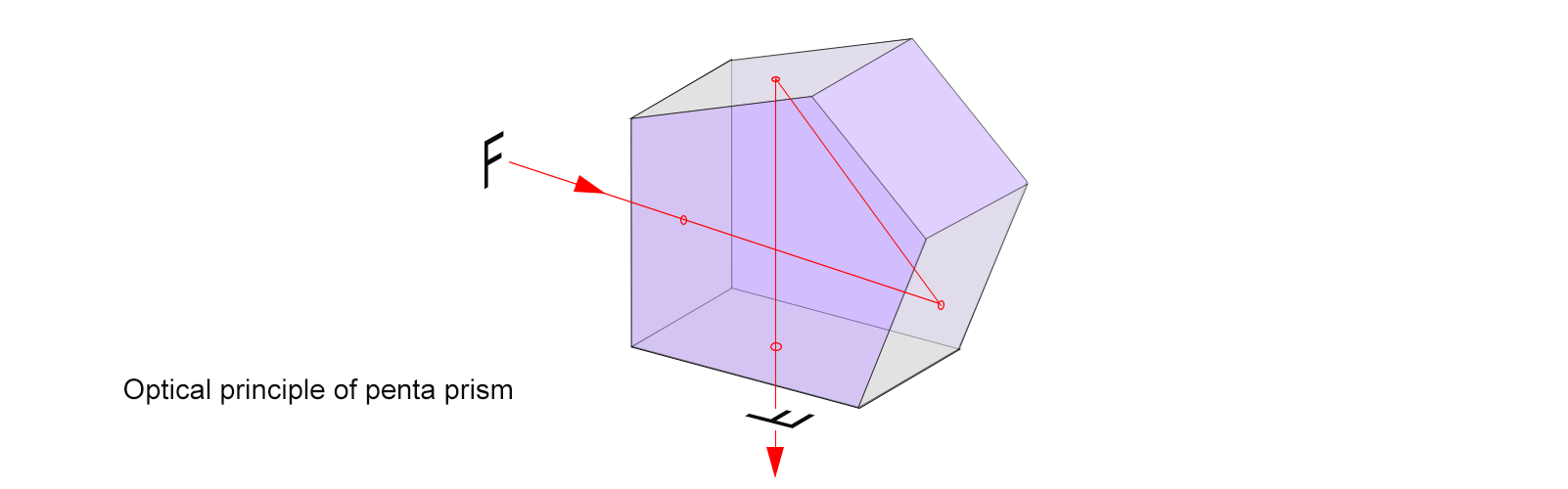

مكون متخصص أكثر، وهو المنشور الخماسي، يتمتع بالقدرة الفريدة على انحراف الضوء الوارد بدقة بمقدار 90 درجة بغض النظر عن زاوية الدخول. في أدوات قياس التروس عالية الدقة، يمكن أن يتحرك شعاع القياس بسهولة بسبب الاهتزازات أثناء الدوران عالي السرعة. يقوم المنشور الخماسي بثبيت وتصحيح مسار الضوء، مما يضمن التحكم في أخطاء القياس ضمن حدود 0.001 مم، والحفاظ على الدقة في فحص تباعد وتضاريس التروس.

2. مشاكل توجيه الصورة؟ استخدم منشورًا لـ"تصحيح" المنظور

الكاميرا في خطوط فرز الطرود، تكون الحزم مرتبة بشكل عشوائي — بعضها مستقيمة، وبعضها على جوانبها — مما يؤدي إلى توجهات صور فوضوية يصعب على الخوارزميات تفسيرها. هنا، يلعب المنشور السقفي دورًا رئيسيًا. فهو يقلب الصورة من اليسار إلى اليمين، ويقوم بإجراء "تصحيح مرآة" بحيث تكون صورة الملصق الملتقطة دائمًا في الوضع الصحيح، مما يزيد كفاءة الفرز بأكثر من 30٪.

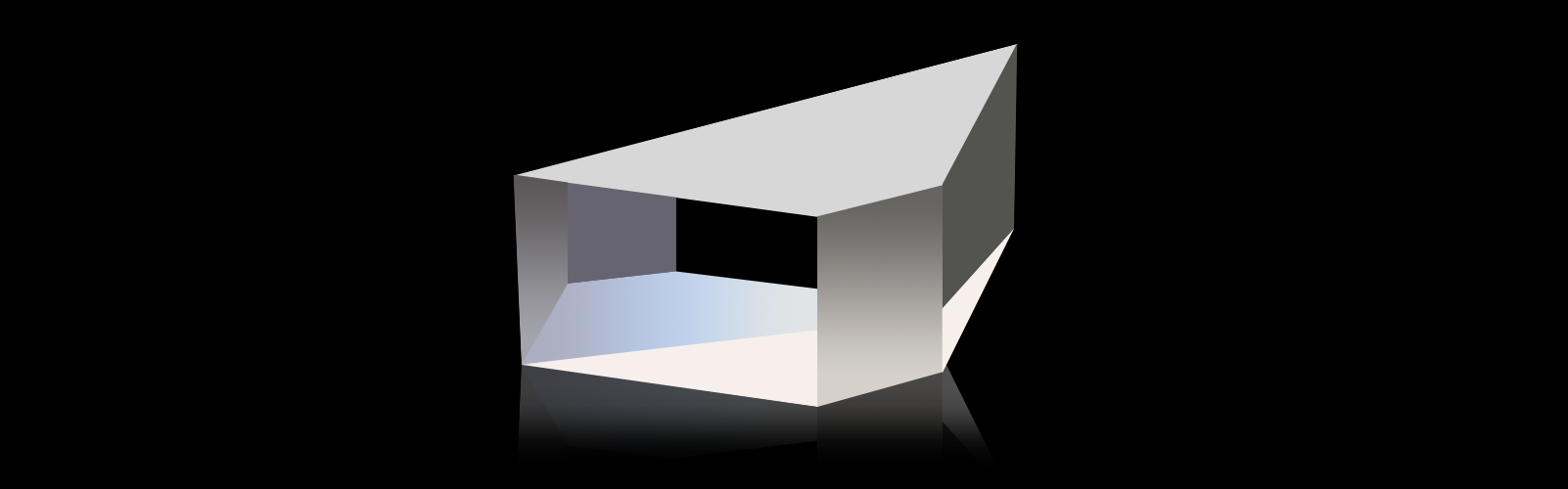

يُعد منشور دوف خبيرًا حقيقيًا في "تدوير الصورة"، حيث يمكنه تدوير الصورة بأي زاوية مرغوبة. في فحص دبابيس الشرائح، التي قد تنحرف بسبب سوء محاذاة الناقل، يقوم منشور دوف بتعديل زاوية الصورة في الوقت الفعلي، مما يسمح للخوارزميات بتحديد المسافات وسلامة كل دبوس بدقة، ويمنع الأخطاء الناتجة عن الانحراف الزاوي.

3. هل تحتاج إلى فحص متعدد الزوايا؟ استخدم منشورًا لـ"تقسيم" الشعاع لتحقيق التقاط متزامن

لإ Inspection أغطية الزجاج الخاصة بالهواتف المحمولة، يجب عرض العيوب الموجودة على الوجه الأمامي والجوانب والحافات في وقت واحد. إن استخدام كاميرات متعددة بشكل منفصل سيُعقّد التركيب وسيتطلب محاذاة الصور لاحقًا. ويحل هذا المشكل منشأر التوجيه المكعب. فهو يقسم مصدر ضوء واحد إلى شعاعين أو أكثر، ويعكسها إلى كاميرات بزوايا مختلفة—مما يحقق "مهام متعددة بشعاع ضوئي واحد". وهذا يقلل من عدد الكاميرات المطلوبة وتمكّن من التصوير المتزامن متعدد الزوايا، ما يضاعف كفاءة الفحص.

يؤدي المُعَاكِس الزاوي ثلاثي الأبعاد مهمة استثنائية تتمثل في عكس الضوء الوارد مباشرة على طول المسار الأصلي نفسه، تمامًا كأنه "مانع ارتداد الضوء". وفي ماسحات الليزر ثلاثية الأبعاد، يعمل منشور الزاوية الثلاثية مع أشعة الليزر لقياس اختلافات ارتفاع السطح بدقة من خلال انعكاسات متعددة، ما يسمح بإعادة بناء نموذج ثلاثي الأبعاد لهيكل هاتف بدقة تصل إلى 0.01 مم، وهي دقة تفوق بكثير الطرق التقليدية.

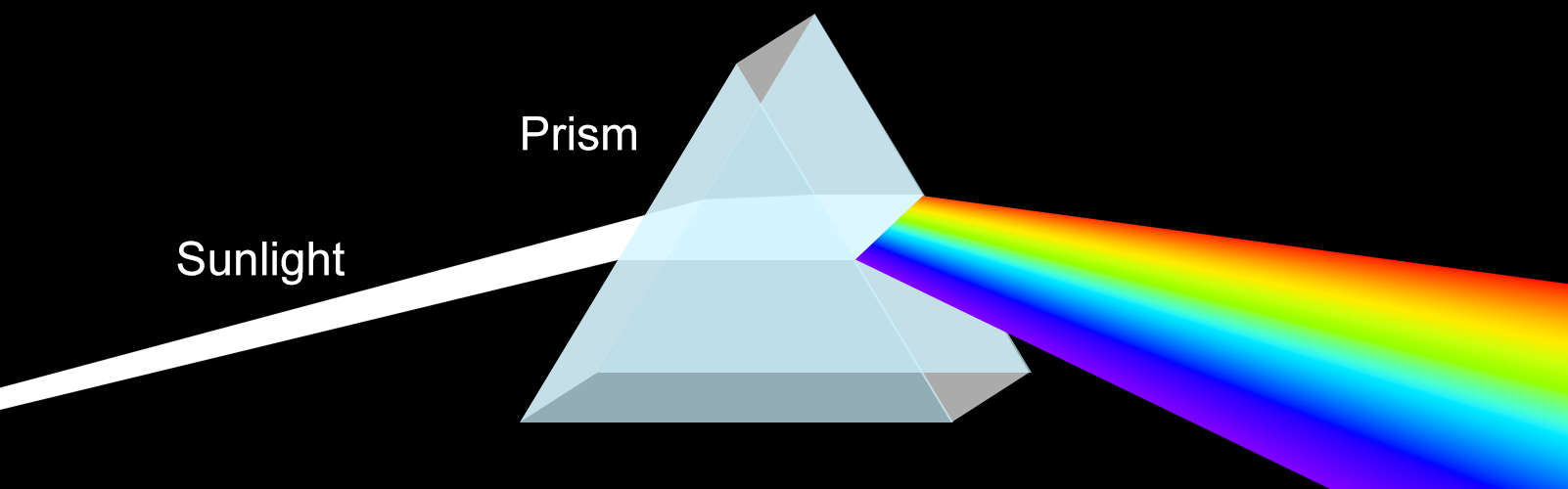

4. هل تحتاج إلى تحليل المواد؟ استخدم منشورًا لـ"تقسيم" الضوء

في فحص الأغذية، تحديد ما إذا كان مسحوق الحليب قد تم تزويره يتطلب تحليل خصائصه الطيفية. المنظار المثلث يعمل كـ "خبير في تفكيك الطيف". إنها تشتت الضوء الأبيض إلى أطوال موجة مختلفة أحمر، برتقال، أصفر، أخضر، أزرق، أحمر، بنفسجي. المواد المختلفة تمتص أطوال موجة محددة؛ من خلال تحليل طيف الامتصاص، يمكن الكشف عن وجود المواد المضافة غير القانونية في مسحوق الحليب، مما يوفر بديلا أسرع وأكثر ملاءمة للبيئة للاختبارات الكيميائية التقليدية.

ⅱ. تطبيقات العالم الحقيقي: كيف تتكيف المنشورات مع الاحتياجات الصناعية المتنوعة

وظائف رؤية الآلة المختلفة لديها متطلبات مختلفة جداً للأسحاف. اختيار نوع المنظر المناسب أمر حاسم لتحقيق أقصى قدر من أداء النظام. وهنا أربعة سيناريوهات تطبيق نموذجية:

1. تصنيف الحزام النقل: الزاوية اليمنى + مصارعة السقف تحل "لا أستطيع أن أرى، لا أستطيع أن أرى بوضوح"

على خط فرز زجاجات المياه، يتطلب التحقق من تطبيق الملصقات بشكل صحيح وإغلاق الأغطية بإحكام استخدام كاميرا تفتيش في موضع ثابت. ومع ذلك، فإن المساحة بجانب الناقل محدودة. يقوم منشور زاوي قائم أولاً بتحريف مسار الضوء بزاوية 90°، مما يسمح لكاميرا مثبتة جانبيًا برؤية جسم الزجاجة. وإذا تسبب انحراف الزجاجة في تقليب صورة الملصق، يقوم منشور سقفي بتصحيحه، ويضمن بذلك قراءة الخوارزمية الدقيقة لموقع الملصق وحالة الغطاء، ما يرفع معدل نجاح الفرز من 95% إلى 99.8%.

2. نمذجة الأجزاء ثلاثية الأبعاد: منشورات البنتا + المكعب تُنشئ "رؤية مجسمة"

عند فحص أقطاب بطاريات المركبات الكهربائية الجديدة، فإن قياس السُمك والمسطحية وملف الحافة يتطلب معلومات ثلاثية الأبعاد غير متوفرة من خلال رؤية واحدة فقط. هنا، يستخدم المنشور الخُماسي لاستقرار مسار الضوء، مما يمنع انحراف الشعاع، في حين يقوم منشوري مكعب بتقسيم الشعاع وإسقاطه على كamerات علوية وسفلية. وبحساب الفرق في الطور بين الشعاعين، يتم توليد نموذج ثلاثي الأبعاد للقطب بسرعة، مع خطأ في قياس السُمك لا يتجاوز 0.005 مم، وبالتالي الوقاية من مخاطر السلامة المحتملة الناتجة عن عدم انتظام سُمك القطب.

3. فحص سريع للسطح: منشور دوف يلتقط العيوب العابرة

في خطوط إنتاج تدحرج الصفائح الفولاذية، تتحرك الصفائح بسرعة 3 أمتار في الثانية، وتكون الخدوش أو التعرجات السطحية عابرة. لا يمكن لكاميرا واحدة تغطية العرض الكامل. يقوم منشور الحمامة (Dove prism) بتوسيع مجال رؤية الكاميرا إلى 120° من خلال تعديل زاوية الصورة. عند دمجه مع كاميرا عالية السرعة، فإنه يلتقط صورة للوجه الأمامي والطرفين في لحظة واحدة، ويكتشف أكثر من 1000 نقطة عيب في الثانية، مما يقلل التكاليف بنسبة 40٪ مقارنةً بالأنظمة التقليدية متعددة الكاميرات.

4. تحديد المواقع بالليزر: منشور الزاوية القائمة (Corner Cube Prism) يُمكّن من "الانعكاس الدقيق"

في لحام الروبوتات الصناعية، يكون تحديد موقع الشق بدقة أمرًا بالغ الأهمية، ويعتمد على أنظمة الليزر. يمكن أن تحرف اهتزازات ورشة العمل والغبار شعاع الليزر. يقوم منشور الزاوية القائمة المثبت على ذراع الروبوت بنهايته بعكس شعاع الليزر مباشرةً إلى مصدر الإرسال. ومن خلال حساب انحراف الضوء المنعكس، يتم تعديل موقع الروبوت في الوقت الفعلي، بحيث تتحكم دقة اللحام ضمن حدود 0.1 مم، مما يقلل بشكل كبير من معدلات العيوب.

ⅲ. اختيار مادة المنشور: ليس فقط "نقل جيد للضوء"، بل أيضًا "الصلابة"

تُعد البيئات الصناعية معقدة ومتغيرة؛ حيث يمكن أن تؤثر عوامل مثل درجات الحرارة العالية والرطوبة والاهتزاز والتآكل الكيميائي على أداء المنشور وعمره الافتراضي. لذلك، يتطلب اختيار المنشور مراعاة الأداء البصري إلى جانب متانة المادة. فيما يلي خمس مواد شائعة ومناطق استخدامها المناسبة:

|

نوع المادة |

الميزة الرئيسية |

السيناريوهات المناسبة |

الاحتياطات |

|

زجاج N-BK7 |

نفاذية عالية في نطاق الضوء المرئي وقريب الأشعة تحت الحمراء (≥92%)، وتكلفة منخفضة |

البيئات الصناعية القياسية، مثل فحص مظهر المكونات الإلكترونية، والقياسات البعدية |

غير مقاوم للحرارة (يتعرض للتشوه عند >100°م)، وغير مناسب للتطبيقات التي تستخدم الأشعة فوق البنفسجية |

|

السيليكا المصهورة للأشعة فوق البنفسجية |

ينقل الضوء فوق البنفسجي (200-400 نانومتر)، ومعامل تمدد حراري منخفض |

فحص الأشعة فوق البنفسجية (مثل فحص تصلب لوحات الدوائر المطبوعة بالأشعة فوق البنفسجية)، والقياسات الدقيقة |

التكلفة تعادل تقريبًا ثلاثة أضعاف تكلفة N-BK7، وسطح المادة يخدش بسهولة |

|

فلوريد الكالسيوم (CaF₂) |

تشتت منخفض، انتقالية عالية من الأشعة فوق البنفسجية إلى الأشعة تحت الحمراء |

التصوير متعدد الطيف (مثل تحليل تركيب الأغذية)، فحص الأشعة تحت الحمراء |

هش، مقاومة ضعيفة للتأثير، تجنب البيئات الاهتزازية |

|

الياقوت ز |

مقاومة عالية لدرجة الحرارة (نقطة انصهار 2050°م)، مقاوم للخدوش، مستقر كيميائيًا |

البيئات القاسية، مثل فحص أجزاء مصانع الصلب، فحص المحركات |

انتقالية أقل قليلاً مقارنةً بـ N-BK7، وتكلفة أعلى |

|

الجرمانيوم (Ge) / سيلينيد الزنك (ZnSe) |

انتقالية عالية في الأشعة تحت الحمراء (≥70% في نطاق 8-14 مايكرومتر) |

التصوير الحراري (مثل مراقبة درجة حرارة المعدات)، وكشف العيوب بالأشعة تحت الحمراء |

معرض للأكسدة بفعل الرطوبة، ويحتاج إلى حماية بواسطة طلاء |

مثال: عند قياس درجة حرارة الصلب المنصهر في ورشة صناعة الصلب، تتجاوز درجات الحرارة المحيطة 500°م. وفي هذه الحالة، قد تذوب منشورات الزجاج N-BK7 القياسية، بينما يتحمل منشور الياقوت هذا الحرارة الشديدة. وعند دمجه مع كاميرا الأشعة تحت الحمراء، فإنه يتيح مراقبة التغيرات في درجة الحرارة بشكل فوري. أما في فحص التصوير فوق البنفسجي في صناعة أشباه الموصلات، فإن السيليكا المتحدة بالأشعة فوق البنفسجية هي الخيار المفضل، حيث تضمن انتقالًا فعالًا للأشعة فوق البنفسجية للتحقق بدقة من دقة الأنماط.

ⅳ. اختيار المنشور وتصميمه: 3 مبادئ رئيسية لتجنب الأخطاء

إن اختيار المنشور المناسب يعزز الدقة والاستقرار في نظام الرؤية الآلية؛ أما الاختيار الخاطئ فيؤدي إلى أخطاء تفتيش كبيرة وفشل متكرر. فيما يلي ثلاثة مبادئ أساسية للاختيار:

1. حدد النوع بناءً على "متطلبات المهمة"، ولا تتبع بشكل أعمى السعي نحو "عالي الجودة"

• لتحويل الضوء ببساطة في المساحات الضيقة، يكفي استخدام منشور زاوي قائم؛ ولا حاجة لمنشور البنتا المكلف.

• لفحص زوايا متعددة بشكل متزامن، يجب إعطاء الأولوية لمقسم الحزمة المكعب بدلاً من استخدام كاميرات متعددة ومنشورات قياسية.

• لتدوير الصورة أو تصحيحها، اختر بين منشور دوف أو منشور السقف حسب الزاوية المطلوبة للدوران، وتجنب التكرار الوظيفي.

2. اختر المادة بناءً على "الظروف البيئية"، مع تحقيق التوازن بين الأداء والتكلفة

• درجة حرارة الغرفة القياسية، والبيئات غير المسببة للتآكل: اختر زجاج N-BK7 لأفضل توازن بين التكلفة والأداء.

• البيئات شديدة الحرارة أو القاسية: اختر الياقوت أو السيليكا المتحدة بالأشعة فوق البنفسجية للحصول على المتانة.

• في حالات الأشعة تحت الحمراء أو فوق البنفسجية: اختر مواد الأشعة تحت الحمراء المناسبة (Ge، ZnSe) أو مواد الأشعة فوق البنفسجية (السيليكا المتحدة بالأشعة فوق البنفسجية)؛ وتجنب الزجاج القياسي.

3. ركّز على "الدقة في التصنيع" لتحسين الأداء الكلي

• إن طلاء المنشور أمر بالغ الأهمية: في الحالات التي تتطلب انعكاسًا عاليًا (مثل فحص المعادن)، اختر منشورات مطلية بطبقة مضادة للانعكاس لتقليل فقدان الانعكاس وتحسين وضوح الصورة.

• يجب أن تفي دقة التصنيع بالمعايير: يجب التحكم في خطأ زاوية المنشور ضمن ±30 ثانية قوسية (الثانية القوسية = 1/3600 من الدرجة)، وإلا سيحدث انحراف في مسار الضوء، مما يؤثر على دقة الفحص.

• توافق النظام: يجب أن يتناسب حجم المنشور وطريقة تركيبه مع الكاميرا والعدسة لمنع سوء المحاذاة الناتج عن أخطاء التركيب.

الخلاصة: صغير ولكن قوي، "حجر الزاوية للدقة" في رؤية الآلات

في أنظمة الرؤية الآلية، قد لا تكون المنشورات بارزة مثل الكاميرات أو الخوارزميات، لكنها تتولى بصمت المهمة الأساسية المتمثلة في "التحكم في مسار الضوء"—وذلك بحل تحديات مثل القيود المكانية، وفوضى الصورة، والفحص متعدد الزوايا، ما يدفع فحص القطاع الصناعي من مجرد "الرؤية" إلى "الرؤية بدقة وسرعة".

سواء في تصنيع السيارات، أو إنتاج الإلكترونيات، أو فحص الأغذية، أو قطاع الطاقة الجديدة، فإن اختيار نوع ومواد المنشور المناسب هو مفتاح تحسين أداء نظام الرؤية الآلية. ومع تطور الرؤية الآلية نحو دقة أعلى وسيناريوهات أكثر تعقيدًا، ستزداد أهمية المنشورات بشكل أكبر.