শিল্প ব্যাকলাইটসের প্রয়োগ

শিল্প ব্যাকলাইটগুলি মূলত মেশিন ভিশন ইনস্পেকশন সিস্টেমে ব্যবহৃত হয়। স্থিতিশীল এবং সমান আলো সরবরাহ করে, তারা সনাক্তকৃত বস্তু এবং পটভূমির মধ্যে তুলনা বাড়িয়ে তোলে, ক্যামেরাগুলিকে স্পষ্টভাবে বিস্তারিত ধরতে সাহায্য করে। এগুলি নিম্নলিখিত পরিস্থিতিতে ব্যাপকভাবে প্রয়োগ করা হয়:

ইলেকট্রনিক্স নির্মাণ

পিসিবি বোর্ড পরিদর্শন: সার্কিট ত্রুটি (শর্ট সার্কিট, ওপেন সার্কিট), সোল্ডার জয়েন্টের মান, উপাদানের ভুল অবস্থান ইত্যাদি শনাক্ত করা। সার্কিটের স্পষ্টতা বাড়ানোর জন্য সাধারণত সবুজ বা সাদা ব্যাকলাইট ব্যবহার করা হয়।

অর্ধপরিবাহী/চিপ পরিদর্শন: চিপ পিনের আকৃতির পরিবর্তন, আঁচড়, এবং প্যাকেজিং ত্রুটি সনাক্ত করা। প্রতিফলনের প্রভাব কমাতে রিং লাইট বা সহ-অক্ষীয় আলো ব্যবহার করা যেতে পারে।

ইলেকট্রনিক উপাদান পরিদর্শন: যেমন রেজিস্টর এবং ক্যাপাসিটরগুলির মাত্রা পরিমাপ এবং চেহারা ত্রুটি পরিদর্শন করা। এলাকা আলো সমতল পৃষ্ঠের পরিদর্শনের একরূপতা নিশ্চিত করে।

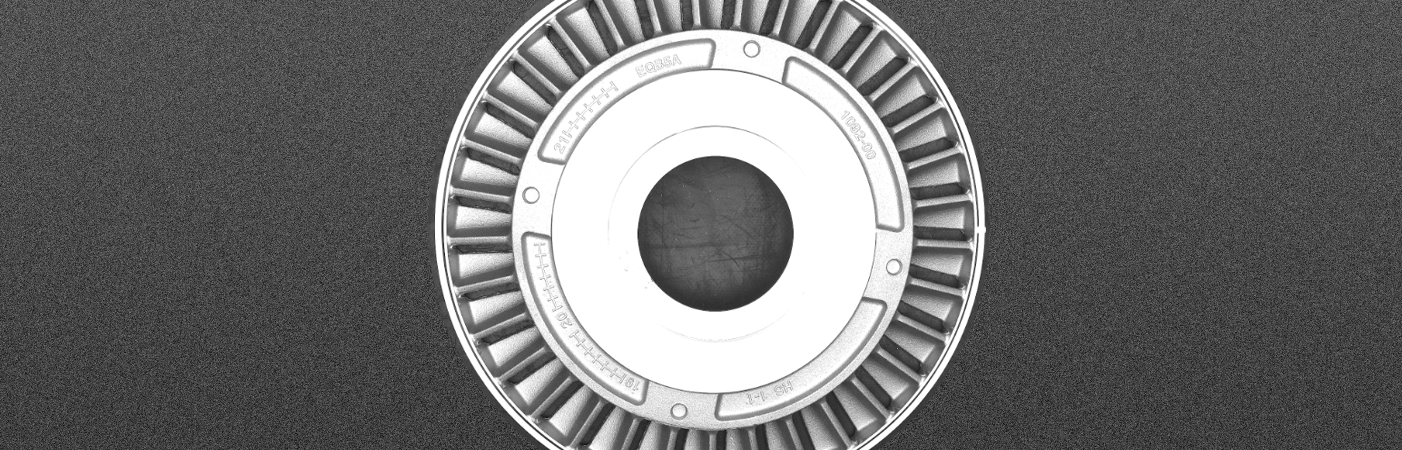

যান্ত্রিক অংশ পরিদর্শন

ধাতব অংশ: পৃষ্ঠের দাগ, উঁচু-নিচু এবং বার্ন শনাক্তকরণ। নীল বা অতিবেগুনী আলো ক্ষুদ্র ত্রুটিগুলি স্পষ্ট করে তোলে; মাত্রা এবং রূপরেখা পরিমাপের সময় লাইন লাইটস বা বার লাইটস লাইন স্ক্যান ক্যামেরার সংমিশ্রণ নির্ভুলতা উন্নত করে।

প্লাস্টিকের অংশ: ইনজেকশন ছাঁচন ত্রুটি (বুদবুদ, উপকরণ ঘাটতি) এবং রঙের বিচ্যুতি শনাক্তকরণ। বিভিন্ন উপকরণের আলোক স্থানান্তরের জন্য সাদা বা লাল আলো উপযুক্ত।

প্যাকেজিং এবং প্রিন্টিং শিল্প

প্যাকেজিং চেহারা পরিদর্শন: যেমন ঢাকনা এবং বোতলের ক্ষতি, দাগ এবং লেবেল মিসঅ্যালাইনমেন্ট। বৃত্তাকার বস্তু পরিদর্শনের জন্য আঙটি আলো উপযুক্ত।

মুদ্রিত পণ্য পরিদর্শন: মুদ্রিত নকশায় রঙের রেজিস্ট্রেশন বিচ্যুতি, অনুপস্থিত মুদ্রণ এবং ধোঁয়াশা পাঠ্য শনাক্তকরণ। বৃহৎ মুদ্রিত পণ্যগুলির সমবেত আলোকসজ্জা নিশ্চিত করতে এলাকা আলো প্রয়োজন।

খাদ্য এবং ওষুধ প্যাকেজিং

প্যাকেজিং অখণ্ডতা পরিদর্শন: যেমন পরীক্ষা করা যে অ্যালুমিনিয়াম ফয়েল সিলগুলি কি শক্তভাবে বন্ধ আছে এবং কাচের বোতলে বিদেশী বস্তু আছে কিনা। অবলোহিত আলো স্বচ্ছ প্যাকেজিংয়ের মধ্যে দিয়ে ভেতরের অবস্থা চিহ্নিত করতে পারে।

লেবেল পরিদর্শন: ওষুধ এবং খাদ্য লেবেলের লেখা স্পষ্টতা এবং বারকোড/কিউআর কোড চিহ্নিতকরণ পরীক্ষা করা। সাদা আলো রং এবং বিস্তারিত তথ্য সঠিকভাবে ধরা নিশ্চিত করে।

ফিল্ম এবং শীট পরিদর্শন

স্বচ্ছ উপকরণ: যেমন কাচ, ফিল্ম এবং প্লাস্টিকের শীটের গুণগত মান, আঁচড়, আবর্জনা এবং অসম পুরুতা। লাল বা অবলোহিত আলো অভ্যন্তরীণ ত্রুটিগুলি দৃশ্যমানতা বাড়ায়।

গুটিযুক্ত উপকরণ পরিদর্শন: কাপড়, কাগজ এবং ধাতব পাতের পৃষ্ঠের ত্রুটি (ছিদ্র, দাগ) সনাক্ত করা। লাইন আলো লাইন স্ক্যান ক্যামেরার সাথে সংযুক্ত হয়ে উচ্চ গতির নিরবিচ্ছিন্ন পরিদর্শন বাস্তবায়িত করে।

অটোমোবাইল উৎপাদন

উপাদান পরিদর্শনঃ যেমন টায়ারের ডিজাইন, ব্রেক প্যাড ক্ষয়, এবং তারের হার্নেস সংযোগকারী ত্রুটি। বার লাইটগুলি নির্দিষ্ট স্থানীয় বিবরণ আলোকিত করতে পারে।

অ্যাসেম্বলি পরিদর্শন: যাচাই করা হচ্ছে কিনা অংশগুলি সঠিকভাবে ইনস্টল করা হয়েছে (যেমন মিসিং স্ক্রু, স্ন্যাপ ক্লোজার)। এলাকার আলোগুলি অ্যাসেম্বলি এলাকার সামগ্রিক দৃশ্যমানতা নিশ্চিত করে।

সংক্ষেপে, শিল্প ব্যাকলাইটগুলির প্রধান কাজ হল মেশিন ভিশনে "স্পষ্টভাবে দেখা" সমস্যার সমাধান করা। বিভিন্ন পরিস্থিতিতে, সনাক্তকৃত বস্তুর উপকরণ, আকৃতি এবং পরীক্ষা লক্ষ্য অনুযায়ী উপযুক্ত আলোর ধরন এবং পরামিতি নির্বাচন করা প্রয়োজন।