কোন পরিস্থিতিতে সাধারণ মেশিন ভিশন লাইট সোর্স ব্যবহার করা যেতে পারে? স্মার্ট আলোকপাতের জন্য একটি গাইড

আলোকসজ্জা হল মেশিন ভিজনের অজানা নায়ক, একটি ভাল সিস্টেমকে একটি দুর্দান্ত সিস্টেমে পরিণত করে। সঠিক আলোর উৎস লুকানো ত্রুটিগুলি প্রকাশ করতে পারে, সমালোচনামূলক বৈশিষ্ট্যগুলিকে তুলে ধরতে পারে এবং আপনার স্বয়ংক্রিয় পরিদর্শনগুলি সুচারুভাবে চালিত হয় তা নিশ্চিত করতে পারে। কিন্তু এতগুলো বিকল্পের সাথে, যেমন রিং লাইট, ব্যাকলাইট, এবং গুম লাইট, সেগুলো কোথায় সবচেয়ে ভালোভাবে ফিট করে? আপনি সার্কিট বোর্ড পরিদর্শন করছেন বা পণ্যগুলি বাছাই করছেন, সাধারণ মেশিন ভিজন আলোর উত্সগুলি কীভাবে প্রয়োগ করবেন তা বোঝা আপনার উত্পাদন লাইনকে রূপান্তর করতে পারে।

এই ব্লগ পোস্টে, আমরা সবচেয়ে জনপ্রিয় আলোক উৎস এবং তারা কোথায় সবচেয়ে উজ্জ্বলভাবে জ্বলে তা খুঁজে পাওয়ার চেষ্টা করব। শিল্প থেকে খাদ্য প্রসেসিং পর্যন্ত, আমরা এটি সহজ ভাষায় ব্যাখ্যা করব যাতে আপনি নিশ্চিন্তে আপনার ভিশন সিস্টেমকে আলোকিত করতে পারেন। চলুন শুরু করি এবং দেখি এই আলো আপনাকে কোথায় নিয়ে যেতে পারে!

মেশিন ভিশনে আলোক কেন গুরুত্বপূর্ণ

মেশিন ভিশন সিস্টেম ক্যামেরার উপর নির্ভর করে যা বস্তু দেখতে হয়, কিন্তু ক্যামেরা শুধুমাত্র আলো যা প্রকাশ করে তা ধরতে পারে। একটি ভালোভাবে নির্বাচিত আলোক উৎস কন্ট্রাস্টকে বাড়িয়ে দেয়, চমকের কম করে এবং সীমা, টেক্সচার বা রঙ এমন বিস্তারিত বের করে। যে শিল্পে সূক্ষ্মতা সবকিছু, সেখানে আলোক আপনার সিস্টেমের জন্য ডিফেক্ট ধরতে, লেবেল যাচাই করতে বা অংশ মাপতে সাহায্য করে। প্রতিটি আলোক উৎস কোথায় প্রয়োগ করা উচিত তা জানা এই উপকারিতা খুলে তুলতে একমাত্র চাবিকাঠি।

আসুন তাহলে সাধারণ মেশিন ভিশন আলোকের কাজের সেরা সিনারিওগুলোতে নেমে যাই।

সাধারণ মেশিন ভিশন আলোক উৎস এবং তাদের প্রয়োগ

এখানে শীর্ষ আলোক উৎসগুলি এবং তারা যে বাস্তব জগতের সituationsয়ে উত্তমভাবে কাজ করে:

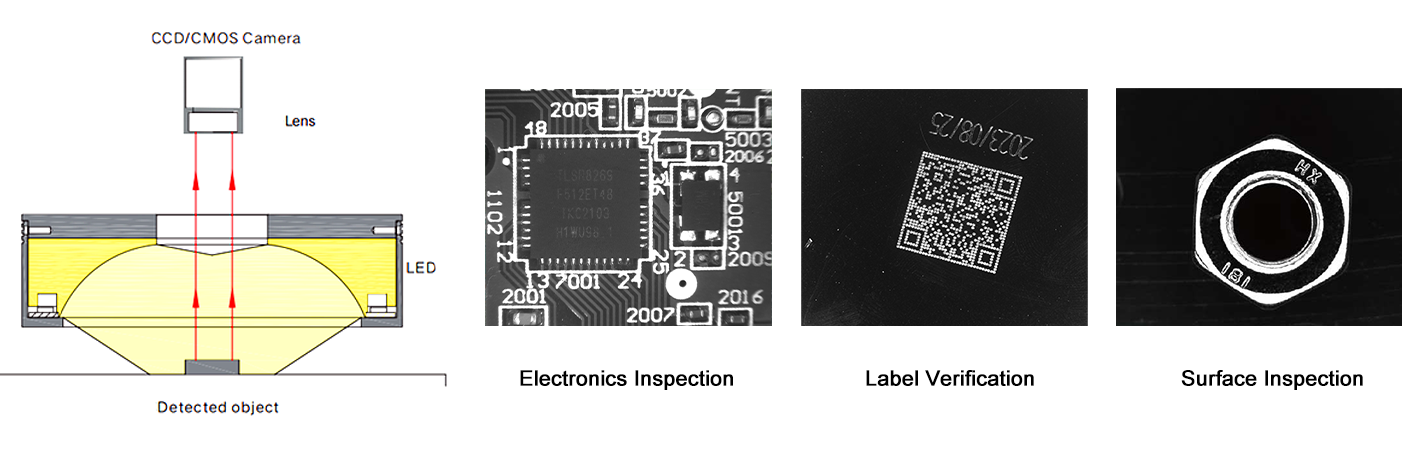

১. রিং লাইটস: সমগ্র প্রদীপ্তি

তারা কিভাবে কাজ করে: রিং লাইটস ক্যামেরা লেন্সের চারপাশে ঘিরে থাকে, যা সমস্ত দিক থেকে সমান এবং ছায়ামুক্ত আলো প্রদান করে।

শ্রেষ্ঠ সituationsয়ে:

ইলেকট্রনিক্স পরীক্ষা: সার্কিট বোর্ডে সোল্ডার জয়েন্ট বা খাড়ি পরীক্ষা করা—রিং লাইটস সূক্ষ্ম দোষ আবিষ্কারে একক আলোক প্রদান করে।

লেবেল যাচাইকরণ: প্যাকেজিং-এর ব্যারকোড বা লেবেল পড়া, যেখানে ছায়া বিবরণ গোপন করতে পারে।

পৃষ্ঠ পরীক্ষা: কাচ বা ধাতু শীটের মতো সমতল বস্তু পরীক্ষা করা ডিফেক্ট খুঁজতে।

এটি কেন কাজ করে: বৃত্তাকার ডিজাইন ছায়া হ্রাস করে এবং পৃষ্ঠের বিস্তারিত উল্লেখ করে, যা একটি সমতল বা আধা-সমতল বস্তুর জন্য প্রধান হয়।

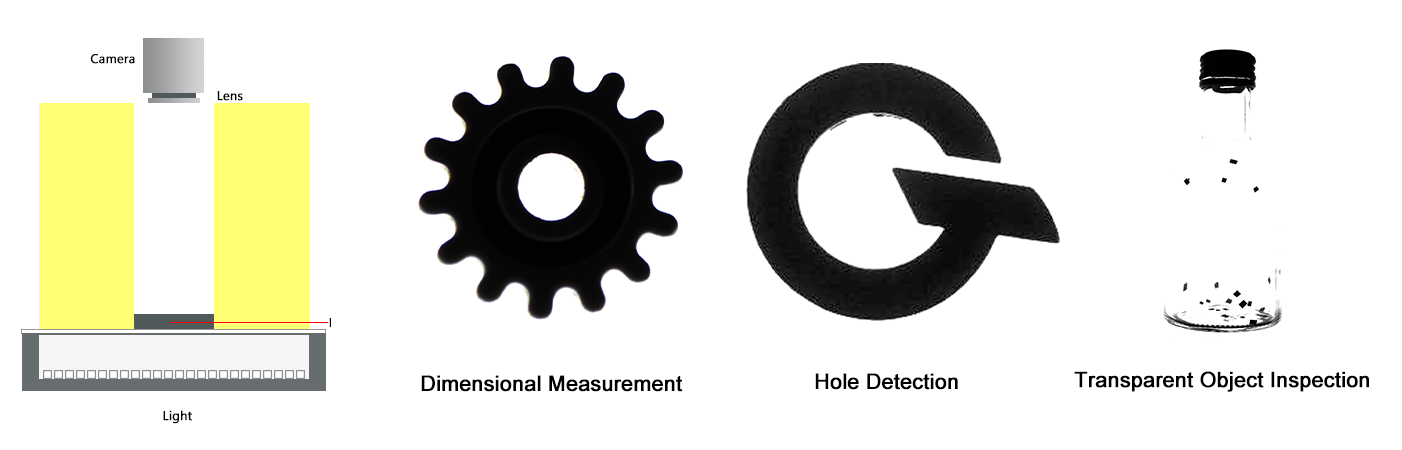

২. ব্যাকলাইটস: সিলুয়েট নির্ভুলতা

তারা কিভাবে কাজ করে: পিছনের আলো বস্তুর পিছনে থাকে, যা পটভূমি আলোকিত করে উচ্চ-তীব্রতা সহ একটি রূপরেখা তৈরি করে।

শ্রেষ্ঠ সituationsয়ে:

মাত্রা মাপ: ওয়াশার বা গিয়ারের মতো অংশের রূপরেখা মাপা হয় যেন তা নির্দিষ্ট প্রমাণ মেটাতে পারে।

ছিদ্র নির্দেশনা: প্লাস্টিক বা ধাতব উপাদানে অনুপস্থিত বা ভুল জায়গায় ছিদ্র খুঁজে পাওয়া।

ধারণীয় বস্তু পরীক্ষা: কাঁচের বোতলে ফাটল বা অপurity পরীক্ষা করা হয় তাদের ধার উজ্জ্বল করে।

এটি কেন কাজ করে: বস্তু এবং পটভূমির মধ্যে তীব্র তীব্রতা ধার বের করে, যা আকৃতির উপর ভিত্তি করে বিশ্লেষণের জন্য পারফেক্ট।

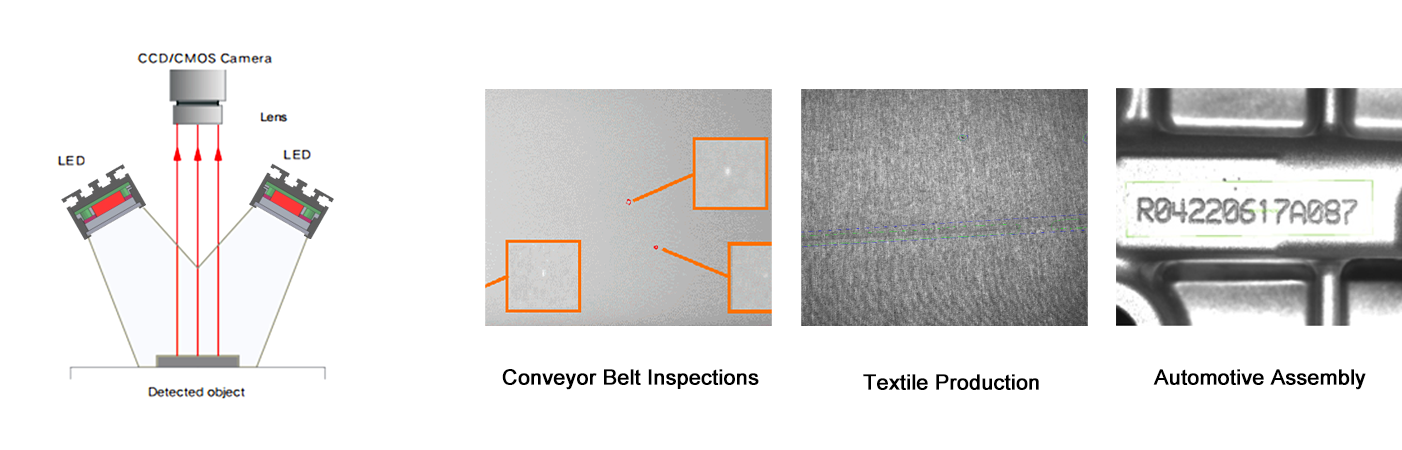

৩. বার আলো: বড় এবং রেখাচিত্র আবরণ

তারা কিভাবে কাজ করে: বার আলো দীর্ঘ এবং রেখাচিত্র উৎস যা বড় বা চলমান বস্তু আলোকিত করতে স্থাপন করা যেতে পারে।

শ্রেষ্ঠ সituationsয়ে:

ট্রান্সপোর্টার বেল্ট পরিদর্শন: কাগজের রোল বা লোহার শীটসমূহের মতো অবিচ্ছিন্ন উপাদানগুলির ত্রুটি খোঁজা।

টেক্সটাইল উৎপাদন: বড় এলাকায় কাপড়ের জালায় ফাটল বা বুননের অসঙ্গতি পরীক্ষা করা।

অটোমোবাইল আসেম্বলি: গাড়ির প্যানেলের মতো দীর্ঘ উপাদানগুলি পৃষ্ঠের পরীক্ষা জন্য উজ্জ্বল করা।

এটি কেন কাজ করে: তাদের লাইনার ডিজাইন লাইন-স্ক্যান ক্যামেরার সাথে পূর্ণ মিল রয়েছে, যা চওড়া ক্ষেত্রগুলি ঢাকে এবং তীব্রতা হারায় না।

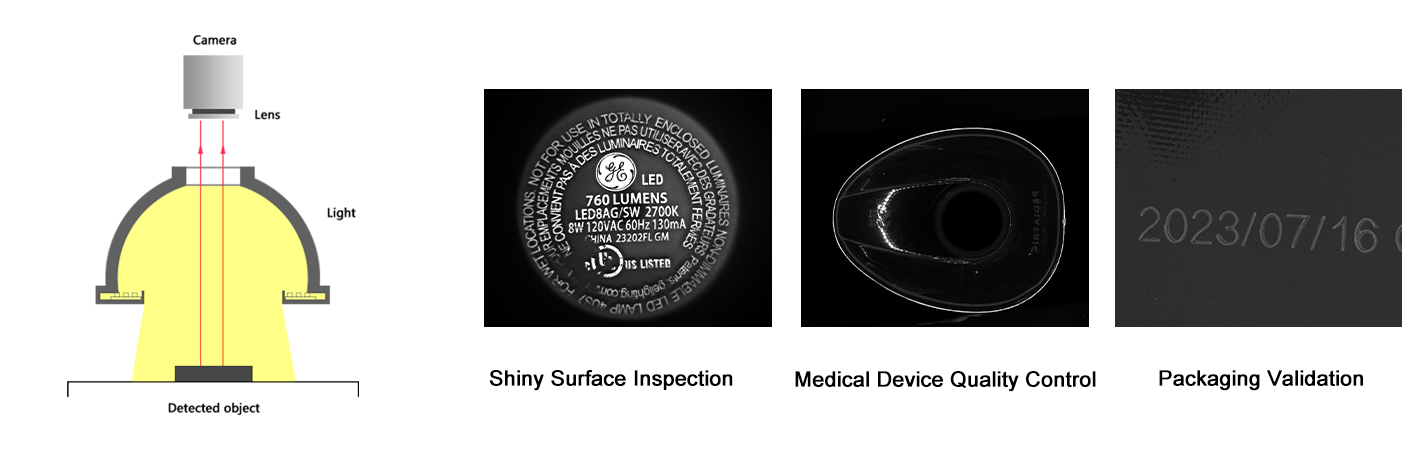

৪. ডোম লাইট: প্রতিফলিত ছবি ছাড়াই চিত্রণ

তারা কিভাবে কাজ করে: ডোম লাইট একটি বক্র ডিফাসার মাধ্যমে আলো সমতুল্যভাবে ছড়িয়ে দেয়, এটি মেঘাচ্ছন্ন আকাশের প্রভাব অনুকরণ করে।

শ্রেষ্ঠ সituationsয়ে:

জ্বলজ্বলে পৃষ্ঠের পরিদর্শন: ধবধবে আলোর ব্যাঙ্কিং ছাড়াই ধাতব ক্যান বা গ্লাসের উপর খোসা পরীক্ষা করা।

চিকিৎসায়িক যন্ত্রপাতি মান নিয়ন্ত্রণ: প্রতিফলিত চিকিৎসায়িক যন্ত্রপাতির অসম্পূর্ণতা পরীক্ষা করা।

প্যাকেজিং ভালিডেশন: আলোক প্রতিফলন ছাড়াই ফয়েল বা ধাতব প্যাকেজিং-এর দোষ পরীক্ষা করা।

এটি কেন কাজ করে: ডাইফিউজ আলো হট স্পট এবং প্রতিফলন বাদ দেয়, যা প্রতিফলিত বা বক্র পৃষ্ঠের জন্য আদর্শ।

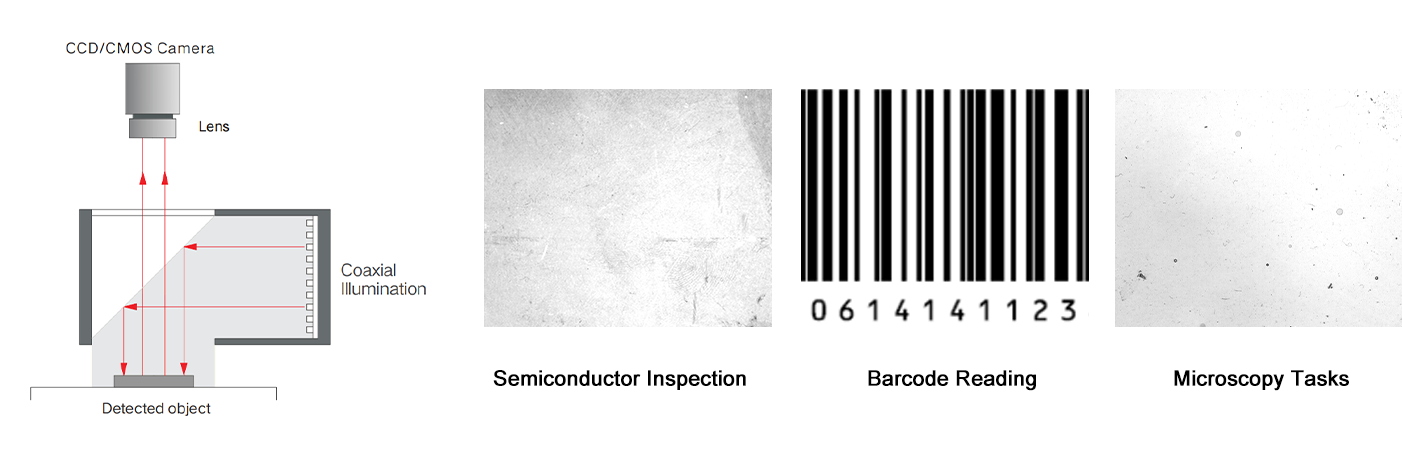

৫. কোঅক্সিয়াল লাইটস: অন-অক্সিস প্রেসিশন

তারা কিভাবে কাজ করে: কোঅক্সিয়াল লাইটস একটি বিম স্প্লিটার মাধ্যমে আলো ঝালায়, আলোকের ক্যামেরার দৃষ্টির সাথে সমান্তরাল হয়।

শ্রেষ্ঠ সituationsয়ে:

সেমিকনডাক্টর পরীক্ষা: সমতল, প্রতিফলিত ওয়াফারের জন্য মাইক্রো-দোষ বিশ্লেষণ।

বারকোড পড়া: চমকতে বা টেক্সচারযুক্ত পৃষ্ঠে পরিষ্কার স্ক্যান নিশ্চিত করুন।

অণুস্কোপ কাজ: ছোট, প্রতিফলিত বস্তুতে মাইক্রো বিস্তারিত ধর্ম ধরুন।

এটি কেন কাজ করে: অক্ষের আলো সমতল, প্রতিফলিত পৃষ্ঠে ছায়া এবং প্রতিফলন কমিয়ে দেয়।

আপনার ঘটনার জন্য আলো মেলানো

আপনি যদি জানতে না পারেন যে কোন আলো আপনার প্রয়োজনের জন্য উপযুক্ত, এখানে একটি দ্রুত গাইড:

সমতল বা প্রতিফলিত পৃষ্ঠ: স্পষ্টতা জন্য রিং লাইট বা কোঅক্সিয়াল লাইট ব্যবহার করুন।

চলমান বা ব্যাপক বস্তু: বার লাইটস লাইন-স্ক্যান ক্যামেরার সাথে জোড়া করা যাওয়ার উপায়।

জ্বলজ্বলে বা বক্র অংশ: ডোম লাইটস গ্লার কমায় যা ছবি তৈরিতে দোষহীন ফলাফল দেয়।

প্রান্ত বা আকৃতি বিশ্লেষণঃ ব্যাকলাইটস আপনার প্রয়োজনীয় কন্ট্রাস্ট প্রদান করে।

আপনার বস্তুর মatrial, আকৃতি এবং গতি বিবেচনা করুন, তারপর ভিন্ন ভিন্ন আলো পরীক্ষা করুন যা সেরা কাজ করে।

বাস্তব জগতের উদাহরণ

খাদ্য প্রসেসিং: একটি বার লাইট এপপেলের একটি ট্রান্সপোর্টারকে আলোকিত করে, যা ক্যামেরাকে মিনিটে ১,০০০ ইউনিট বিচ্ছিন্নতা খুঁজতে দেয়।

ইলেকট্রনিক্স: রিং লাইটস সার্কিট বোর্ড পরীক্ষা করতে সাহায্য করে, একক আলোর অধীনে চুলের মতো ফাটল প্রকাশ করে।

ফার্মাসিউটিক্যালস: ব্যাকলাইটস গোলের বোতলের সঠিক পূরণ স্তর নিশ্চিত করে তাদের বিষয়বস্তুর ছায়া ছবি তৈরি করে।

এই উদাহরণগুলি দেখায় যে সঠিক আলো গুণবত্তা নিয়ন্ত্রণে সমস্ত পার্থক্য করতে পারে।

আলোকিত সেটআপ প্রতিষ্ঠার জন্য টিপস

কোণ সমায়ojন করুন: আলোর অবস্থান পরীক্ষা করুন যাতে কন্ট্রাস্ট বাড়ানো বা গ্লেয়ার কমানো যায়।

ফিল্টার ব্যবহার করুন: পোলারাইজার বা ডিফিউজার দ্বারা কঠিন পৃষ্ঠের জন্য আলো মাঝারি করা যায়।

ওয়েভলেঙ্ক মিলিয়ে নিন: লাল আলো ধাতুর জন্য ভালো হতে পারে, যখন নীল আলো প্লাস্টিকের জন্য উজ্জ্বল করে।

ক্যামেরা সঙ্গতিপূর্ণ করুন: আপনার আলোর তীব্রতা এবং সময় আপনার ক্যামেরার ধারণ হারের সাথে মিলিয়ে নিন।

অবিচ্ছেদ্য আলোকরণের ফলাফল

সঠিক আলোকরণ শুধু ছবির গুণগত মান উন্নয়ন করে না—এটি আপনার সম্পূর্ণ অপারেশনকে উন্নত করে:

কম ভুল: স্পষ্টতর ছবি অর্থ হল আরও সঠিক পরিদর্শন।

তাড়াতাড়ি ফলাফল: অপটিমাইজড আলোক রিস্ক্যানের প্রয়োজনকে কমিয়ে দেয়।

খরচ সাশ্রয়: আগেই খাটি ধরার ফলে ব্যয় এবং পুনর্গঠন কমে।

স্কেলেবিলিটি: সঠিক সেটআপ আপনার উৎপাদন প্রয়োজনের সাথে বৃদ্ধি পায়।

এক কথায়, চালাক আলোক হল ছোট বিনিয়োগ কিন্তু বড় প্রভাব।

আজই আপনার মেশিন ভিশনকে আলো দিয়ে জ্বালুন!

রিং লাইট থেকে ব্যাকলাইট পর্যন্ত, প্রতিটি মেশিন ভিশন আলোক উৎসের একটি অবস্থান আছে যেখানে এটি উজ্জ্বল হয়। আপনার অ্যাপ্লিকেশনের সাথে আলোকের মিল করে আপনি আপনার ভিশন সিস্টেমের সম্পূর্ণ স্বচ্ছতা খুলে দেবেন, যেন প্রতিটি ধাপেই সঠিকতা ও দক্ষতা নিশ্চিত করা যায়।

আপনার লাইনের জন্য পুরনো আলো খুঁজতে প্রস্তুত? আমাদের মেশিন ভিশন আলোক সমাধানের সেট পর্যালোচনা করুন বা আমাদের বিশেষজ্ঞদের সাথে যোগাযোগ করুন জন্য ব্যক্তিগত পরামর্শ। খারাপ আলোক আপনার সফলতাকে অন্ধকার করে না দিন—আজই HIFLY-এর সাথে যোগাযোগ করুন এবং আপনার পথ পুর্ন আলোকিত করুন!