Hochauflösende Objektive für die industrielle Bildverarbeitung: Verbesserung der Bildschärfe in der Präzisionsfertigung

In der Präzisionsfertigung können mikroskopische Defekte oder Messfehler Millionen kosten. Hochauflösende Maschinenvisionslinsen fungieren als entscheidende „Augen“, die eine unübertroffene Bildschärfe liefern und visuelle Daten in handlungsfähige Qualitätskontrolle umwandeln.

Jenseits von Megapixeln: Die optischen Grundlagen der Klarheit

Hochauflösende Linsen gehen über die Pixelanzahl hinaus. Der wahre Wert liegt in fortschrittlicher optischer Ingenieurskunst:

1. Hervorragende MTF-Leistung stellt sicher, dass feine Details scharf bleiben, was für die Erkennung von Haarrissen auf Halbleiterwafern oder Mikrokontaminationen in medizinischen Geräten entscheidend ist.

2. Nahezu keine Verzerrung (<0,1 %) garantiert geometrische Genauigkeit bei der Messung von Mikron-Toleranzen bei Zahnrädern oder Steckverbindungen.

3. Präzise Telezentrikität beseitigt Perspektivenfehler während der robotergestützten Montage von Automobilkomponenten. Ohne diese optischen Grundlagen könnten selbst Kameras mit hoher Megapixelzahl kritische Fehler übersehen.

Lösen der anspruchsvollsten Herausforderungen im Präzisionsfertigungsbereich

Detektion von Defekten im Submikronbereich: Das Unsichtbare sichtbar machen

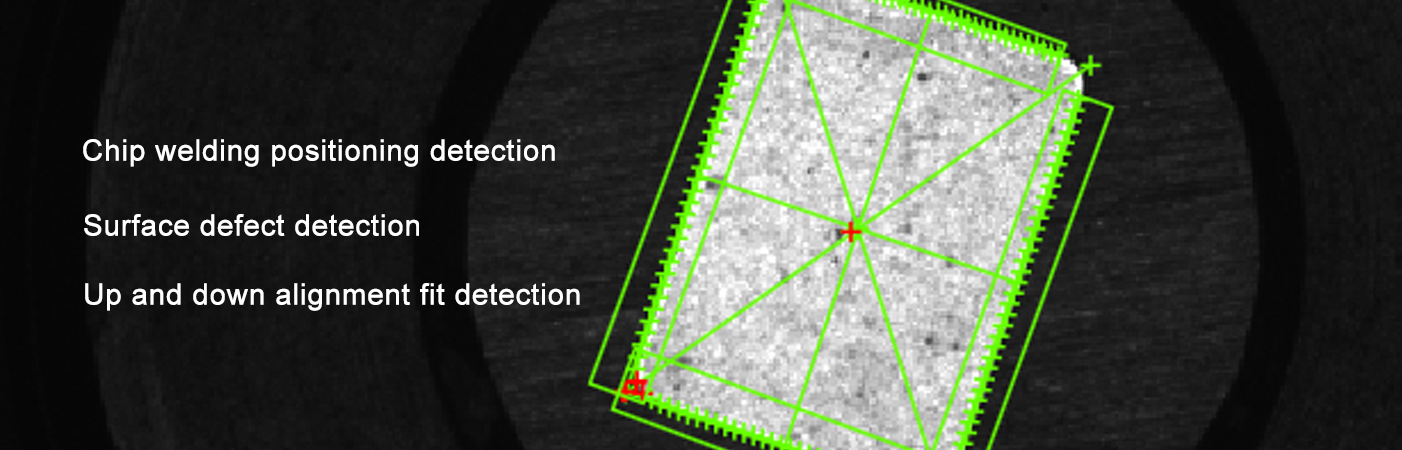

Herkömmliche Linsen könnten Defekte unter 10µm übersehen. Hochauflösende Alternativen erfassen Mikrokratzer auf optischen Linsen oder Lötvolumina in Leiterplattenbaugruppen. Diese Fähigkeit könnte die Ausschleuderquote um über 60 % reduzieren und damit direkt Verschrottungskosten senken.

Dimensionelle Messtechnik im Mikrometerbereich

In der Luftfahrt oder bei der Fertigung von EV-Batterien kann eine Messabweichung von ±5µm zur Ablehnung von Bauteilen führen. Linsen mit geringer Verzerrung in Kombination mit telezentrischer Optik ermöglichen wiederholbare Genauigkeit bei der Prüfung von Turbinenschaufeln oder Elektrodenbeschichtungen in Batterien.

Hochgeschwindigkeitsklarheit ohne Bewegungsunschärfe

Wenn Produktionslinien Geschwindigkeiten von über 200 m/min erreichen, beeinträchtigt Bildunschärfe die Inspektion. Großaperturlinsen (z. B. f/2,4) ermöglichen kürzere Belichtungszeiten und halten Bewegungen z. B. in der Folienproduktion oder bei der Kontrolle von Pharmazeutischen Blisterpackungen klar fest.

Widerstandsfähigkeit gegen extreme Umweltbedingungen

Vibrationen in Automobilwerken oder Staub in Metallverarbeitungsbetrieben beeinträchtigen die Bildqualität. Geschlossene Gehäuse (IP67-zertifiziert) und temperaturstabile Materialien gewährleisten eine zuverlässige Leistung der Objektive von -10 °C bis 55 °C.

Anpassungsfähigkeit: Der Schlüssel zu Ihren individuellen Anforderungen

Fertiglinsen passen selten zu komplexen Anwendungen. Führende Anbieter wie HIFLY begegnen diesem Problem mit maßgeschneiderten Lösungen:

1. Optische Anpassung : Optimierte Beschichtungen für UV-Inspektionen oder Designvarianten mit erweiteter Schärfentiefe für ungleichmäßige Oberflächen.

2. Mechanische Anpassbarkeit : Kompakte Bauformen für Roboterarme oder spezielle Flanschmontagen für Altanlagen.

3. Umweltbeständigkeit : Konforme Beschichtungen für chemische Beständigkeit oder stoßdämpfende Halterungen für vibrationsanfällige Bereiche. Ein Hersteller von Medizingeräten reduzierte Fehlabschaltungen um 45 %, indem er Objektive anpassen ließ, die speziell für die Hinterbeleuchtungsinspektion von Silikondichtungen entwickelt wurden.

Partnerauswahl: Technische Abstimmung vor Datenblättern

Die Auswahl hochauflösender Objektive erfordert mehr als den Vergleich von MTF-Diagrammen:

1. Sensor-Objektiv-Abstimmung : Passen Sie die Pixeldimension an (z. B. benötigen 2,5µm-Sensoren Objektive mit einer Auflösung von 200 lp/mm).

2. Anwendungsvalidierung : Simulieren Sie reale Szenarien – z. B. Blendung durch polierte Metalle oder strukturarme Oberflächen.

3. Lebenszyklusunterstützung : Suchen Sie Partner, die optische Simulationen, Prototyping und Langzeit-Stabilitätstests für Komponenten anbieten. Eine kooperative Herangehensweise stellt sicher, dass Objektive nahtlos in automatisierte Inspektionssysteme oder Messtechnikstationen integriert werden.

Der klare Weg nach vorn

Hochauflösende Objektive für die industrielle Bildverarbeitung sind keine Luxuskomponenten mehr – sie sind strategische Werkzeuge, die die Präzisionsfertigung verändern. Von der Vermeidung von Nanodefects in Halbleitern bis hin zur Roboter-gestützten Mikromontage trägt optische Klarheit direkt zu höheren Ausbeuten, Effizienz und Konformität bei.