How Line Scan Cameras Work in Industrial Applications: Advantages Over Area Scan Cameras Explained

In the fast-paced world of industrial automation, cameras aren’t just tools—they’re the backbone of precision. Enter line scan cameras: the unsung heroes of machine vision that capture images one razor-thin line at a time. But how do they work, and why might they outshine the more familiar area array cameras? Whether you’re inspecting a speeding conveyor belt or ensuring flawless packaging, understanding these technologies can transform your operation.

In this post, we’ll unravel the mechanics of line scan cameras and spotlight their edge over area scan cameras. From high-speed scanning to cost savings, we’ll break it down in plain terms so you can see why this tech matters. Ready to line up the facts? Let’s get started!

What Are Line Scan Cameras?

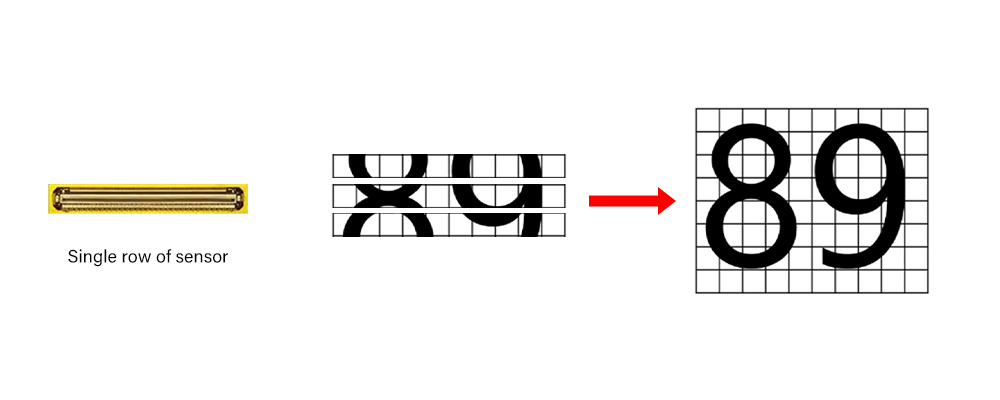

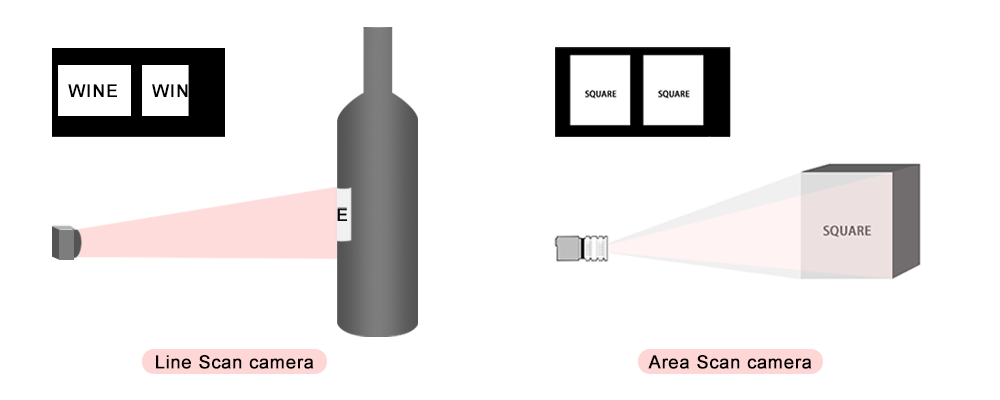

Line scan cameras—often called line array cameras—are specialized industrial tools that capture images one line of pixels at a time, rather than snapping a full frame like a traditional camera. Picture a scanner at your grocery checkout, but turbocharged for industrial use. These cameras use a single row of sensors (a linear array) to build images as objects move past them, stitching each line together into a seamless whole.

How They Work

Step 1: Motion Matters: The object—like a sheet of metal or a roll of fabric—moves across the camera’s field of view, usually on a conveyor.

Step 2: Line-by-Line Capture: The camera’s sensor grabs a thin slice of the scene with each pass, triggered by precise timing or an encoder.

Step 3: Image Assembly: Software combines these lines into a continuous, high-resolution image, ready for analysis.

Think of it like painting a picture with a single brushstroke at a time, but so fast and accurate you’d never know the difference. This method shines in industries where speed and detail are non-negotiable.

Area Scan Cameras: The Familiar Alternative

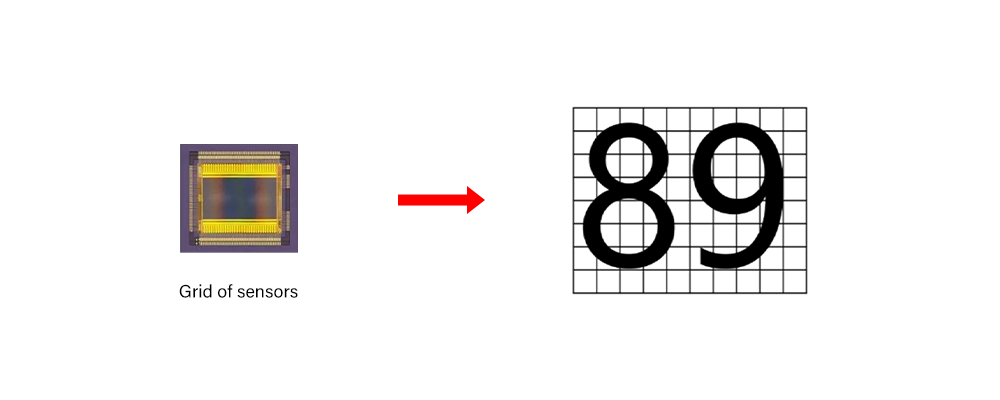

To appreciate line scan cameras, let’s compare them to area scan cameras—the standard you might recognize from your smartphone. These cameras use a grid of sensors (a 2D array) to capture an entire scene in one shot. They’re versatile and intuitive, snapping full frames instantly. But as we’ll see, they don’t always keep pace with line scan tech in industrial settings.

Advantages of Line Scan Cameras Over Area Scan Cameras

So, why choose line scan over area scan? Here’s where they pull ahead:

1. Unmatched Speed for Continuous Motion

Line Scan Win: Designed for objects in constant motion, line scan cameras scan at blazing speeds—think thousands of lines per second. They’re perfect for inspecting endless streams like paper rolls or steel coils.

Area Scan Limit: Area cameras need the object to pause (or use a strobe light) to avoid blur, slowing down high-speed lines.

2. Higher Resolution Without Breaking the Bank

Line Scan Win: A single-line sensor can pack dense pixels (e.g., 8K or more), delivering ultra-sharp images of wide or long objects without needing expensive, massive 2D sensors.

Area Scan Limit: High-resolution area cameras scale up costs fast—a 4K area sensor is pricier and still might not match a line scan’s detail over large surfaces.

3. Seamless Imaging of Large or Cylindrical Objects

Line Scan Win: They excel at”unrolling” curved surfaces—like bottles or pipes—into flat, distortion-free images. No stitching multiple frames together.

Area Scan Limit: Area cameras struggle with wide or round objects, often requiring multiple shots and complex post-processing.

4. Better Light Efficiency

Line Scan Win: Focusing light on a single line means brighter, clearer images, even in tricky lighting. Pair them with a line light source, and you’ve got a powerhouse.

Area Scan Limit: Area cameras spread light across a whole frame, sometimes losing contrast in dim conditions.

5. Compact Data, Big Results

Line Scan Win: By capturing only what’s needed, line scan cameras generate leaner data streams, easing the load on processing systems.

Area Scan Limit: Full-frame images can bog down software with unnecessary pixels, especially in simple inspections.

Where Line Scan Cameras Shine

Printing Industry: Checking ink alignment on high-speed presses.

Textile Manufacturing: Spotting weave flaws in fabric rolls.

Food Processing: Inspecting conveyor belts for defects in packaging or produce.

Area scan cameras still have their place—think static inspections like reading a label or analyzing a stationary part. But for continuous, high-speed, or large-scale tasks, line scan cameras take the lead.

Key Considerations Before Choosing

Motion: Is your target moving? Line scan thrives here; area scan suits still shots.

Field of View: Wide or long objects favor line scan; compact scenes fit area scan.

Budget: Line scan setups might need synchronized lighting or conveyors, but their efficiency can offset costs long-term.

Software: Ensure your vision system supports line scan data processing.

Why It’s Worth the Switch

Line scan cameras aren’t just a niche tool—they’re a game-changer for industries chasing speed and precision. Their ability to handle motion, deliver detail, and streamline workflows gives them a clear edge over area scan cameras in the right scenarios. It’s not about replacing one with the other; it’s about picking the best fit for your line.

Ready to See the Difference?

Curious if line scan cameras could boost your operation?

Don’t guess—get the facts. Explore our range of industrial line scan solutions or reach out to our machine vision experts for a custom demo. From concept to conveyor, we’ll help you find the perfect camera. Contact HIFLY today and start capturing every detail that matters!