Cara Memilih Lensa FA yang Sempurna untuk Visi Mesin: Panduan Komprehensif Pengantar

Dalam dunia visi mesin yang berkembang pesat, memilih lensa FA (Factory Automation) yang tepat sangat penting untuk mencapai ketepatan, kejelasan, dan efisiensi dalam aplikasi pencitraan Anda. Baik Anda sedang memeriksa komponen di jalur produksi maupun mengembangkan robotika mutakhir, pemilihan lensa yang tepat dapat menentukan kinerja sistem Anda. Panduan ini memberikan penjelasan sederhana tentang proses pemilihan lensa FA, serta wawasan praktis agar Anda dapat membuat keputusan yang tepat. Simak terus untuk mempelajari cara mengoptimalkan pengaturan visi mesin Anda dengan lensa yang sempurna!

Mengapa Lensa FA Penting dalam Machine Vision

Lensa FA adalah fondasi dari setiap sistem machine vision, menentukan kualitas gambar, kedalaman bidang, dan akurasi keseluruhan. Lensa khusus ini dirancang untuk memenuhi tuntutan ketat aplikasi industri, memastikan citra berkualitas tinggi dalam kondisi menantang seperti pencahayaan yang bervariasi atau operasi berkecepatan tinggi. Memilih lensa yang salah dapat menyebabkan gambar kabur, pengukuran tidak akurat, atau inefisiensi sistem, yang berdampak pada waktu dan biaya.

Pertimbangan Utama dalam Memilih Lensa FA

Untuk memilih lensa FA yang ideal, fokuslah pada faktor-faktor kritis berikut:

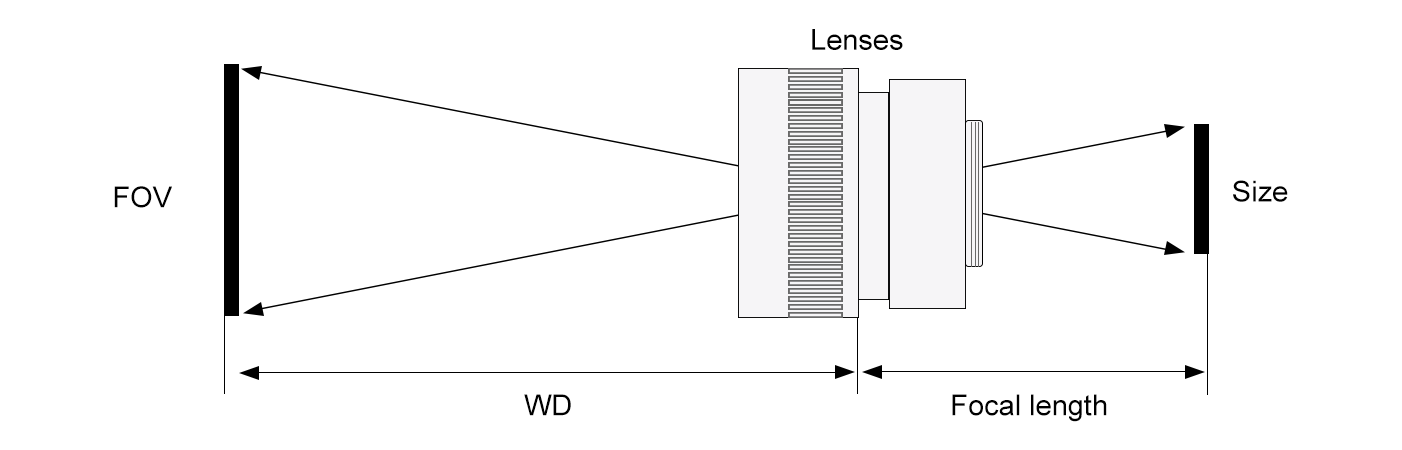

- Jarak Fokus

Panjang fokus menentukan sudut pandang (field of view/FOV) dan pembesaran. Panjang fokus pendek (misalnya, 8mm) memberikan FOV yang lebih luas, ideal untuk menangkap area besar, sedangkan panjang fokus lebih panjang (misalnya, 50mm) menawarkan pembesaran yang lebih tinggi untuk inspeksi detail.

Contoh : Untuk memeriksa komponen elektronik kecil, lensa 25mm atau 35mm mungkin memberikan keseimbangan yang sempurna.

- Kompatibilitas Sensor

Pastikan lensa sesuai dengan ukuran sensor kamera Anda (mis., 1/2", 2/3", atau 1"). Ketidaksesuaian dapat menyebabkan vignetting atau penurunan kualitas gambar. Periksa spesifikasi lingkaran gambar lensa untuk memastikan kompatibilitasnya.

Contoh : Lensa yang dirancang untuk sensor 1" tidak akan berperforma optimal pada kamera sensor 1/3". - Resolusi

Machine vision sering kali membutuhkan lensa berkualitas tinggi untuk menangkap detail halus. Cari lensa yang mendukung resolusi kamera Anda (mis., 2MP, 5MP, atau lebih tinggi). Lensa berlabel megapixel sangat penting untuk kamera modern beresolusi tinggi.

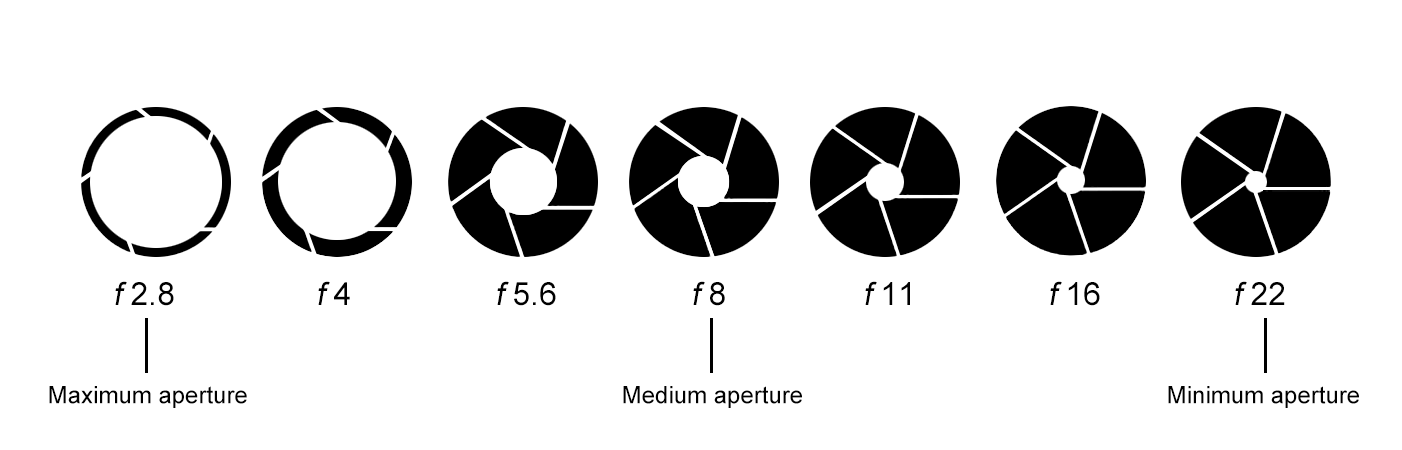

Contoh : Lensa 5MP cocok untuk aplikasi yang memerlukan inspeksi permukaan detail. - Aperture (Nomor-F)

Aperture mengatur jumlah cahaya dan kedalaman bidang. Nilai f-number yang lebih rendah (mis., f/1.4) memungkinkan lebih banyak cahaya masuk, ideal untuk lingkungan minim cahaya, tetapi mungkin mengurangi kedalaman bidang. Nilai f-number yang lebih tinggi (mis., f/8) meningkatkan kedalaman bidang tetapi memerlukan lebih banyak cahaya.

Contoh : Untuk inspeksi conveyor belt kecepatan tinggi, lensa dengan aperture f/2.8 mungkin memberikan keseimbangan antara cahaya dan kejelasan.

- Jarak Kerja

Jarak antara lensa dan objek memengaruhi pemilihan lensa. Lensa panjang fokus tetap dioptimalkan untuk jarak tertentu, sedangkan lensa varifokal menawarkan fleksibilitas untuk jarak yang bervariasi.

Contoh : Untuk jarak kerja 200mm, lensa tetap 16mm mungkin merupakan pilihan terbaik. - Faktor Lingkungan

Pertimbangkan lingkungan operasional—getaran, debu, atau suhu ekstrem dapat memengaruhi kinerja lensa. Pilih lensa dengan konstruksi kokoh, seperti yang memiliki sekrup pengunci atau rumah tahan lama.

Contoh : Dalam pabrik berdebu, pilihlah lensa dengan perlindungan bersertifikasi IP.

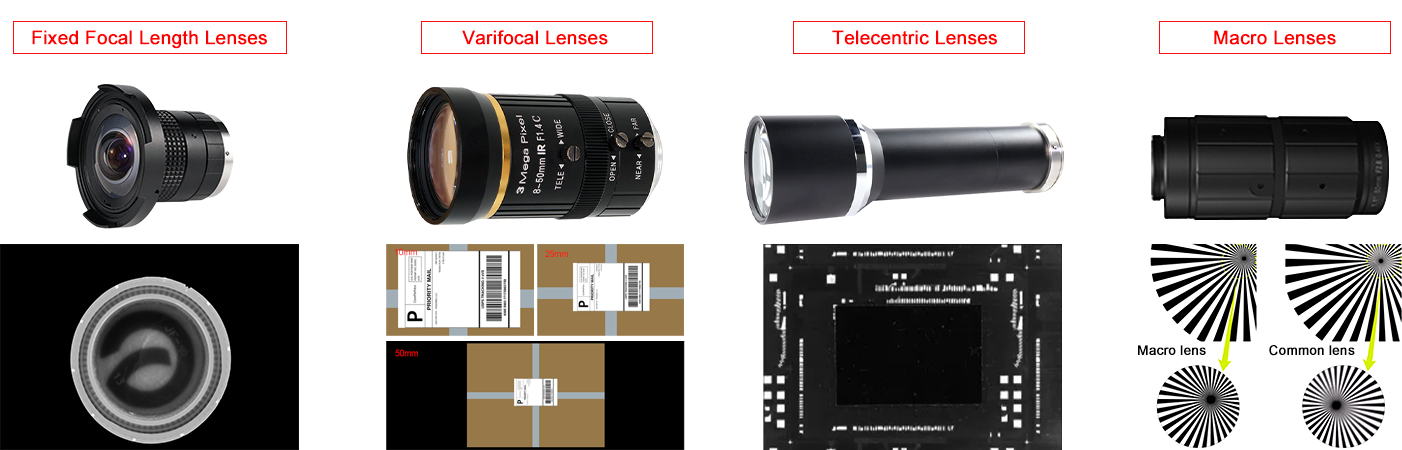

Jenis Lensa FA

- Lensa Focal Length Tetap : Terbaik untuk citra berkualitas tinggi dan konsisten pada jarak tetap. Ideal untuk inspeksi presisi.

- Lensa Varifokal : Panjang fokus yang dapat diatur memberikan fleksibilitas dalam pengaturan dinamis.

- Lensa Telecentric : Menghilangkan distorsi perspektif, sangat cocok untuk aplikasi pengukuran.

- Lensa makro : Dirancang untuk pengambilan gambar close-up, ideal untuk komponen kecil.

Cara Memilih Lensa Sesuai dengan Aplikasi Anda

- Tentukan Aplikasi Anda : Apakah Anda melakukan pemeriksaan, pengukuran, atau identifikasi objek? Setiap tugas memerlukan karakteristik lensa yang spesifik.

- Evaluasi Spesifikasi Kamera : Periksa ukuran sensor, resolusi, dan kecepatan frame untuk mempersempit pilihan lensa.

- Uji dalam Kondisi Nyata : Simulasikan lingkungan kerja Anda untuk memastikan lensa berfungsi dengan baik pada kondisi pencahayaan dan jarak sebenarnya.

- Konsultasikan dengan Ahli : Berkolaborasi dengan pemasok lensa atau konsultan visi mesin untuk memvalidasi pilihan Anda.

Kesalahan Umum yang Harus Dihindari

- Memilih lensa hanya berdasarkan harga, mengabaikan kebutuhan performa.

- Mengabaikan kompatibilitas antara sensor dan lensa, yang menyebabkan kualitas gambar buruk.

- Mengabaikan faktor lingkungan, menyebabkan kegagalan lensa dalam kondisi keras.

- Memilih lensa dengan resolusi yang tidak mencukupi untuk aplikasi berdetail tinggi.

Kesimpulan

Memilih lensa FA yang tepat untuk sistem visi mesin Anda merupakan keseimbangan antara ketepatan teknis dan aplikasi praktis. Dengan memahami panjang fokus, kompatibilitas sensor, resolusi, aperture, dan kebutuhan lingkungan, Anda dapat memastikan sistem Anda memberikan kinerja terbaik. Jangan biarkan lensa yang salah menghambat tujuan otomatisasi Anda—habiskan waktu untuk mengevaluasi opsi Anda secara cermat.

Panggilan untuk Tindakan

Siap meningkatkan sistem visi mesin Anda? Mulailah dengan mengevaluasi kebutuhan spesifik aplikasi Anda dan menjelajahi lensa FA berkualitas tinggi dari pemasok tepercaya. Kunjungi pusat sumber daya kami untuk melihat spesifikasi lensa secara detail atau berkonsultasi dengan ahli visi mesin kami guna menemukan lensa yang sempurna untuk proyek Anda. Optimalkan sistem visi Anda hari ini dan raih presisi yang belum pernah ada sebelumnya!