Industrial Camera "Capture Modes" : Trigger, Synchronization, and Continuous

On industrial automation production lines, you often see machines clicking away as they take pictures—that's industrial cameras at work. Unlike casual smartphone photography, these cameras emphasize timing, rhythm, and even "seamless cooperation."

Today, we explore: How do industrial cameras actually capture images? What are the common acquisition modes? And when should each mode be used?

Ⅰ. How Do Industrial Cameras Capture Images? Four Common Methods

"Taking a picture" for an industrial camera essentially means acquiring an image. This process can operate in several modes:

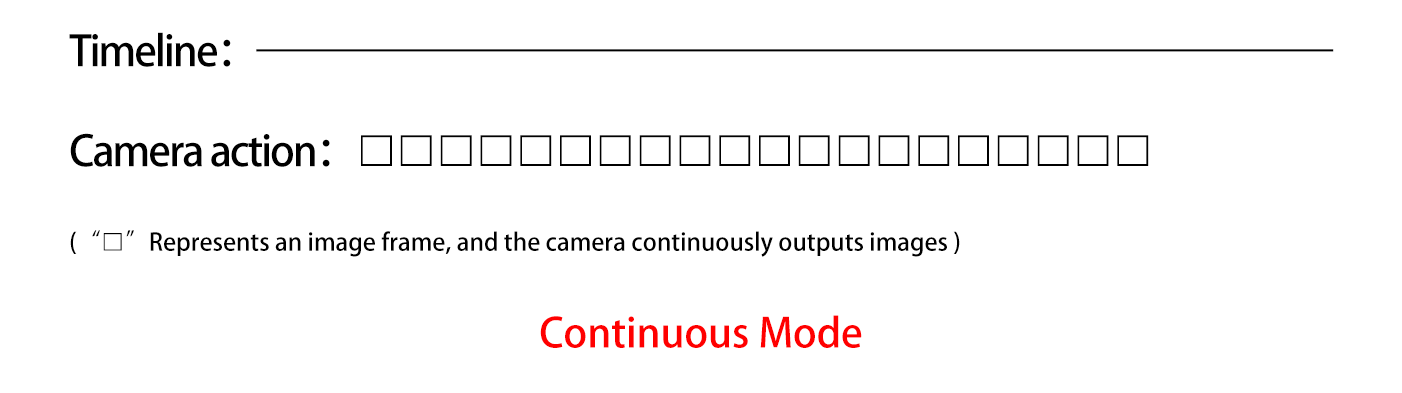

1. Continuous Mode: The camera is always "live streaming"

(1) No trigger conditions are needed; the camera continuously exposes and captures images on its own.

(2) The image stream flows incessantly like a waterfall, suitable for continuous monitoring.

(3) Ideal for: Security surveillance, fixed-pace inspection on conveyor belts, etc.

(4) Pros: Simple and convenient. Cons: Generates many images but lacks precision; cannot control the exact capture moment.

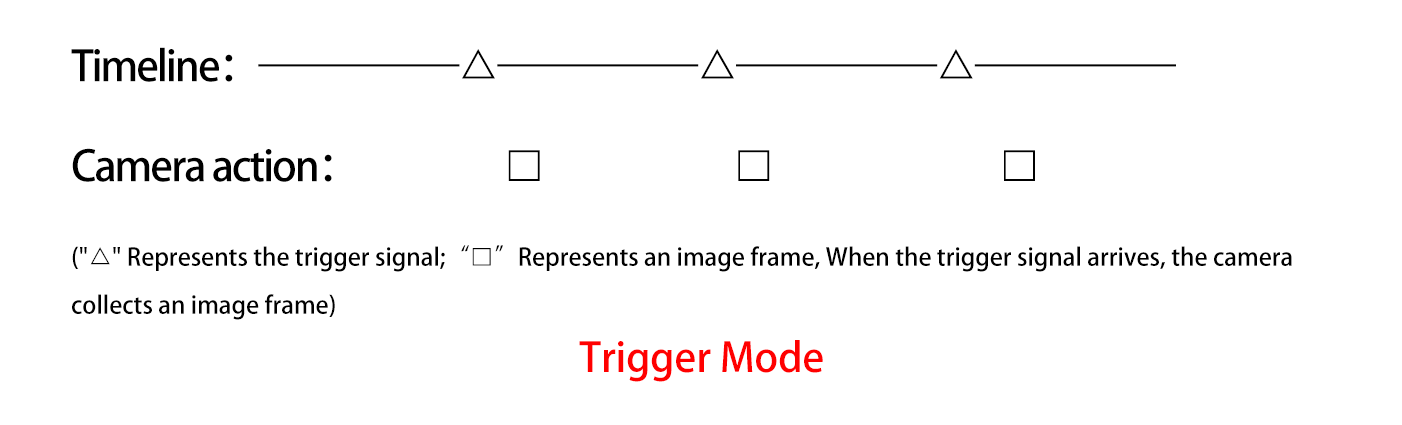

2. Trigger Mode: It only captures when someone says "Capture!"

(1) The camera only captures an image after receiving a "capture command."

(2) This command can come from software (sent by a computer) or hardware (e.g., an electrical signal from a PLC or sensor).

Software Trigger: The host computer controls the camera via code, e.g., calling TriggerSoftware() to capture a single image.

Hardware Trigger: An external device sends an electrical signal (e.g., a rising edge or high level), and the camera responds immediately.

(3)Ideal for: High-speed capture, coordination with robotic arms, image acquisition at precise moments.

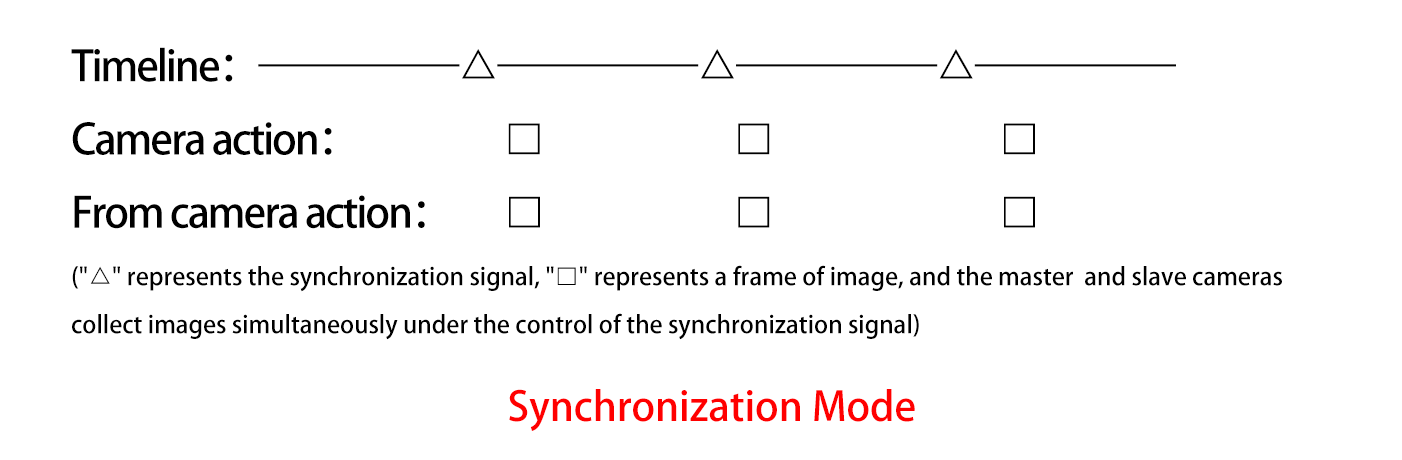

3. Synchronization Mode: Multiple cameras capture together in perfect sync

(1) Like taking a group photo, several cameras receive a unified signal, then expose and capture simultaneously.

(2) Ensures multi-angle images are captured at the exact same time point, without temporal deviation.

(3)Ideal for: Stereo vision, multi-camera machine vision systems, etc.

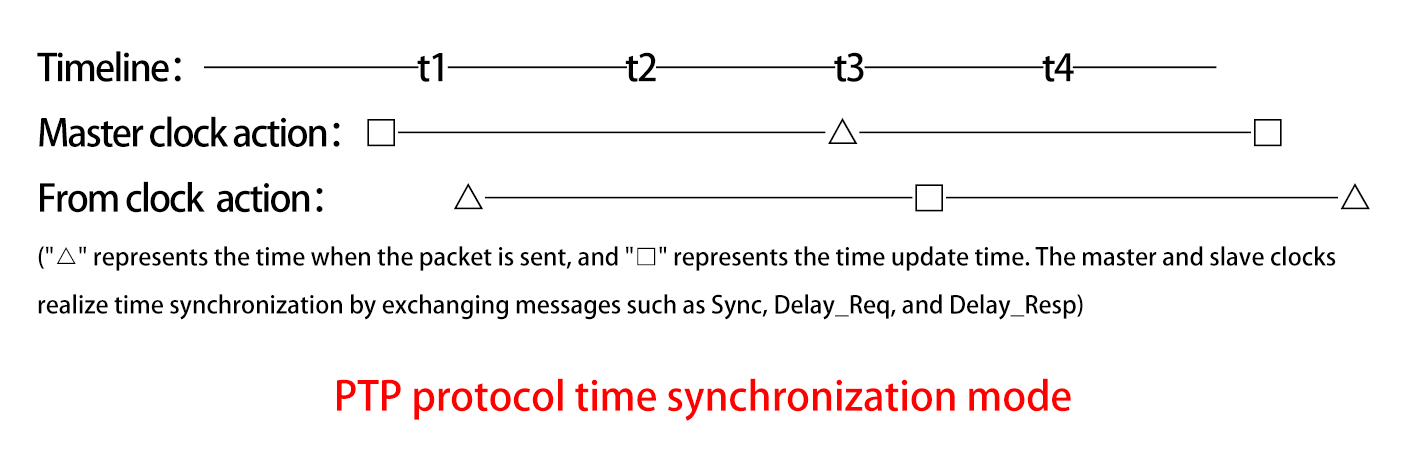

4. Time-Synchronized Mode: Synchronization with a "Clock"

(1) An advanced version of synchronization. Not only do cameras capture simultaneously, but they also record "precise timestamps."

(2) Uses GPS or PTP (Precision Time Protocol) clocks to timestamp every image.

(3) Ideal for: Advanced applications requiring "global time synchronization," such as railway track inspection, long-distance camera systems, etc.

Ⅱ. Where Do Trigger Signals Come From?

Simply put, a trigger signal tells the camera: "Time to take a picture now!"

(1)Software Trigger

• Comes from a command issued by the computer/host.

• Pros: Convenient to use, flexible for debugging.

• Cons: Generally slower response time compared to hardware triggers, with delays around 1–5 ms.

(2)Hardware Trigger

• Comes from external devices like PLCs, sensors, switches, or I/O ports.

• Pros: Fast speed, high stability, delays can be in the microsecond range, suitable for high-speed applications.

• Cons: Requires more wiring and can be more complex to set up.

Ⅲ. What Are the Different Forms of Trigger "Actions"?

The signal isn't just the word "capture"; it comes as a voltage change. Industrial cameras understand the following types:

|

Trigger Mode |

Meaning |

|

Rising Edge |

Voltage jumps from low to high (e.g., from 0V to 24V) |

|

Falling Edge |

Voltage changes from high to low |

|

Either Edge |

Triggered by both rising AND falling edges |

|

High Level |

Voltage remains continuously high |

|

Low Level |

Voltage remains continuously low |

Ⅳ. Two Trigger Modes: Edge vs. Level - What's the Difference?

|

Mode |

How to Understand It |

Suitable Scenarios |

|

Edge Trigger |

The camera captures once when the signal changes (edge). It then ignores the signal state. |

Single frame capture, stable shooting, avoids accidental re-triggers. |

|

Level Trigger |

The camera captures continuously as long as the signal remains active (level). |

Rapid continuous capture, e.g., high-speed production lines. |

Ⅴ. Which Mode is More Suitable for Different Application Scenarios?

|

Scenario |

Recommended Mode |

Reason |

|

Security, General Inspection |

Continuous Mode |

Low effort, real-time viewing |

|

Lab Debugging, Occasional Capture |

Software Trigger |

Simple to control, no wiring needed |

|

High-Speed Production Line Inspection |

Hardware Trigger |

High precision, stable performance |

|

Multi-angle Collaborative Imaging |

Synchronization or Time-Sync |

Simultaneous capture, zero error |

1. Adjacent Color Strategy

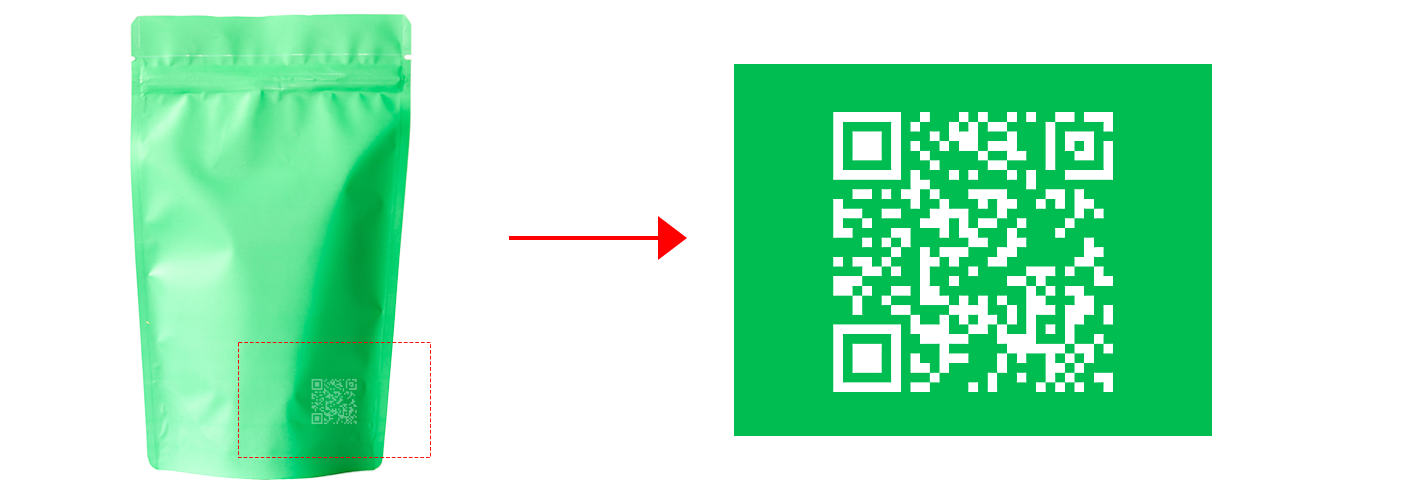

Use a lighting color similar to the target object (e.g., green light for green parts). This brightens the target in the image and "neutralizes" distracting backgrounds—e.g., green patterns on green packaging bags appear faded under green light, avoiding interference with white QR code recognition.

2. Complementary Color Strategy

Use a lighting color opposite to the target object on the color wheel (e.g., red vs. green, blue vs. yellow). This creates strong brightness contrast—e.g., white characters on a green background appear brighter under red light, while the background darkens, significantly improving recognition success rates.

Ⅵ. Summary: The most complex capture mode isn't necessarily the best—the right one is the suitable one!

• Need full coverage, timing isn't critical? Use Continuous Mode.

• Need to control the exact moment, require precise action? Use Trigger Mode.

• Multiple cameras working together? Consider Synchronization or Time-Synchronized modes.

• For experiments or debugging? Software Trigger is often sufficient.

• For high-speed production lines? Hardware Trigger is more reliable.