Machine Vision Color Detection

1. Introduction: Significance and Basic Concept

Machine vision color detection, an integral subset of computer vision technology, leverages image sensors, optical systems, and algorithms to automatically identify, analyze, and quantify color information in objects—replacing subjective human visual judgment with objective, consistent data. Its significance lies in addressing limitations of human perception, such as fatigue-induced errors, inconsistent standards across individuals, and inability to detect subtle color variations (e.g., nanoscale hue shifts), making it indispensable in industries where color accuracy directly impacts product quality, safety, and brand consistency, from consumer electronics to food processing.

2. Core Principles of Color Detection

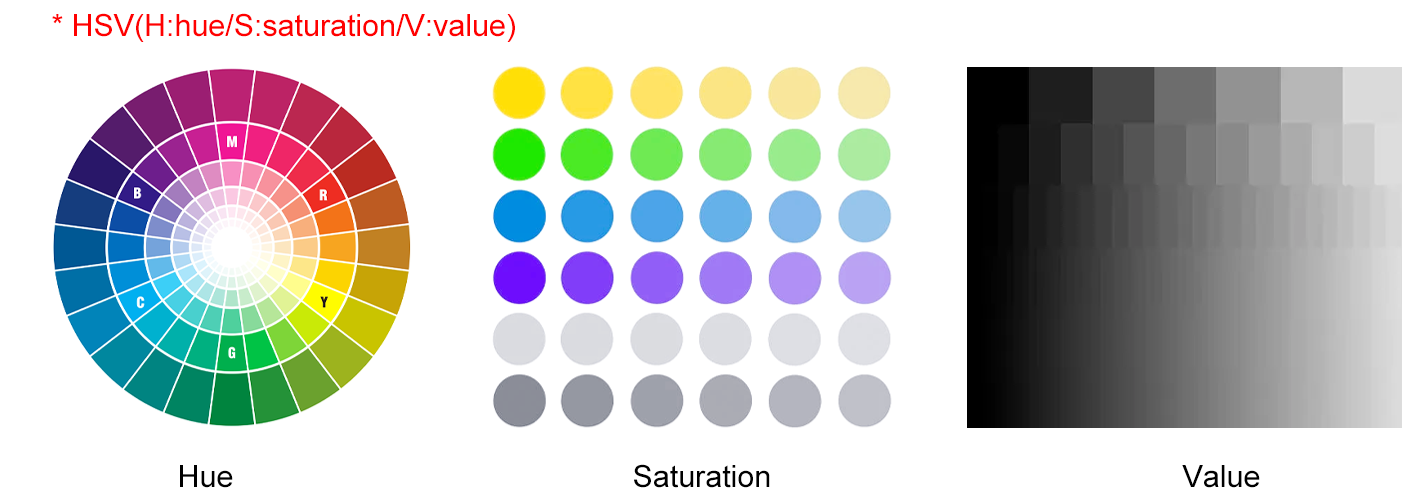

The foundational principle of machine vision color detection revolves around mimicking human color perception but with precise, measurable steps: first, an optical system (including lenses and filters) captures light reflected or transmitted by the target object; second, an image sensor (e.g., CCD or CMOS) converts this light into electrical signals, with each pixel recording intensity values for primary colors (typically red, green, blue, or RGB); third, the system converts raw RGB data into standardized color spaces (such as CIELAB or HSV) to eliminate device-dependent variations, enabling consistent color representation across different cameras or lighting conditions; finally, algorithms compare the processed color data against predefined thresholds or reference samples to determine if the object’s color meets quality requirements.

3. Key Technologies Supporting Color Detection

Several critical technologies underpin effective machine vision color detection: high-resolution image sensors with wide dynamic range ensure accurate capture of color details even in uneven lighting; specialized optical filters (e.g., band-pass filters) reduce ambient light interference and enhance color contrast; color calibration tools (such as color charts and spectrophotometers) maintain consistency by correcting sensor drift or lens distortion; and advanced algorithms, including machine learning models (e.g., convolutional neural networks for complex color classification) and edge detection techniques, enable real-time processing, error reduction, and adaptation to diverse object shapes or surface textures.

4. Practical Applications Across Industries

Machine vision color detection finds widespread use across diverse sectors: in automotive manufacturing, it inspects paint coatings for uniformity and matches interior trim colors to design specifications; in food and beverage production, it sorts fruits by ripeness (e.g., distinguishing red from green apples) and detects color-based defects in products like chocolate or 果汁 (e.g., discoloration from spoilage); in textile and printing industries, it verifies fabric dye consistency and ensures printed materials (e.g., packaging, labels) align with brand color standards; and in electronics manufacturing, it checks LED color accuracy and identifies color-coded components (e.g., resistors) to prevent assembly errors.

5. Current Challenges and Future Trends

Despite its advances, machine vision color detection faces challenges: varying environmental conditions (e.g., changes in ambient light, temperature) can distort color data; highly reflective or transparent surfaces (e.g., glass, metal) complicate accurate color capture; and high-speed production lines demand faster processing without sacrificing precision. Future trends aim to address these issues: integration of hyperspectral imaging (capturing beyond visible light) for more detailed color analysis; adoption of edge computing to enable real-time processing in remote or high-speed settings; development of self-calibrating systems that adapt to environmental changes automatically; and broader use of AI-driven models to handle complex scenarios, such as multi-color object classification or defect detection in irregularly shaped products, further expanding the technology’s versatility and reliability.

6. Conclusion

As industries worldwide continue to prioritize quality control, efficiency, and standardization, machine vision color detection stands out as a transformative technology that bridges the gap between human perception limits and industrial demands. From ensuring the consistency of consumer products to optimizing high-stakes manufacturing processes, its ability to deliver objective, real-time color analysis has already become a cornerstone of modern production. While ongoing challenges like environmental interference and high-speed processing needs persist, the emerging trends of hyperspectral imaging, edge computing, and AI integration promise to unlock even greater potential—making machine vision color detection not just a tool for today, but a driving force for the next era of industrial innovation and quality excellence.