Adakah Frekuensi Gambar Yang Lebih Tinggi Selalunya Lebih Baik untuk Kamera Industri?

Mengapa Kadar Rangka Yang Lebih Tinggi Tidak Sentiasa Lebih Baik untuk Kamera Perindustrian

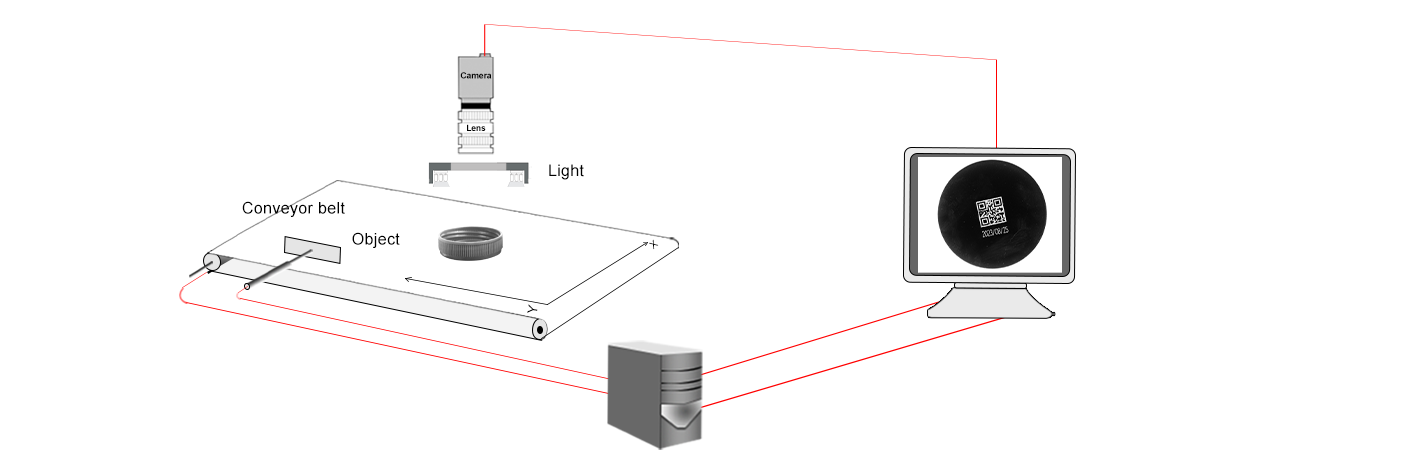

Dalam persekitaran perindustrian, pemilihan sistem kamera yang sesuai adalah kritikal untuk aplikasi seperti pemeriksaan kualiti, panduan robotik, atau pengeluaran kelajuan tinggi. Kadar rangka—berapa banyak imej yang dapat dirakamkan oleh kamera setiap saat—memainkan peranan utama dalam prestasi. Namun, adakah kadar rangka yang lebih tinggi sentiasa merupakan pilihan terbaik? Entri ini meneroka kelebihan dan kompromi berkaitan kadar rangka dalam kamera perindustrian, membantu anda membuat keputusan yang berpandukan keperluan penglihatan mesin anda.

Memahami Kadar Rangka dalam Kamera Perindustrian

Kadar kelajuan bingkai, yang diukur dalam bingkai sesaat (fps), menentukan sekerap mana kamera mengambil imej. Di persekitaran industri, julat kadar bingkai biasanya adalah dari 15 fps untuk pemeriksaan statik sehingga melebihi 100 fps bagi proses kelajuan tinggi seperti talian pengisian botol. Kadar bingkai yang lebih tinggi unggul dalam menangkap objek yang bergerak pantas tanpa kabur pergerakan, memastikan pengesanan kecacatan atau penjejakan yang tepat. Walau bagaimanapun, kadar bingkai hanyalah sebahagian daripada keseluruhan teka-teki—resolusi, saiz sensor, dan kuasa pemprosesan juga mempengaruhi prestasi sistem. Menyeimbangkan faktor-faktor ini adalah kunci untuk mengoptimumkan persetupan anda.

Apabila Kadar Bingkai Yang Lebih Tinggi Bersinar

Kadar bingkai tinggi sangat berharga dalam situasi tertentu. Sebagai contoh, pada garisan pembungkusan yang bergerak pada kelajuan 10 meter sesaat, kamera dengan 60 fps atau lebih tinggi memastikan imej yang jelas bagi setiap produk untuk pemeriksaan kualiti secara masa nyata. Aplikasi seperti pemeriksaan semikonduktor atau pengisihan kelajuan tinggi juga mendapat manfaat, kerana penangkapan bingkai yang pantas mengelakkan kecacatan terlepas pandang. Kamera CMOS 5 MP dengan sensor 1/1.8” pada kadar 60 fps, sebagai contoh, mampu mengendalikan tugas-tugas yang sifatnya pesat sambil mengekalkan keperincian yang mencukupi.

Keburukan Kadar Bingkai Tinggi

Walaupun mempunyai kelebihan, kadar bingkai yang tinggi turut membawa kekurangan. Pertama, ia memerlukan kuasa pemprosesan dan jalur lebar yang tinggi. Kamera yang merakam pada 120 fps pada 5 MP menghasilkan data yang besar, berkemungkinan membebankan sistem anda atau memerlukan peningkatan perkakasan yang mahal. Kedua, kadar bingkai yang lebih tinggi sering kali mengurangkan masa pendedahan, menghasilkan imej yang lebih gelap sekiranya tidak digunakan dengan pencahayaan yang terang, situasi yang meningkatkan kos. Akhirnya, kadar bingkai yang tinggi boleh mengorbankan resolusi, kerana sesetengah kamera memberi keutamaan kepada kelajuan berbanding bilangan piksel, seterusnya mengurangkan kejelasan imej untuk pemeriksaan terperinci.

Cara Memilih Kadar Bingkai Yang Sesuai

Pemilihan kadar bingkai yang optimum bergantung kepada aplikasi anda. Bermula dengan menilai kelajuan objek kerja dan keperluan pemeriksaan. Untuk objek statik atau bergerak perlahan (contohnya, 0.1 m/s), 15-30 fps mungkin mencukupi, dapat mengekalkan resolusi dan meminimumkan kos. Untuk tugas kelajuan tinggi, kirakan kadar fps yang diperlukan menggunakan formula: fps = kelajuan objek (mm/s) / lebar FOV (mm). Untuk FOV 50 mm dan kelajuan objek 200 mm/s, 30 fps adalah mencukupi. Turut pertimbangkan pencahayaan, saiz sensor, dan keupayaan pemprosesan untuk mengelakkan kesempitan. Ujian konfigurasi yang berbeza memastikan keseimbangan terbaik.

Kesimpulan: Buat Pemilihan Kamera Secara Bijak

Kadar kelajuan bingkai yang tinggi bukanlah penyelesaian serba boleh untuk kamera perindustrian. Walaupun ia cemerlang dalam aplikasi kelajuan tinggi, ini boleh meningkatkan kos dan kerumitan tanpa faedah yang setara. Dengan memahami keperluan aplikasi anda—kelajuan, resolusi, dan pemprosesan—anda boleh memilih sistem yang memberikan prestasi optimum. Bersedia untuk memudahkan persediaan penglihatan mesin anda? Terokai panduan pemilihan kamera percintaan kami atau berbincang dengan pakar penglihatan mesin untuk mencari penyelesaian terbaik bagi keperluan perindustrian anda.