Industrial Machine Vision Cameras: Enhancing Precision in Automated Quality Control Systems

Industrial Machine Vision Cameras: Transforming Precision in Automated Quality Control

Modern manufacturing demands flawless precision. As production speeds accelerate and tolerances shrink to micron levels, traditional inspection methods struggle to keep pace. Industrial machine vision cameras have emerged as the backbone of automated quality control, delivering unprecedented accuracy while slashing operational costs. Here’s how these systems redefine precision across industries.

Addressing Critical Quality Control Challenges

Persistent gaps in traditional inspection methods plague high-stakes sectors. In automotive manufacturing, 2D vision systems might miss subtle weld defects or curved-surface scratches, leading to costly recalls. Electronics assembly lines face micro-scale defects in components like Micro LED displays, where human inspectors cannot maintain consistency at high throughput. The pharmaceutical industry grapples with GMP compliance, requiring 100% capsule inspection at speeds exceeding 800 units/minute—far beyond manual capabilities. These scenarios highlight a universal truth: precision gaps directly impact brand reputation and profitability.

Technological Leaps in Vision Camera Capabilities

Industrial machine vision cameras resolve these challenges through hardware and software innovations. Ultra-high-speed sensors capture details at 3,000fps, freezing motion to analyze PCB solder joints or FPC flexing in real-time. Advanced CMOS technology enables reliable defect detection in near-darkness (below 0.001 lux), critical for inspecting sterile pharmaceutical vials.

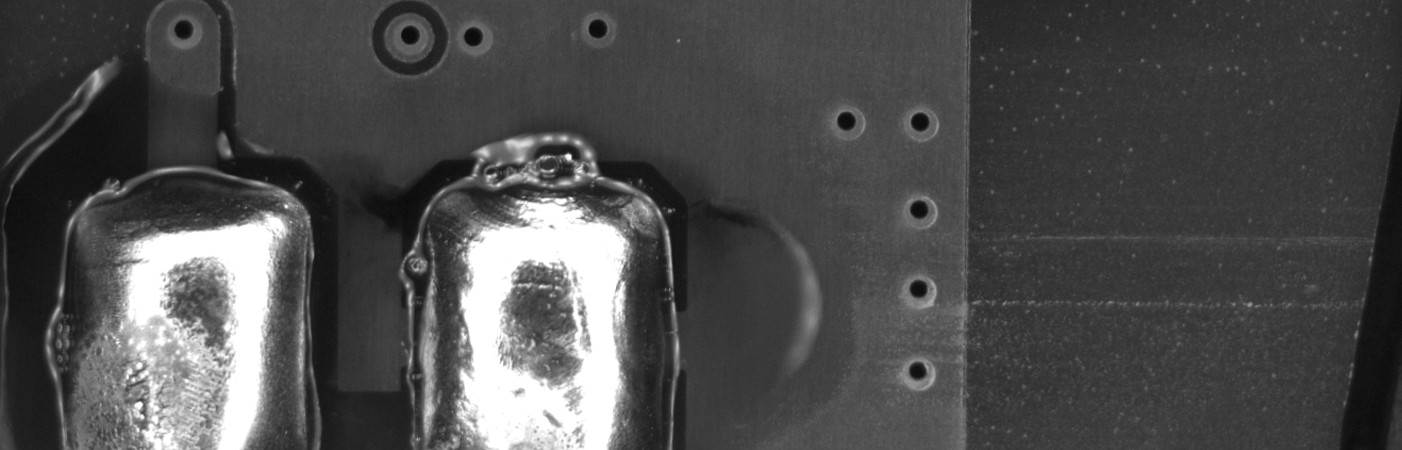

AI integration further elevates precision. Deep learning algorithms trained on minimal defect samples can identify microscopic anomalies—such as battery electrode burrs or semiconductor wafer cracks—with over 99.7% accuracy. This reduces false positives by more than 80% compared to rule-based systems. Adaptive HDR imaging dynamically balances light exposure, eliminating glare on reflective surfaces like metal packaging or automotive chrome parts.

Industry-Tailored Vision Solutions

Custom configurations ensure seamless integration into diverse production environments:

Automotive Manufacturing: 3D laser profiling cameras scan welded seams at micron-level resolution, detecting hairline fractures invisible to 2D systems. One integration reduced rework costs by 45% at a major assembly plant.

Electronics Production: Global shutter cameras with 10μm resolution spot minute defects in chip capacitors during high-speed mounting, cutting customer complaints by 67%.

Pharmaceutical Packaging: Polarization-filter cameras neutralize reflections from blister packs, ensuring 100% pill integrity verification under FDA 21 CFR Part 11 compliance.

Food & Beverage Processing: Multi-spectral imaging identifies contaminants in transparent liquids, decreasing production halts by 32%.

Optimizing System Integration for Real-World Demands

Deploying industrial machine vision cameras requires addressing environmental and scalability factors:

- Extreme Condition Resilience: Ruggedized housings maintain accuracy in temperatures from -30°C to 85°C, ideal for foundries or frozen food facilities. ATEX-certified models operate safely in explosive atmospheres like chemical plants.

- Multi-Camera Synchronization: Precision timing protocols (PTPv2) synchronize camera networks across large-scale inspections. One automotive line uses 16 synchronized units to measure entire vehicle body panels within ±50μm tolerance.

Next-Gen Vision: Intelligence at the Edge

Future-proof systems leverage embedded processing. Industrial machine vision cameras with integrated AI chips analyze defects directly on-device, slashing latency to under 8ms for real-time robotics guidance. Hyperspectral sensors are expanding into food grading, measuring sugar content or bruising without contact.

Why Precision Demands Specialized Vision Partners

Selecting cameras isn’t about specs alone. It requires:

- Domain-Specific Calibration: Optics and lighting tuned for unique surfaces (e.g., curved glass vs. textured metals)

- Scalable Architecture: Seamless integration with controllers and MES software

- Lifecycle Support: Firmware updates and compatibility with evolving AI models

HIFLY’s modular ecosystem—from high-speed cameras to programmable controllers—ensures adaptable solutions. Our engineers collaborate directly to tackle challenges like high-moisture factory environments or ultra-fine component inspections.