The Role of Adaptive Lighting in Machine Vision Systems

Understanding Adaptive Lighting in Machine Vision

What Makes Lighting 'Adaptive' in Industrial Applications

Adaptive lighting in machine vision is a cutting-edge approach that dynamically adjusts lighting conditions in response to real-time changes within industrial settings. This flexibility enables the system to modify intensity, direction, and color temperature based on immediate environmental demands, enhancing inspection processes' efficiency and accuracy. For instance, a ring light might shift its brightness or distribution pattern to highlight specific features of an object being inspected. Key industries, such as automotive and electronics manufacturing, utilize adaptive lighting to improve defect identification and increase throughput. The scientific principles underpinning adaptive lighting involve the interplay between light conditions and object characteristics, allowing for precise control over light delivery. Moreover, adaptive lighting boasts significant benefits, including increased energy efficiency and reduced heat output. These advantages make it a more sustainable choice compared to traditional static lighting systems.

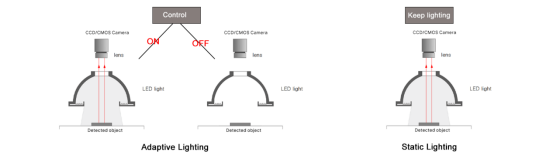

Adaptive vs. Static Lighting: Core Differences

The primary distinction between adaptive and static lighting lies in their operational methodologies. Adaptive lighting systems adjust dynamically based on real-time feedback, while static lighting maintains constant settings. This results in adaptive lighting being more suitable for variable environments, enhancing visual quality and defect detection rates. However, this flexibility comes at a cost; adaptive systems often require higher initial setup investments than static counterparts. Over the long term, though, the enhanced efficiency can result in lower operational costs for adaptive lighting. Research indicates that adaptive systems not only reduce energy consumption but also significantly improve detection accuracy in complex inspection scenarios. For instance, studies show that adaptive lighting can increase defect detection rates by up to 30% compared to static solutions, underscoring its effectiveness in real-world applications.

How Adaptive Lighting Enhances Defect Detection

Adaptive lighting significantly boosts defect detection by adjusting to enhance visibility and optimize inspection conditions. These systems employ adaptive algorithms to modify lighting characteristics within milliseconds, ensuring optimal lighting conditions tailored to each inspection situation. Data from various case studies highlight substantial improvements in defect identification rates due to this precise adaptability. For instance, adaptive systems have been reported to improve detection accuracy by as much as 20%, particularly in industries demanding high precision such as semiconductor manufacturing. The technological prowess of adaptive lighting lies in its ability to instantly switch lighting patterns, magnifying even the tiniest defects that static systems might miss. Metrics such as detection rates and false-positive instances serve as crucial indicators of a lighting system's effectiveness in defect detection, with adaptive lighting consistently outperforming static solutions in these areas.

Key Lighting Configurations for Machine Vision

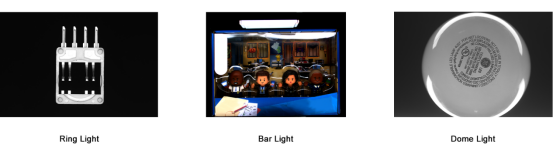

Ring Light Applications in Precision Inspection

Ring lights are pivotal in providing uniform illumination, crucial for inspecting small and intricate components. These lights are strategically placed around lenses to ensure even distribution of light, minimizing shadows that might obscure defects. They are especially effective in quality control processes within industries like electronics manufacturing, where precision is paramount. The technical advantage of ring lights lies in their ability to create high contrast, allowing for the accurate detection of tiny defects. In practice, ring lights have shown to improve inspection outcomes significantly, as evidenced by case studies across various industries where meticulous component analysis is required.

Bar Light Solutions for Conveyor Systems

Bar lighting technology plays an essential role in conveyor systems, enabling efficient and thorough inspections as items move through production lines. By strategically aligning the width, length, and placement of bar lights, coverage on moving objects is maximized, minimizing the likelihood of defect escape. For instance, in food processing and packaging, bar lights are deployed to ensure consistent illumination across conveyors, aiding in the rapid identification of defects. One of the main advantages of using bar lights is their ability to target specific areas without creating shadows, which ensures comprehensive inspections and reduces the risk of missed defects.

Dome Lighting for Surface Reflection Control

Dome lighting is vital for controlling reflections and shadows, especially when inspecting surfaces with challenging contours or high gloss finishes. Its ability to evenly distribute light ensures diffuse reflections, effectively reducing glare and highlighting inconsistencies on the surface. Dome lighting is particularly beneficial in environments like automotive and metalwork industries, where shiny and irregular surfaces are prevalent. Evidence has shown that dome lights outperform traditional lighting methods in such applications, proving crucial for accurate surface inspections and analysis.

Optimizing High-Speed Camera Performance

1000 fps Imaging Challenges in Dynamic Environments

Working with high-speed cameras, especially at 1000 fps, presents distinct challenges. Maintaining image clarity and detail is crucial in such dynamic environments, where motion capture is essential for detailed analysis. One major hurdle is ensuring synchronization between the camera and lighting systems to prevent motion blur and mitigate the effects of ambient light, which can significantly degrade image quality. Industry experts suggest that optimizing high-speed camera performance involves careful calibration and synchronization, as well as selecting the appropriate lighting setup to suit the specific conditions.

Synchronizing Adaptive Lighting With Camera Shutters

Synchronizing camera shutters with adaptive lighting systems is crucial for optimal image capture during high-speed recordings. Proper synchronization ensures that the light intensity and exposure align precisely with the shutter actuation, crucial for achieving clear and high-quality images. Techniques for synchronization include using both hardware solutions, like trigger signals, and software solutions that harmonize the timing of lighting and camera capture effectively. Successful real-world applications have demonstrated that well-synchronized setups can enhance image quality significantly, especially in fast-paced industrial environments.

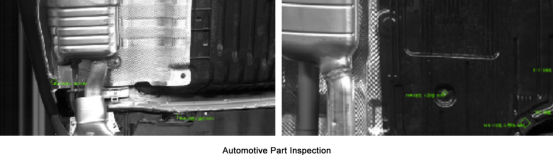

Case Study: Automotive Part Inspection at 1200fps

In a recent case study, high-speed cameras operating at 1200 fps were employed in automotive part inspections, showcasing the critical role of adaptive lighting setups. These setups were tailored to provide consistent lighting conditions, dramatically enhancing inspection precision and defect detection rates. The vehicle parts inspection demonstrated significant operational efficiency improvements, with adaptive lighting systems enabling clear visibility of intricate details. The insights gained from this case study have the potential to influence industry practices, highlighting the efficacy of high-speed imaging coupled with advanced lighting systems for nuanced inspections.

Implementation Strategies for Vision Systems

Balancing Intensity and Frequency in Lighting Control

Achieving the ideal balance between intensity and frequency in lighting is crucial for optimizing machine vision outcomes. The relationship between light intensity and frequency directly affects image capture quality; too much intensity can result in glare, while insufficient frequency could lead to issues like motion blur. Practical strategies for calibrating lighting conditions involve using dimmable LEDs and selecting appropriate lenses that cater to specific applications, ensuring the vision system performs optimally. Expert recommendations often emphasize regular calibration and real-time adjustments to maintain optimal balance, thus enhancing operational efficiency and reducing errors in machine vision tasks.

Integration With Machine Learning Algorithms

Integrating adaptive lighting with machine learning significantly enhances vision systems by enabling them to respond intelligently to changing environmental conditions. Machine learning algorithms can assess lighting conditions and dynamically adapt them for optimum image capture, vastly improving the vision system's accuracy and efficiency. For instance, adaptive lighting systems that use algorithms to adjust brightness and contrast are becoming integral to industries like manufacturing, where precision is paramount. However, merging these technologies presents challenges, such as ensuring compatibility with existing systems and managing the complexity of algorithm training to accurately understand and predict environmental changes.

Future Trends: Self-Adjusting Lighting Ecosystems

The emergence of self-adjusting lighting ecosystems represents an exciting future trend in adaptive lighting technology. Advanced algorithms may lead to fully automated lighting systems that adapt seamlessly to their environments, enhancing machine vision applications across industries. Such ecosystems promise significant advancements in manufacturing and healthcare, where precise lighting conditions can impact performance and outcomes. Experts believe these developments are feasible within the next decade, provided ongoing advancements in algorithmic capabilities and sensor technologies continue. This self-regulatory approach to lighting control holds potential for substantial improvements in operational efficiency and adaptability in dynamic settings.