Mükemmel Yerleştirme, Maksimum Performans: Makine Görüşü ile Röle Isıtıcısının Hizalamasının Sağlanması

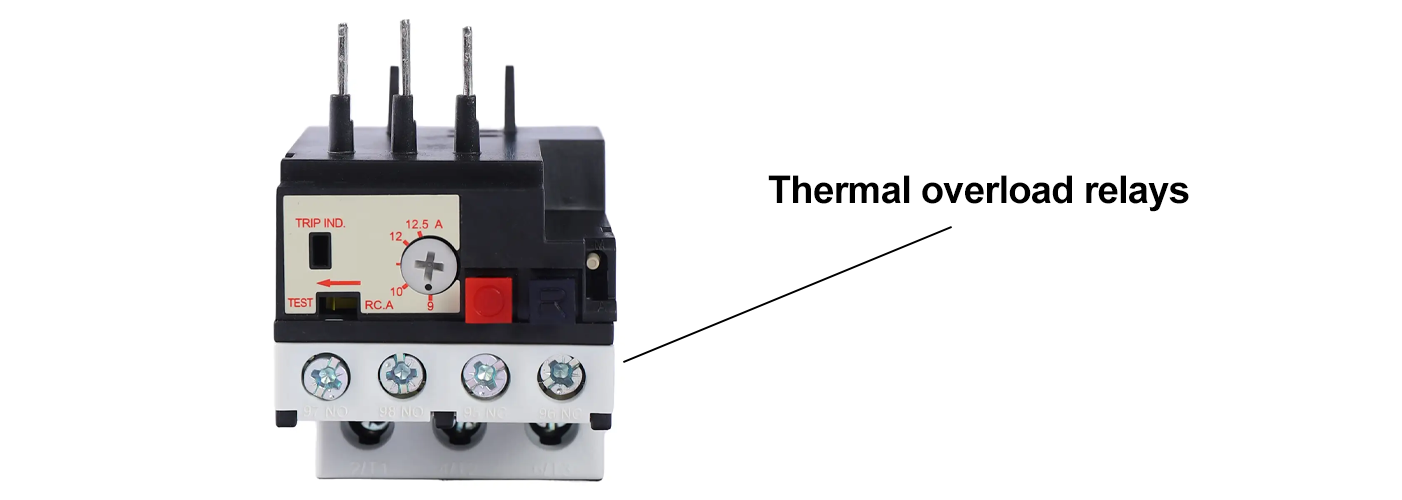

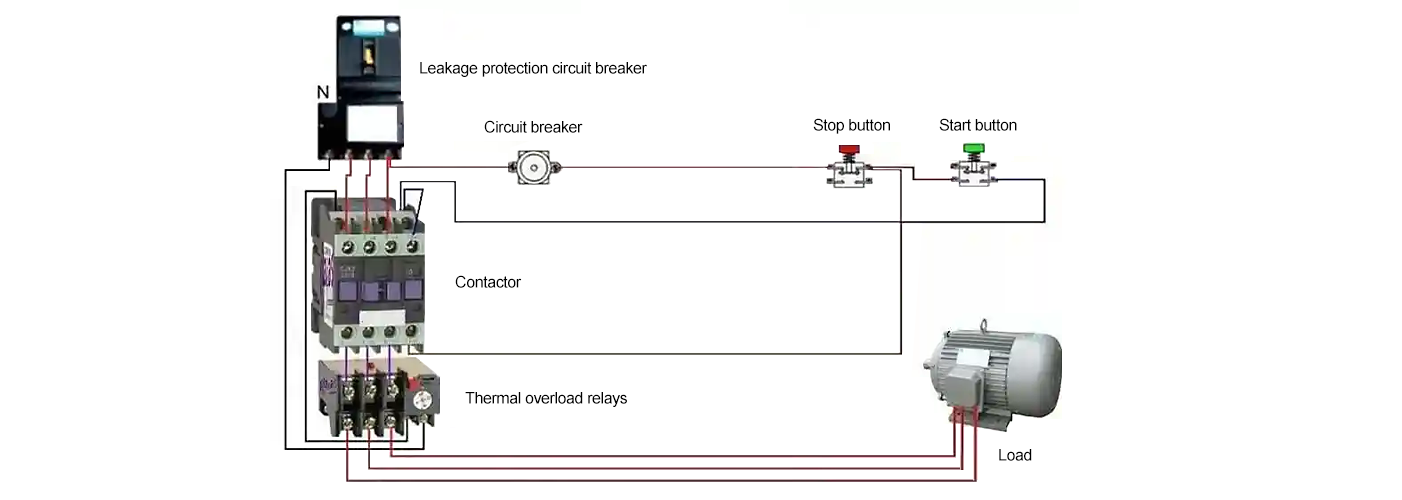

Elektrikli bileşenler dünyasında, bir milimetrenin onda biri dahi güvenilir bir ürün ile felaket arası fark yaratabilir. Bu durum özellikle termal aşırı yük röleleri , motorları ve ekipmanları zararlı akım artışlarından koruyan hayati cihazlar, için geçerlidir. Bu rölelerin temel bileşeni ısıtıcı eleman —ve bunun hassas hizalanması kesinlikle zorunludur.

Bu kritik hizalamanın manuel muayenesi yavaştır, tutarsızdır ve yüksek üretim hızlarında neredeyse imkânsızdır. Bu yüzden üreticiler makine Görseli bu güçlü teknoloji, ısıtıcı elemanın her seferinde mükemmel konumda olmasının sağlanmasını sağlar ve böylece rölenin doğruluğunu, güvenilirliğini ve en önemlisi güvenlik işlevini garanti altına alır.

1. Hassasiyet Zorunluluğu: Neden Hizalama Önemlidir

Röle ısıtıcı elemanın görevi üzerinden geçen akımla orantılı ısı üretmektir. Bu ısı daha sonra aşırı yük gibi tehlikeli bir durum meydana geldiğinde röleyi devreyi kesmek üzere harekete geçiren bimetalik şerit veya diğer termal mekanizmayı tetikler.

Doğruluk: Isıtıcı eleman ile tetikleme mekanizması arasındaki fiziksel boşluk ve paralellik, rölenin açma eğrisini doğrudan etkiler. Yanlış hizalama, rölenin erken açılmasına (istenmeyen duruşlar) veya çok daha kötüsü, geç açılmasına (motor hasarı) neden olabilir.

Tutarlılık: Her röle aynı şekilde performans göstermelidir. Milyonlarca birim boyunca bu eşit performansı garanti edebilmek için yalnızca otomatik ve hassas muayene yapılmalıdır.

Güvenlik: UL, CSA ve diğer güvenlik sertifikaları son derece doğru ve güvenilir koruma cihazları gerektirir. Kusursuz hizalama, bu katı düzenleyici standartlara uymak için temel bir gerekliliktir.

2. Bir İncelemenin Anatomisi: Makine Görüşü Isıtıcıyı Nasıl Hizalar

Makine görüş sistemleri röle montaj sürecine tartışmasız düzeyde titizlik getirir. İşte teknolojinin ısıtıcıyı mükemmel şekilde hizalamasının yolu:

Yüksek Hızlı Görüntüleme: Bir endüstriyel kamera röle montaj alanının net, yüksek büyütme oranlı bir görüntüsünü yakalar. Bu genellikle özel bir telemerkezli lens perspektif hatası olmayan ve bileşenin yükseklik değişikliğine bakılmaksızın doğru ölçüm sağlayabilen görüntü sağlayan

Özel Aydınlatma: Maksimum kontrast elde etmek anahtardır. Arka Aydınlatma ya da yüksek oranda yayılmış kubbe aydınlatması ısıtıcı elemanın siluetini oluşturmak ve arka yapıya karşı kenarlarının keskin ve net bir şekilde ölçülmesini sağlamak amacıyla sıklıkla kullanılır.

Güçlü Yazılım ve Algoritmalar: Sistemin merkezinde, gelişmiş geometrik desen eşleştirme ve kenar algılama aletleri.

(1). Pozisyon Doğrulama: Yazılım, ısıtıcı elemanın anahtar özelliklerinin $(X, Y)$ koordinatlarını hassas bir şekilde ölçer.

(2). Aralık Ölçümü: Isıtıcı eleman ile bitişik bileşen (örneğin, termal açma mekanizması) arasındaki mesafeyi hesaplar ve önceden belirlenmiş dar tolerans aralığı içinde olup olmadığını doğrular.

(3). Oryantasyon Kontrolü: Dönel hataları kontrol eder ve ısıtıcının gerekli pozisyona tamamen paralel olduğundan emin olur.

(4). Geçer/Geçmez Kararı: Sistem, ölçümleri onaylama/reddetme kriterleriyle milisaniyeler içinde karşılaştırır. Hemen üretim hattına bir "REDDEDİLDİ" sinyali gönderilir ve genellikle bir sonraki montaj adımından önce arızalı röleyi reddetmek için bir mekanizma devreye girer.

3. İş Gerekçesi: Güvenilirlik, Üretim Kapasitesi ve ROI

Röle ısıtıcı hizalaması için makine görüşü uygulamak yalnızca teknik mükemmellikten ibaret değildir; net getirisi olan akıllı bir iş kararıdır.

|

Fayda |

Tanım |

|

Kalite garantisi |

İnsan kaynaklı öznellik ve hataları ortadan kaldırarak doğru hizalamanın belgelendirilmiş kanıtıyla %100 denetimi sağlar. |

|

Artan Üretim Kapasitesi |

Yüksek hızlı otomatik montaj hatlarıyla uyum içinde kalınarak milisaniyeler içinde denetim gerçekleştirilir ve üretim darboğazları azaltılır. |

|

Garanti Taleplerinde Azalma |

Hizalama ile ilgili arızaların önüne geçerek sistem, maliyetli saha dönüşlerinin riskini büyük ölçüde düşürür ve marka itibarını korur. |

|

Düzenlemelere uygunluk |

Güvenlik sertifikasyon kurumlarının gerekli kıldığı katı kalite belgelendirme gereksinimlerini karşılayan kapsamlı, izlenebilir veri kayıtları sunar. |

|

Veriye Dayalı İyileştirme |

Toplanan veriler, montaj ekipmanındaki trendleri ve sapmaları ortaya koyar ve bakım ekibinin kritik hatalar meydana gelmeden önce müdahale etmesini sağlar tahmin edici bakım kritik hatalar meydana gelmeden önce. |

4. Devrenizi Güvence Altına Alın. İtibarınızı Güvence Altına Alın.

Termal aşırı yük röleleri gibi güvenliğe kritik öneme sahip cihazlarda ödün vermek mümkün değildir. Müşterileriniz ve değerli makineleri, bileşenlerinizin zorlu koşullar altında kusursuz çalışmasına güvenir. Röle ısıtıcılarının mükemmel hizalanmasını sağlamak için makine görüşü, gerçekten ölçeklenebilir ve güvenilir olan tek çözümdür.

Güvenlik cihazınızın bütünlüğünü şansa bırakmayın. Bugün bizimle iletişime geçin ve özel bir makine görüşü çözümünün kalite kontrolünüzü nasıl otomatikleştirebileceğini ve rölelerinizin gerektirdiği hassasiyeti nasıl sağlayabileceğini öğrenin.