What Are the Differences Between Industrial Cameras and Ordinary Cameras?

Do you know the difference between industrial cameras and ordinary cameras? Do you know which camera is more suitable for your needs? In modern automated production and machine vision systems, industrial cameras play an indispensable role as the "eyes" of industrial equipment. Their technical specifications and performance far exceed those of ordinary consumer-grade cameras, particularly in high-speed imaging, stability, and data transmission. Below is a detailed comparison of the differences between industrial cameras and consumer cameras.

1. High-Speed Imaging Capabilities

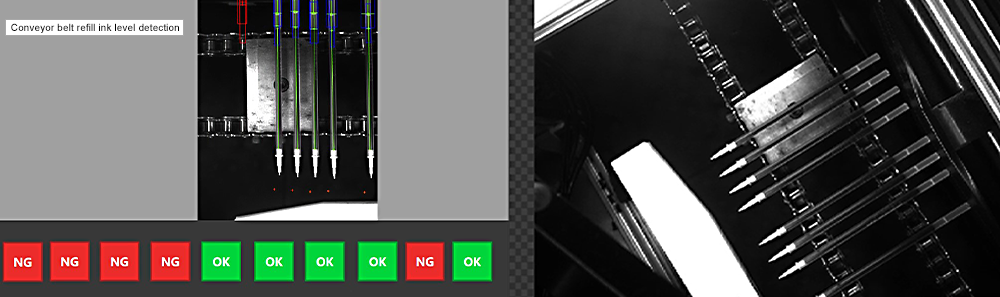

Ultra-high-speed applications on industrial assembly lines are very common, usually requiring cameras with short shutter speeds, fast imaging, and high frame rates. Industrial cameras are designed to meet the demands of ultra-fast applications, such as high-speed assembly lines or rapid motion analysis. They feature ultra-short exposure times, rapid imaging, and high frame rates, often capturing hundreds of images per second. For instance, when inspecting fast-moving objects like rotating machinery parts or conveyor belt components, industrial cameras ensure clear imaging and data accuracy without motion blur. In contrast, consumer cameras, optimized for everyday photography, lack the hardware and software optimizations required for such high-speed scenarios, resulting in blurred images or delayed capture.

2. Stability and Durability

Many industrial scenes require long-term uninterrupted work to ensure product quality inspection, so the stability of the camera is crucial in visual inspection. Industrial cameras are not only stable and can work for a long time, but can also be used in harsh environments. Conversely, consumer cameras are prone to overheating, shorter battery life, and operational failures under prolonged or strenuous use, making them unsuitable for industrial applications.

3. Data Transmission Efficiency

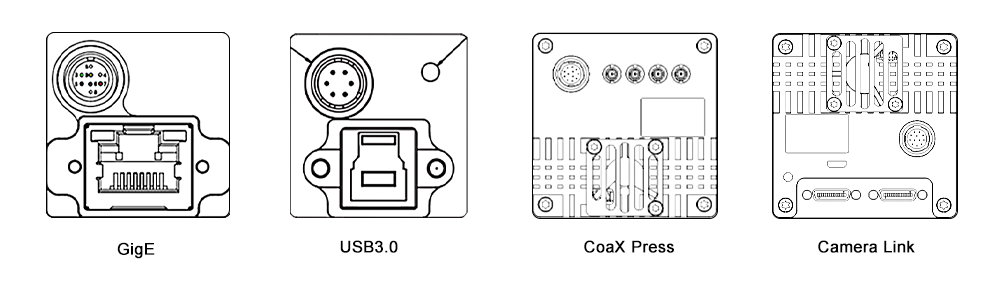

Industrial cameras support high-speed data interfaces tailored for real-time processing. Common interfaces include Gigabit Ethernet (1 Gb/s) and USB 3.0 (3 Gb/s), while advanced options like CoaXPress or Camera Link achieve even faster transfer rates. These interfaces enable seamless integration with industrial computers and vision systems, ensuring minimal latency during quality inspections. In contrast, consumer cameras typically rely on standard USB 2.0 or Wi-Fi connections, which are slower and less reliable for transmitting large volumes of image data.

4. Image Accuracy and Consistency

Industrial cameras prioritize precision and repeatability over aesthetic enhancements. They use high-quality sensors and specialized algorithms to eliminate distortions, ensuring images reflect the true state of objects—a critical requirement for defect detection or measurement tasks. Consumer cameras, however, often apply automatic adjustments (e.g., color saturation, noise reduction) that compromise data integrity for visual appeal. For example, a smartphone camera might smooth out surface imperfections on a product, whereas an industrial camera would highlight them for analysis.

Conclusion

The choice between industrial and consumer cameras hinges on the application's demands. For high-speed production lines, rigorous quality control, or harsh environments, industrial cameras are unparalleled in their speed, durability, and precision. Their ability to deliver reliable, real-time data makes them essential for modern manufacturing and automation. In contrast, consumer cameras remain suitable for everyday photography but fall short in meeting the technical and operational challenges of industrial settings. As the backbone of machine vision, selecting the right camera ensures both efficiency and accuracy in visual inspection systems.