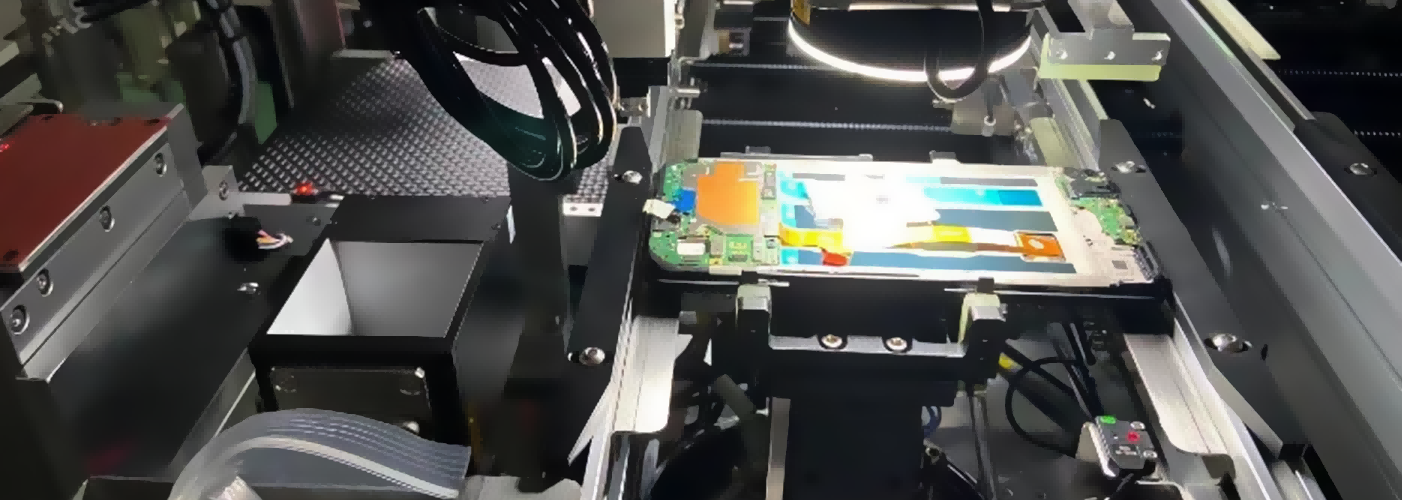

Why Do Machine Vision Projects Frequently Make Misjudgments?

Machine vision technology is an indispensable part of modern industry. With its continuous development, it has greatly facilitated product inspection on production lines. But have you ever encountered such a problem? Everything is set up step by step, yet the machine vision system frequently makes misjudgments! Products that are actually fine are mistakenly identified as defective, throwing the entire production line into disarray.

1. Product "Flaws" Are the Hidden Cause of Misjudgments

First, to solve the problem of misjudgments, we must start with the product itself. Think about it: if the product itself has dirt, flaws, or uneven surfaces, the machine vision system will be confused by these interfering factors. For example, dust, oil stains, or minor scratches on the product surface can cause the system to misjudge them as defects, leading to inaccurate inspection results. What’s the solution? The answer is to optimize the production process! Ensure that every product remains clean and flawless during production, minimizing the impact of any external factors on the inspection system. The cleanliness of the production environment directly affects the final inspection results—cleanliness is the guarantee of quality!

2. Cluttered Background? Misjudgments Start Here!

Apart from the product itself, another common cause of misjudgments is an unstable background. If the product’s background is cluttered or the lighting is unstable, the machine vision system can easily be led astray by these factors. For instance, inconsistent product placement, significant changes in light source, or unstable background features can all affect the system’s recognition capability. We know that manual inspection faces similar challenges—if product shapes and backgrounds vary greatly, even humans can make misjudgments, let alone machine vision! To solve this problem, maintaining background consistency is key! During production, strive to ensure that products are placed in the same position with a stable background to avoid misjudgments caused by background variations.

3. Overexposure and Excessive Gain Directly Reduce Image Quality

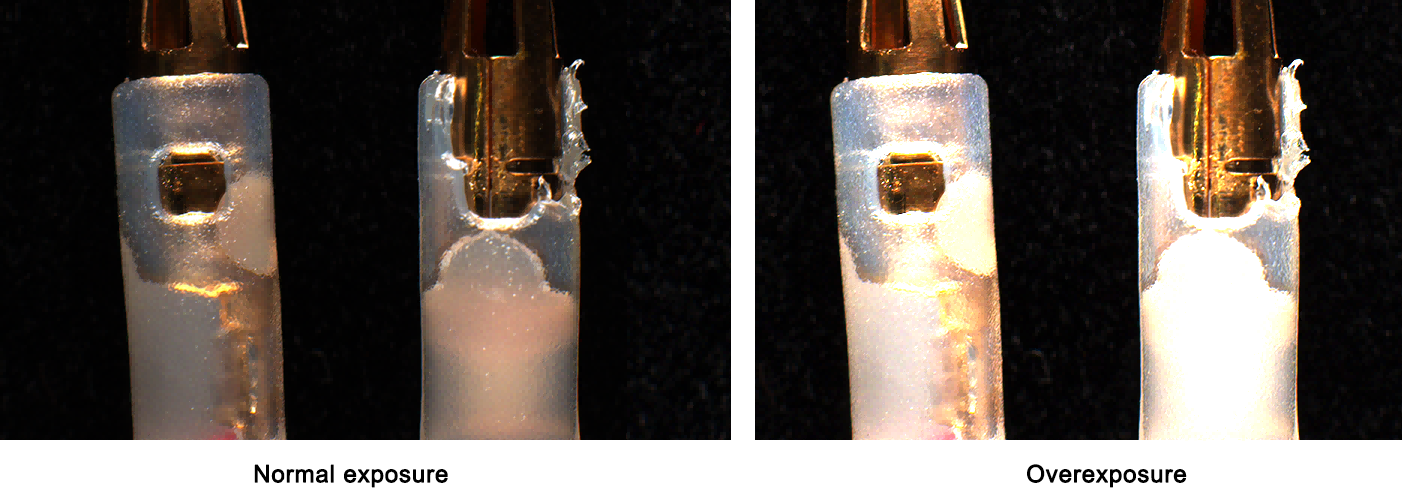

After addressing product and background issues, the next step is to examine image quality. The quality of the image directly determines the accuracy of visual inspection. Common problems include:

Overexposure: If the exposure time is too long, the image will appear washed out, losing details.

Excessive Gain: Too much gain increases image noise, reducing clarity.

Lens Distortion: Lens distortion can cause deformations at the edges of the image, affecting detection accuracy.

Don’t underestimate these image issues—they can lead to misjudgments by the machine vision system. Therefore, properly adjusting exposure and gain to ensure image clarity and stability is crucial! Additionally, lens selection is critical. Using high-quality lenses and applying distortion correction can significantly improve image precision.

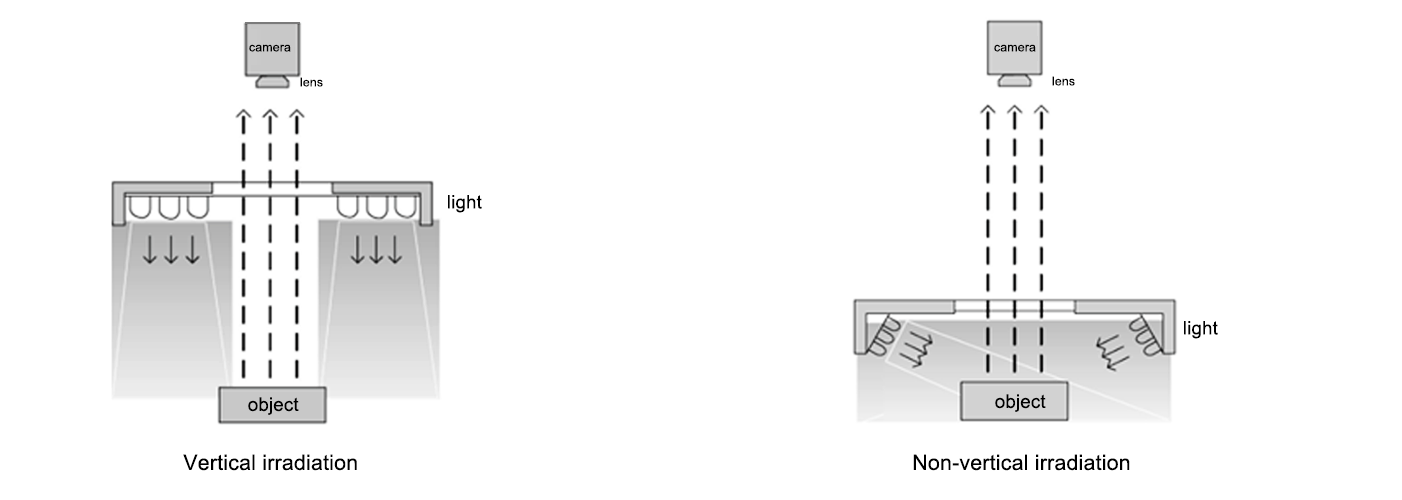

4. Lighting Issues: Strong Direct Light Is the Culprit Behind Misjudgments

Lighting problems cannot be overlooked in vision projects. You might not realize how much unstable lighting affects inspection results. Particularly, direct strong external light can easily cause overexposure, reduce contrast, and even impact the capture of image details. The best way to avoid this problem is to prevent strong direct light from shining on the product. If strong light is unavoidable, consider using shades, soft light sources, or other means to ensure stable lighting during imaging. This is extremely important because the stability of the vision system often depends on the quality of the light!

5. Choosing the Right Software

Beyond hardware and image-related issues, software is also a major hidden cause of misjudgments in machine vision. Some low-quality or free software platforms are often unstable and lack comprehensive features, directly impacting inspection accuracy and efficiency. An excellent vision software can accurately process image information and provide more stable and reliable detection results. Therefore, choosing a reliable and proven software platform is crucial—never compromise on software quality to save costs! Remember, truly useful software is worth the investment, as it provides stable support for your vision projects.

6. Regular Maintenance and Lens Cleaning: upkeep Cannot Be Neglected

Many people overlook an important detail: regular maintenance! The performance of a machine vision system depends not only on its inherent capabilities but also on daily upkeep. If dust or stains accumulate on the lens, the image will become blurry, affecting detection accuracy. Therefore, regularly cleaning the lens and checking the system status are essential tasks. Through proper equipment maintenance, you can not only extend the device’s lifespan but also reduce the likelihood of misjudgments.

In summary, the causes of misjudgments in machine vision are numerous—from product defects to image quality, lighting control, software selection, and daily maintenance. Negligence in any of these areas can lead to misjudgments. To avoid these problems, we must not only make technical adjustments but also focus on aspects like the production environment and product design, ensuring excellence in every step.