Working Principle of Liquid Lenses and Differences from Conventional Lenses

Liquid lenses are designed based on bionic principles, exhibiting remarkable similarities to the human eye's crystalline lens. Just as the human eye relies on ciliary muscles to control the refractive power of its lens for focusing, liquid lenses function by encapsulating optical fluid within an elastic polymer membrane. When an electric current is applied, it generates pressure within this sealed system, thereby altering the membrane's curvature and achieving near-instantaneous focus adjustment.

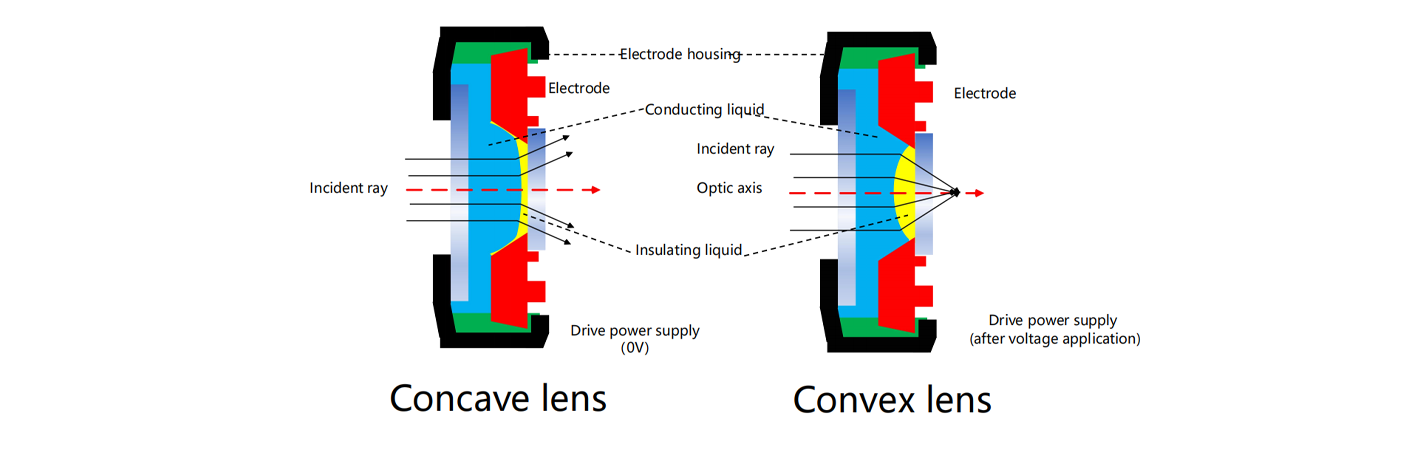

One prevalent manufacturing technique for liquid lenses is known as "electrowetting." This method requires two immiscible liquids – much like oil and water. When these liquids come into contact, the curved interface formed between them serves as an optical element, effectively acting as a lens. By applying an electrical current, we modify the radius of this optical interface (through increased electrostatic pressure), consequently changing the curvature of the "lens."

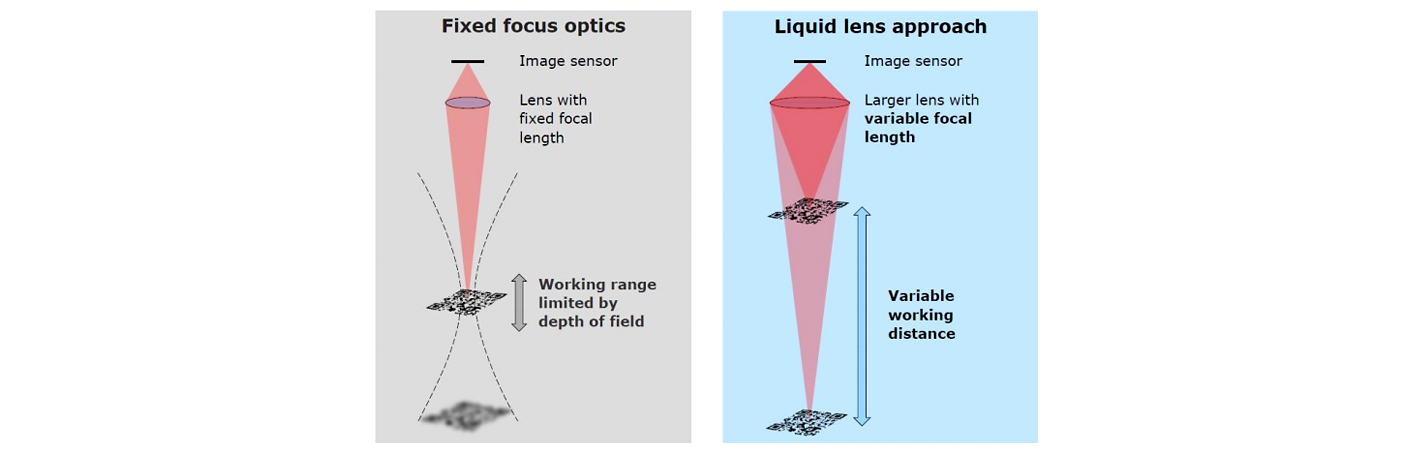

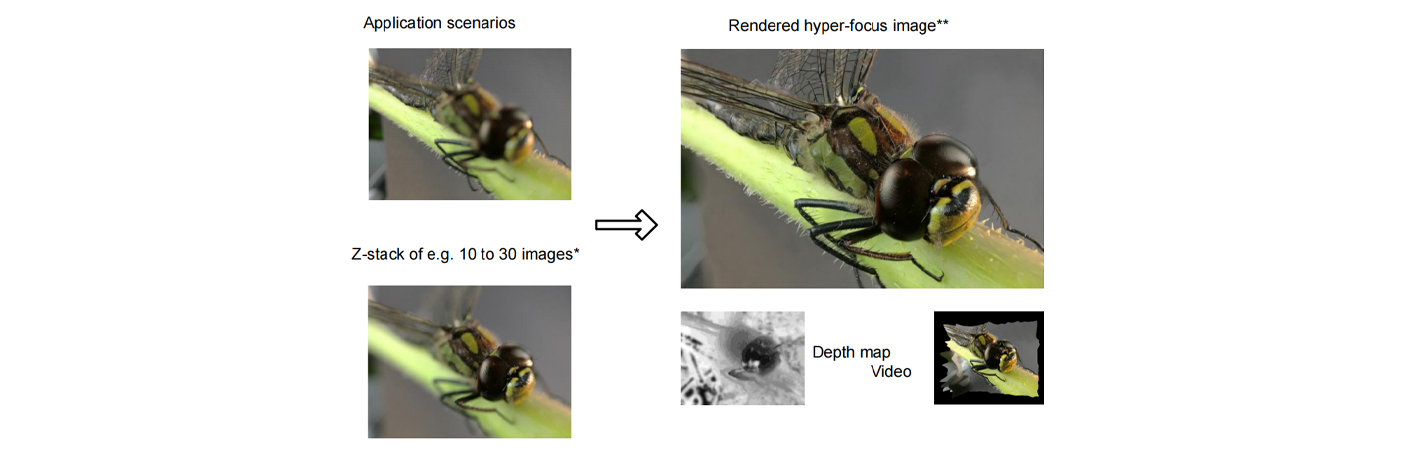

Furthermore, higher applied voltages generate greater curvature, directly modifying the lens's focal length. Remarkably, liquid lenses (sometimes called electrically tunable or "smart" lenses) can even transition between convex and concave configurations. This rapid adaptability makes them exceptionally valuable across diverse applications. Capable of focusing from extremely close objects to infinity within mere milliseconds, they prove ideal for scenarios requiring continuous distance adjustments. For instance, when inspecting objects of varying sizes or at different distances from the lens, liquid lenses demonstrate unparalleled versatility.

Compared to traditional lenses, liquid lenses offer the following distinct advantages:

Focusing Speed:

Liquid lenses: Achieve rapid autofocus with millisecond-level response times, mimicking the human eye's adaptability to changing scenes and distances. They excel in high-speed applications such as capturing fast-moving objects or industrial imaging on production lines, delivering near 100% successful image capture rates.

Conventional lenses: Depend on mechanical components (e.g., motors and gears) to physically shift lens elements for focus adjustment. Their focusing speed is comparatively slower, particularly during continuous autofocus or rapid zoom operations. Mechanical wear over time may lead to focus inaccuracies and degraded imaging performance.

Zoom Mechanism Design:

Liquid lenses: Adjust focal length by reshaping internal fluid or modulating pressure – requiring no physical displacement of components. This enables broader zoom ranges and facilitates high-magnification optical zoom. Precise focal length control is achieved through voltage regulation.

Conventional lenses: Utilize multi-element lens groups that mechanically shift along optical paths. This complex architecture introduces structural limitations, constraining zoom range and precision while increasing design intricacy.

Space Efficiency:

Liquid lenses: Feature inherently simpler structures without bulky mechanical assemblies, resulting in significantly smaller footprints. This advantage proves crucial for slim-profile electronics like smartphones and tablets, minimizing camera protrusion and enabling sleeker industrial designs.

Conventional lenses: Require substantial space due to multiple optical elements and mechanical drives, making them impractical for space-constrained applications.

Durability and Reliability:

Liquid lenses: Eliminate mechanical wear entirely since focusing relies on fluid dynamics. Consequently, they offer extended operational lifespans while maintaining consistent stability and reliability throughout prolonged use.

Conventional lenses: Suffer from inevitable mechanical degradation (wear, loosening) over time, necessitating periodic maintenance to preserve optical performance and prevent premature failure.

Manufacturing Costs:

Liquid lenses: Simplify production by eliminating precision machining and complex assembly processes. Utilizing economical materials like optical fluids further reduces costs, especially during mass production.

Conventional lenses: Demand high-precision manufacturing techniques and costly materials (specialty optical glass/plastics). Their intricate construction substantially increases production complexity and expense.

Optical Performance:

Liquid lenses: Enable dynamic tuning of refractive indices and dispersion characteristics in optical fluids. This adaptability delivers superior optical properties including enhanced light transmission and ultra-low dispersion, ultimately elevating image quality.

Conventional lenses: Possess fixed optical properties determined during manufacturing. Once lens materials and curvatures are finalized, their dispersion behavior and light transmission capabilities remain immutable.

The above are the all differences between liquid lenses and ordinary lenses. Looking forward to your like.