Machine Vision Camera Guide: How to Choose the Right Camera for Industrial Inspection

Core Machine Vision Camera Specifications That Drive Inspection Accuracy

Resolution and Pixel Size: Balancing Detail Capture with Field-of-View and Lens Constraints

Better resolution lets inspectors spot tiny flaws as small as 1.5 microns, which matters a lot when checking if PCB pads line up properly. These days, sensors with over 20 megapixels can catch problems that would go unnoticed by cameras with lower resolution. But there's always a catch when it comes to resolution. Bigger pixels ranging from about 3.45 to 9 microns actually help cameras gather more light, but they come at the cost of reduced detail clarity. And then there's the whole question of how much area needs to be viewed at once, which directly affects what kind of sensor and lenses work best together. Many people make the mistake of slapping a fancy high-megapixel sensor onto a cheap or too-small lens, and suddenly the lens becomes the weak link instead of the camera itself. When looking at large inspection areas, nobody gets good results just by focusing on one component alone. The whole system needs to work together right from the start.

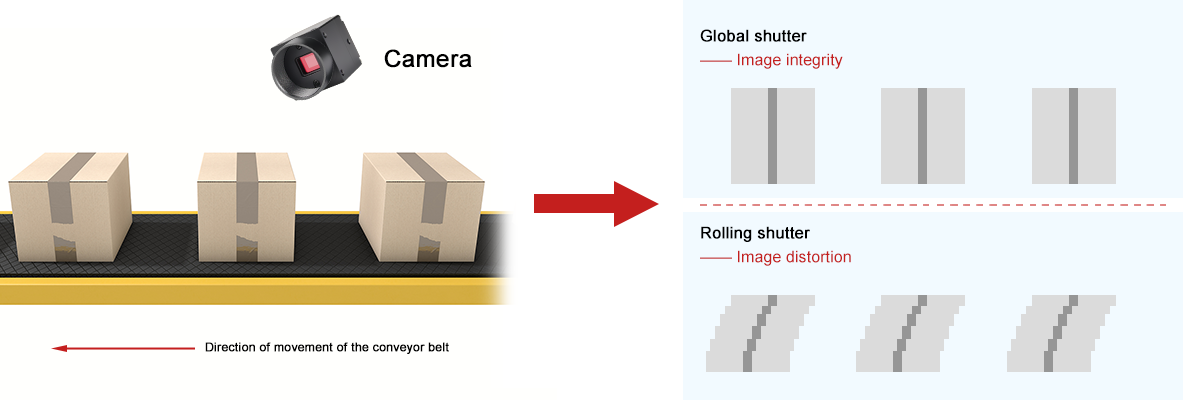

Frame Rate and Shutter Type: Eliminating Motion Blur in High-Speed Production Lines

For distortion free imaging on those high speed conveyor belts running at 5 meters per second or quicker, global shutters become a must have solution since they capture whole frames at once. Rolling shutters just can't keep up with fast moving items and tend to create skewed images. When it comes down to calculating what frame rate we need, basically take the speed of the parts moving past divided by how small a flaw needs to be detected. Let's say someone wants to spot defects as tiny as 0.1 millimeters while things move along at 3 meters per second. That math works out to needing at least 300 frames per second minimum. Manufacturing lines processing around 20 thousand products every hour typically demand over 500 fps with exposure times measured in microseconds to stop motion dead during important checks. Think about stuff like making sure bottle caps thread properly or tracking weld seams accurately. Getting the position right matters because even slight misalignment can mean the difference between catching a defect and missing it completely.

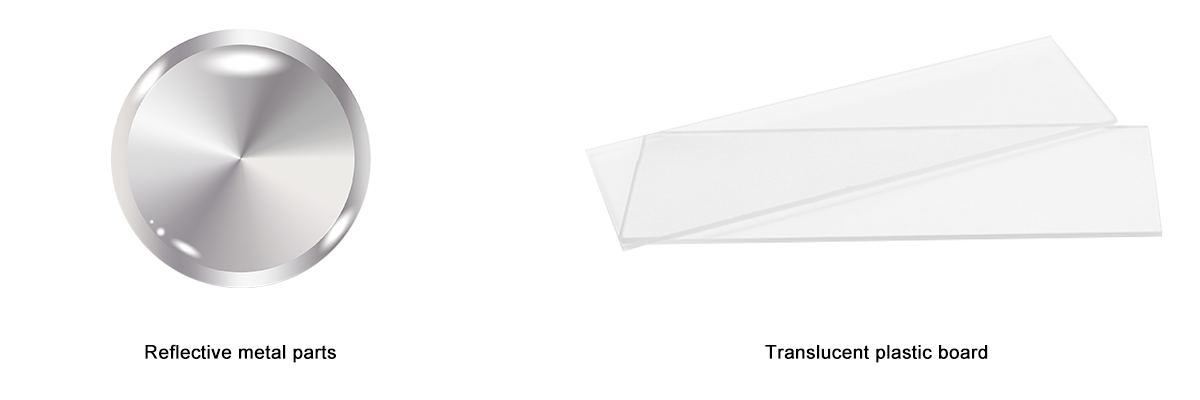

Dynamic Range and Quantum Efficiency: Maximizing Contrast and Low-Light Sensitivity for Defect Detection

Cameras boasting at least 120 dB dynamic range can capture those tricky reflectivity differences we often miss - think about how they handle polished metal versus backlit clear plastics without blowing out highlights or drowning in shadow noise. When paired with sensors that have over 80% quantum efficiency (something possible with back-illuminated CMOS tech), these cameras work surprisingly well in dim conditions without all that grainy mess from cranking up the gain. The real magic happens when looking at composite materials for hidden flaws. Small changes in how light gets absorbed point to voids inside the material. Automotive manufacturers find this particularly useful too. They need to spot tiny cosmetic issues on car paints, sometimes as small as 5% difference in reflectivity, even when factory lights flicker or change intensity during production runs.

Matching Machine Vision Camera Sensor Technology to Material and Wavelength Requirements

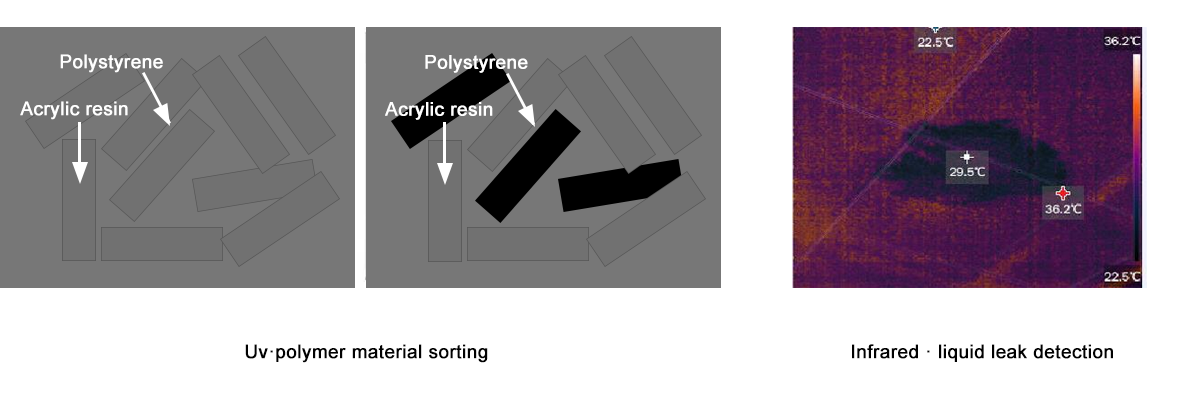

Visible, UV, and SWIR Sensors: When Subsurface Defects Demand Beyond-Visible Spectrum Imaging

Regular visible light sensors work great for checking surfaces but fall short when it comes to seeing what's hidden beneath materials like plastic, composite parts, or silicon components. UV sensors in the 200 to 400 nm range pick up on tiny cracks and glowing substances by exciting the materials they scan. Meanwhile, those Short Wave Infrared sensors operating between 900 and 2500 nm wavelengths can actually see through opaque plastics and silicon wafers to spot problems like water getting inside, layers separating, or temperature variations that might cause issues later. Research published last year showed these SWIR sensors found nearly 40% more hidden defects in medicine packaging compared to standard lighting methods. The bottom line is that aligning the sensor's wavelength with how different materials absorb light makes all the difference in catching serious problems before they become big headaches.

Monochrome vs. Color Sensors: Tradeoffs in Sensitivity, Speed, and Spectral Fidelity for Industrial QA

Black and white sensors typically offer about 60 percent better quantum efficiency compared to their color counterparts because they don't have those Bayer filters that absorb light. This means they can capture images faster and work much better in dim lighting conditions. These advantages make them ideal for spotting subtle scratches on metal surfaces or tiny defects in fast moving bottling operations. Color sensors only really come into play when actual color matters for quality checks, like making sure pills have consistent coatings or car paints look right across different panels. But there's a catch with color sensors too. Their demosaicing process adds delays and actually lowers both resolution and sensitivity in practice. Many facilities end up seeing more false rejects as a result. For most inspection tasks where color doesn't matter, sticking with monochrome setups keeps things accurate in shades of gray while boosting overall inspection speed and reducing errors.

Area Scan vs. Line Scan Machine Vision Cameras: Selecting by Part Geometry and Motion Profile

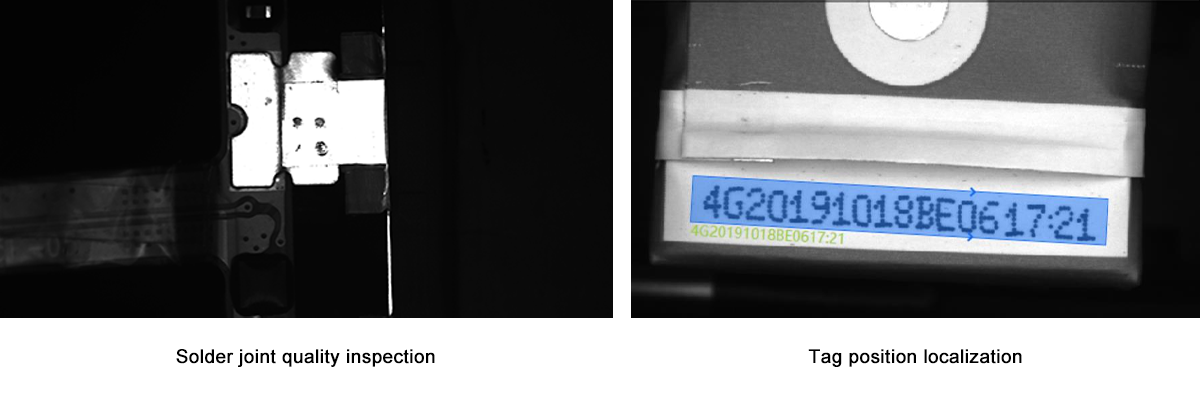

When to Choose Area Scan: Stationary or Intermittent Parts with Complex 2D Features

Area scan cameras take complete images all at once, which makes them great for checking parts that don't move much or only move occasionally when detailed 2D analysis is needed. Think about things like inspecting solder joints on printed circuit boards, verifying labels are properly placed, or aligning components with multiple features. These cameras can check several different aspects in one shot, so they work well in batch production settings common in electronics manufacturing where short stops allow for clear imaging. Getting the timing right is still important though to prevent blurry images when parts do move around a bit between captures. But despite these limitations, area scan systems remain incredibly versatile for handling complicated shapes and irregular patterns that don't follow standard repetitive designs.

When to Choose Line Scan: Continuous Web, Conveyor, or Rotating Cylinder Inspection

Line scan cameras were specifically designed for applications where things keep moving non-stop, such as checking webs during production, fast conveyor belts, or round objects that spin around. These cameras can actually stop motion blur even when stuff moves faster than 5 meters per second. They work by matching the timing of their single row of pixels to how materials move along the production line, which creates clear pictures without any stretching or warping. This makes them great for inspecting long continuous products like paper rolls, metal sheets, and plastic films. Plus, they give complete views all around bottles and cans as they rotate. According to what most people in packaging know, these line scan setups cut down on data amounts by about 80 percent compared to regular area scan systems. And here's the kicker they still catch defects just as well without stopping the production process at all.

Industrial-Grade Connectivity and Environmental Hardening for Reliable Machine Vision Camera Deployment

Around 70 percent of problems with machine vision systems on factory floors actually come down to tough environmental factors. Think about it: extreme heat or cold, dust blowing around, constant vibrations from machinery, plus all that pesky electromagnetic interference. Industrial strength cameras fight back against these issues with special design features. They come with IP67 rated housing that keeps dirt and moisture out. The GigE Vision connections are shielded against EMI so data stays clean even when there's electrical noise everywhere. These cameras can handle serious shaking thanks to their reinforced mounts, and they work reliably across a wide temperature range from minus 30 degrees Celsius up to 70 degrees. That means they perform well whether installed next to blazing hot furnaces, inside freezing tunnels, or alongside big vibrating equipment. Plus there's built-in power backup to protect against sudden voltage changes. All these protections help keep production running smoothly without unexpected stops, maintaining quality checks throughout. Regular consumer grade cameras just wouldn't stand a chance in such demanding environments before breaking down completely.

Ready to Find Your Perfect Machine Vision Camera?

Don’t let subpar camera choices hold back your quality control. Contact HIFLY today for a free consultation—our team will help you match camera specs to your inspection needs, from resolution and frame rate to sensor type and environmental resistance. With custom solutions, fast delivery, and global support, we’re your partner in building reliable, efficient machine vision systems.