Machine Vision Camera Selection Tips for Factory Automation Engineers

Core Machine Vision Camera Selection Criteria for Industrial Reliability

Why Consumer Cameras Fail in Factory Environments

Consumer-grade cameras consistently underperform in industrial settings due to three critical vulnerabilities:

- Vibration sensitivity: Factory machinery generates 5–10 times more vibration than consumer environments, causing lens misalignment and focus drift

- Temperature limitations: Operating beyond 40°C accelerates sensor degradation—industrial testing shows a 78% failure rate at 60°C

- EMI susceptibility: Unshielded components introduce 42% more image artifacts near motors compared to purpose-built industrial cameras

These weaknesses directly contribute to the $740k average cost of unplanned manufacturing downtime (Ponemon Institute, 2023), underscoring why only purpose-engineered machine vision cameras deliver the reliability required for mission-critical automation.

Key Standards: EMVA 1288 for Performance Validation and ISO/IEC 15444-1 for Image Data Integrity

Machine vision cameras used in industrial settings rely on certain basic standards to maintain consistent performance and accurate data capture. Take the EMVA 1288 standard for example. This framework lets engineers measure important sensor characteristics like how well they capture light (quantum efficiency), background noise levels when no light is present (temporal dark noise), and variations in response across different parts of the sensor (photoresponse non-uniformity). These measurements help compare different camera models from various manufacturers side by side without bias toward any particular brand. Another key standard is ISO/IEC 15444-1 also known as JPEG 2000. This one ensures images can be compressed without losing quality, which matters a lot when transferring pictures at high speeds through factory automation systems. Maintaining every single pixel's detail is critical for spotting tiny defects in products during automated inspections. The combination of these standards helps achieve that near perfect 99.95% detection rate required in top tier automotive production lines and medical device factories where even minor flaws cannot be tolerated.

Matching Machine Vision Camera Design to Factory Constraints

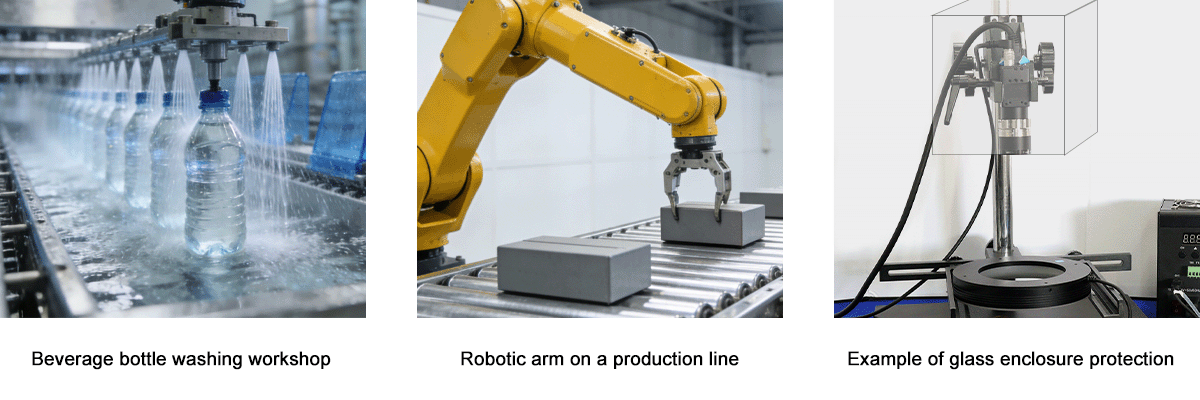

Environmental Hardening: IP67, M12, and Hermetic Sealing—When Each Is Required

Factory floors impose harsh, application-specific environmental stresses—requiring precise alignment between protection level and operational threat profile:

- IP67 provides complete dust ingress protection and withstands temporary immersion (up to 1m for 30 min), making it ideal for food & beverage washdown stations and wet-packaging lines

- M12 connectors, with threaded metal housings and robust locking mechanisms, maintain signal integrity under sustained mechanical vibration—critical for cameras mounted on high-speed conveyors or robotic arms moving at 1.5 m/s

- Hermetic sealing, achieved via welded metal housings or glass-metal feedthroughs, blocks corrosive gases (e.g., HF in etch processes) and sub-micron particulates—mandatory in semiconductor cleanrooms where 0.5µm contaminants trigger costly process excursions

Selecting mismatched protection accounts for 23% of premature camera failures. Match sealing rigor to risk: IP67 for splash zones, M12 for mobile or vibrating platforms, and hermetic for vacuum, plasma, or ultra-clean environments.

SWaP-C Optimization: Size, Weight, Power, and Cost in Embedded Automation Systems

When looking at embedded systems and mobile automation like AGVs, cobots, drones, and those inspection nodes mounted at the edges, SWaP-C (size, weight, power, and cost) limitations really determine whether something can be integrated successfully and what it will cost over time. Designs that stay below 50 grams help avoid problems with balance on robotic arms that accelerate quickly. Power efficient versions drawing less than 3 watts actually boost battery life for self-driving vehicles by about 18% per charge cycle. And when sensors and processors come together in one package, we see fewer parts needed overall, which cuts down on material costs around 30% without hurting performance. Going overboard on any aspect of SWaP-C tends to raise costs dramatically. For instance, putting in a fancy 12 megapixel camera when a simple 2MP version would work just fine adds between 15 to 40 percent extra expenses each year because of all the extra cooling, power conditioning, and processing requirements. The bottom line? Think about physics first when making decisions. Drones that need to move fast often sacrifice image quality for better maneuverability, whereas stationary inspection setups focus more on getting the most detailed images possible within their heat dissipation limits and available data transfer speeds.

Critical Machine Vision Camera Specifications and Their Real-World Impact

Resolution vs. Frame Rate Tradeoffs in High-Speed Inspection (e.g., PCB Solder Joint Analysis)

The balance between resolution and frame rate isn't just about what looks good on spec sheets—it's actually determined by how sensors read out data and the available system bandwidth. When looking at PCB solder joints, finding those tiny issues below 50 microns such as cold joints or bridging needs enough detail in each image. A 5 megapixel sensor running around 60 frames per second works best for most situations, capturing the necessary details without slowing down production lines too much. Cameras with lower resolution but higher frame rates (like 1 to 2 megapixels at 150 to 200 fps) are great for tracking movement but simply don't have enough pixels to measure small features accurately. On the flip side, those super high resolution sensors above 12 megapixels tend to struggle with speed unless connected through something fancy like CoaXPress 2.0 or 10 Gigabit Ethernet connections. Get either spec wrong and problems happen fast. Missed defects mean quality issues downstream while unnecessary stops waste time and money. The industry knows this costs companies roughly seven hundred forty thousand dollars every year in unexpected downtime across manufacturing facilities worldwide.

|

Camera Type |

Resolution |

Frame Rate |

Best For |

|

Detail-Oriented |

5MP+ |

30–60fps |

Micro-crack detection, solder joint analysis |

|

Speed-Oriented |

1–2MP |

150–200fps |

Real-time motion tracking, object counting |

Dynamic Range, Full Well Capacity, and Quantum Efficiency: What Actually Drives Low-Light Robustness

When it comes to performing well in low light conditions, there are actually three key sensor characteristics that matter most, not things like ISO settings or fancy software fixes. Let's start with dynamic range, or DR for short. This basically measures the difference between when a sensor gets saturated and its baseline noise level, usually expressed in decibels. A good DR means the camera can capture details in both very dark and very bright parts of a scene at the same time. Think about those situations where there's intense glare next to deep shadows, like what happens near shiny metal surfaces in manufacturing environments. Then we have quantum efficiency, which tells us what percentage of incoming light actually gets converted into usable electronic signals. The higher this number goes above around 65%, the better the image quality becomes in darker settings because the signal stands out more clearly against background noise. Full well capacity refers to how much electrical charge each pixel can hold before getting overwhelmed. Sensors with capacities over 15,000 electrons handle bright spots much better without losing detail or creating unwanted artifacts. Putting all these together makes a big difference. Cameras equipped with over 120dB of dynamic range, better than 65% quantum efficiency, and full well capacities exceeding 15,000 electrons can slash error rates by about 30% during warehouse checks when lighting is poor. Plus, facilities don't need to invest so heavily in costly lighting infrastructure that requires constant upkeep.

Global vs. Rolling Shutter: Clarifying Motion Artifacts in Automated Production Lines

The kind of shutter used makes all the difference when it comes to capturing accurate shapes in applications where motion matters. Global shutters work by exposing every pixel at once, which basically stops action dead in its tracks without any distortion. This matters a lot for things like measuring gears on car parts that zoom past at 30 meters per second or checking how pills rotate inside their packages. Rolling shutters tell a different story though. They scan image rows one after another, creating what's called time skew. What happens? Edges get warped, shapes bend strangely (think the dreaded jello effect), and lighting looks uneven on moving stuff. Try imaging something like a robotic arm spinning around or a conveyor belt going back and forth with a rolling shutter, and measurements could be off by over 2% - enough to mess up quality checks completely. Sure, rolling shutters save money and power for stuff that doesn't move much, but when fractions of a millimeter count during inspections, there's really no substitute for global shutters. They keep quality control consistent and avoid those expensive mistakes that come from bad readings.

Ready to Choose the Right Machine Vision Camera?

Factory automation success hinges on aligning camera design, specs, and standards with your unique constraints—from environmental rigor to inspection speed. By avoiding consumer-grade cameras, validating against EMVA 1288/ISO standards, and balancing key specs, you’ll unlock reliable, consistent performance.

For personalized guidance or to test a tailored solution (backed by 3–7 day sample delivery and global technical support), partner with a trusted provider with a track record in industrial automation. HIFLY’s 15 years of expertise and custom solutions ensure your camera works as hard as your factory does.