Machine Vision Camera vs. Industrial Camera: Key Differences Explained

What Defines a Machine Vision Camera?

Core Technical Requirements: Global Shutter, Trigger Precision, and SDK-Driven Integration

Industrial machine vision cameras aren't just built to last they need to deliver consistent results every single time. What makes these cameras stand out? Well, they use something called global shutter tech which grabs all image data at once, so there's no motion blur even when objects move faster than 5 meters per second. Another key feature is hardware triggering that works down to the microsecond level, making sure everything lines up perfectly with robot movements or conveyor belt actions. And thanks to SDK integration through GenICam standards, these cameras play nice with most PLC systems and vision software packages. The result? Companies can get their quality control systems up and running much quicker without having to write custom drivers from scratch, saving roughly two thirds of what would normally be spent on deployment time according to industry reports.

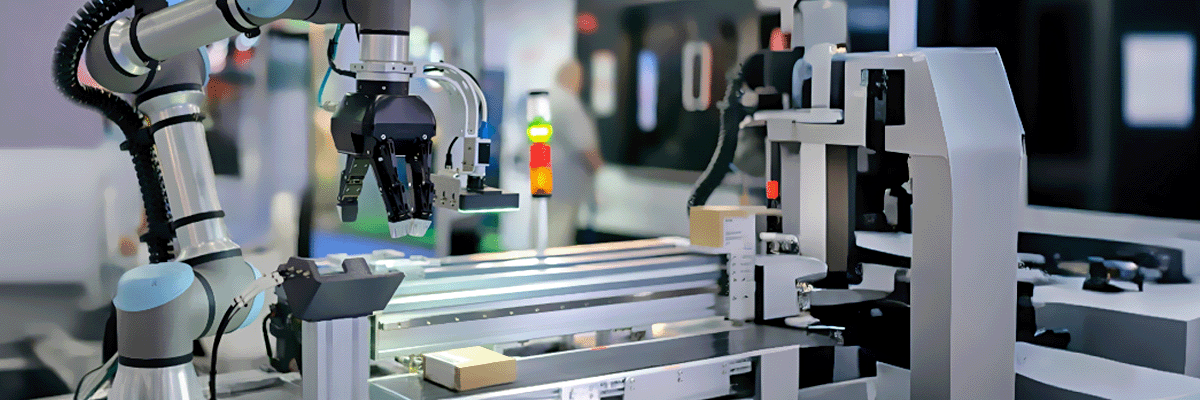

Primary Applications: Automated Optical Inspection, Robot Guidance, and Sub-Pixel Metrology

The technical specs of these systems open doors to three really important applications in manufacturing. When it comes to Automated Optical Inspection or AOI work, those high res global shutter sensors can spot tiny flaws on printed circuit boards down to almost perfect 99.9% detection rates. Talking about robot guidance now, the real time 3D pose estimation allows machines to place components with incredible consistency, around plus or minus 0.05mm accuracy during pick and place operations. Then there's sub pixel metrology which takes calibrated sensors and some fancy math to see details even smaller than what fits in a single pixel. This matters a lot for aligning semiconductor wafers where manufacturers need tolerances under one micrometer. What makes all this possible? These camera systems approach imaging as serious measurement rather than simple picture taking, which explains why they deliver such remarkable results across different industrial settings.

What Qualifies as an Industrial Camera?

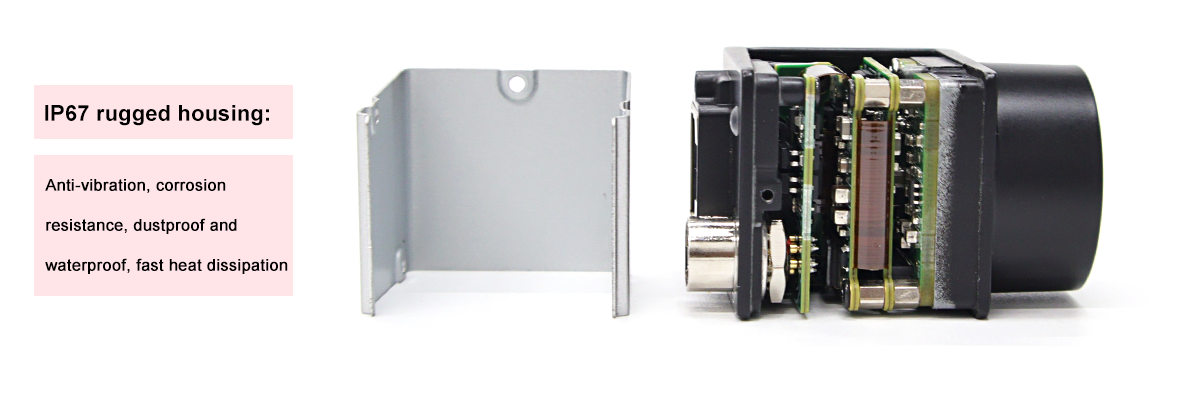

Design Priorities: Rugged Housing, Extended Temperature Range, and IP67+ Environmental Sealing

When it comes to industrial cameras, manufacturers tend to focus more on keeping them running reliably than capturing perfect images. These cameras typically come with tough exteriors made from either metal or reinforced plastic that can handle rough handling, constant vibrations, and even harsh chemicals without breaking down. Most models work across a wide temperature range from minus 20 degrees Celsius all the way up to 70 degrees, plus they usually meet IP67 standards or better against dust and water intrusion. This makes them suitable for environments like food processing plants where regular cleaning happens, cold storage facilities, or anywhere outdoors needs monitoring. Design features such as passive cooling systems, straightforward connectors like those M12 types, and simpler firmware help these cameras stay online longer. But there's always something given up in return for this reliability - things like sophisticated triggering options, fast data transfers, or fine-tuned sensor adjustments often take a back seat when building for durability first.

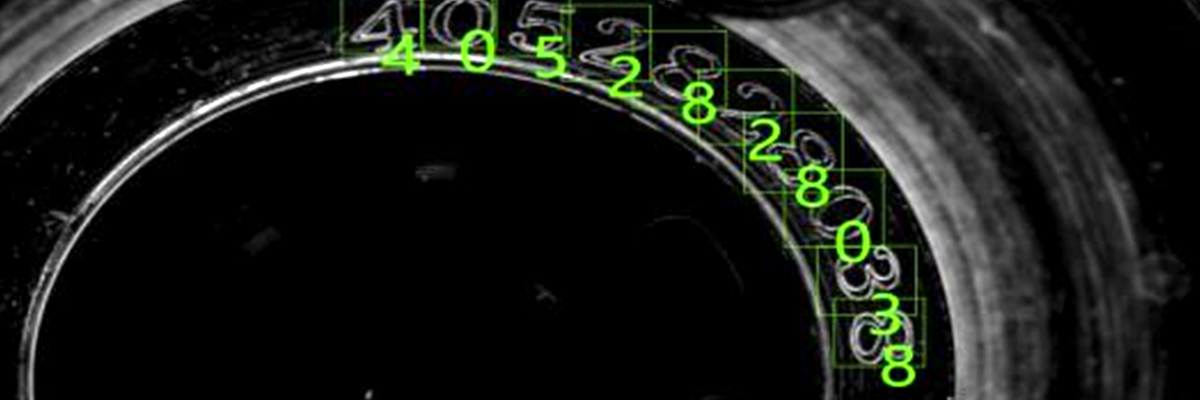

Typical Use Cases: Continuous Process Monitoring, Basic OCR, and Harsh-Environment Surveillance

What these cameras really shine at is situations where having continuous coverage matters more than getting every pixel right. Think about things like keeping an eye on tank levels all day long, checking if conveyors are still working properly, or just making sure machines aren't breaking down. They also handle basic OCR tasks for reading serial numbers or sorting packages. And let's not forget those tough spots where regular cameras wouldn't last a minute, like deep inside mining operations or around all that corrosive stuff in wastewater treatment facilities. According to a recent industry report from 2023, most plant managers actually put environmental toughness above picture quality when it comes to these applications. Makes sense really, because what good is crystal clear footage if the camera dies after a week in harsh conditions? For real world operations, dependable performance trumps fancy specs any day.

Critical Functional Differences: Automation, Performance, and Integration

Real-Time Control & Synchronization: Hardware Triggering, Frame Grabbers, and Deterministic Latency

Deterministic timing is what makes machine vision cameras so essential for closed loop automation systems. These cameras use hardware triggers to sync their exposure with outside signals like encoder pulses or PLC outputs down to fractions of a microsecond. Pair them with frame grabbers and suddenly we're talking about image transfer times under a millisecond consistently. Software triggered cameras? They get stuck waiting on the operating system to schedule tasks, leading to those annoying 10-50ms delays everyone hates (Vision Systems Design reported this back in 2023). Imagine running a conveyor belt at 1 meter per second. Five milliseconds of delay equals five whole millimeters off track - enough to mess up even the most delicate assembly work. That's why serious machine vision setups rely on dedicated imaging pipelines and real time operating systems from day one. No room for guesswork when precision matters.

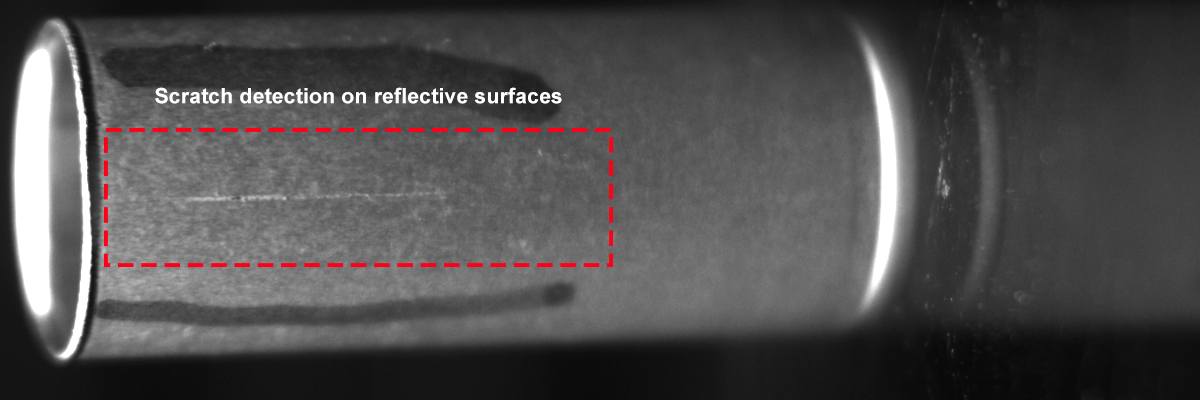

Imaging Performance Benchmarks: Dynamic Range, SNR, and Pixel-Level Consistency for Measurement

Getting accurate measurements requires imaging systems designed specifically for precision rather than just approximations. Modern machine vision cameras deliver over 120 dB dynamic range, which means they can capture both the subtle details in dark areas of matte black rubber while still picking up bright reflections off chrome surfaces at the same time. These cameras typically have signal-to-noise ratios between 40 and 50 dB, maintaining good contrast and sharp edges during inspections in dim lighting conditions. This beats standard industrial cameras that usually fall below 35 dB, where background noise starts to mess up dimensional measurements. Factory calibration makes sure these sensors stay within about 0.05% variation across all pixels, something essential for those ultra precise sub-pixel measurements. Looking at automated optical inspection systems, studies show that just 2% inconsistency in sensor response leads to false rejects worth around $740,000 per year according to Ponemon Institute research from 2023. That's why true measurement grade equipment stands apart from regular industrial cameras when it comes to consistent results.

Why the Terminology Confusion Exists—and How to Choose Correctly

There's a lot of crossover between machine vision and industrial camera labels because they both tend to be built tough. Manufacturers frequently mention things like IP67 protection and operation across extreme temperatures. But looking past these similarities reveals what really matters. Industrial cameras are basically designed to survive harsh conditions while machine vision models focus on getting precise measurements for automated processes. The problem comes when companies try to use industrial grade equipment for jobs that need pinpoint accuracy down to fractions of a pixel or synchronized timing in millionths of a second. These requirements just aren't part of industrial cameras' design DNA.

To choose correctly:

- Prioritize application demands: Select a machine vision camera if your use case requires global shutter, hardware triggering under 1µs, or GenICam-compliant SDK integration—for AOI, robot guidance, or metrology. These are not optional features—they’re foundational.

- Assess environmental needs: Choose an industrial camera only for continuous monitoring, basic OCR, or surveillance in harsh settings—where shock resistance, washdown tolerance, or 24/7 uptime outweigh imaging precision.

- Evaluate integration complexity: Machine vision systems require certified drivers, frame grabber compatibility, and deterministic communication with PLCs or vision software. Industrial cameras typically operate as standalone video sources.

- Scrutinize performance thresholds: For quantitative inspection, insist on ≥70dB dynamic range, SNR >40dB, and pixel uniformity <0.1%. These benchmarks are rarely met by industrial models marketed for vision tasks.

Match the camera to your automation’s precision, speed, and integration depth—not just its housing rating.

Ready to Align Your Camera with Your Workflow?

The right camera turns industrial imaging from a cost center into a competitive advantage—whether you’re automating precision inspections or monitoring harsh environments. By focusing on your core needs (automation precision vs. rugged reliability), you’ll avoid common pitfalls and unlock consistent results.

For personalized guidance or to test a tailored solution (backed by global technical support and fast sample delivery), reach out to a trusted machine vision partner with a track record of serving diverse industrial sectors.