Best Machine Vision Camera Solutions for Automated Quality Control

Why Machine Vision Camera Performance Dictates Inspection Accuracy

Resolution and Pixel Density: Detecting Sub-Millimeter Defects at Production Speed

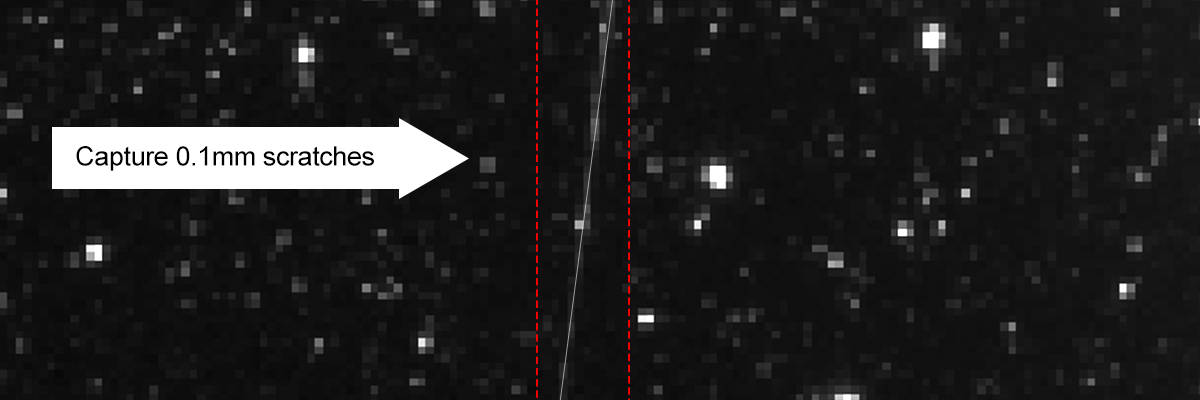

Better resolution means we can spot those tiny defects that are smaller than a millimeter, sometimes as small as 1.5 micrometers, because there are simply more pixels packed into the sensor area. But just having high resolution doesn't cut it on its own. For AI inspections to work best, the features being looked at need to cover about 5 to 10 pixels. This creates the sweet spot where enough detail gets captured without slowing things down too much during processing. Going beyond this range just makes the data pile up faster without really improving our ability to tell good parts from bad ones, and that can actually slow production lines. Today's global shutter CMOS sensors hit this sweet spot pretty well, managing to identify defects with around 99% accuracy while still keeping up with processing hundreds of items every single minute. What matters most isn't necessarily how many megapixels the camera has, but getting the right number of pixels for both the tiniest details we need to see and how fast the assembly line moves.

Frame Rate & Trigger Synchronization: Eliminating Motion Blur in High-Speed Lines

Motion blur still causes most missed defects on those fast production lines, even when companies install those fancy ultra high res sensors. When the line is running over 1,000 parts per hour, the camera needs to capture each item in less than 20 milliseconds just to keep the edges sharp enough. That's where encoder synced global shutter cameras come in handy. These cameras lock the exposure time right to where the part is on the conveyor belt, which keeps detection rates around 98.5% even at top speed. The difference is huge compared to older systems without synchronization. Factories in auto manufacturing and electronics assembly see about an 80% drop in false alarms when they upgrade. Makes sense too, since these industries work with components measured in microns, so there's literally no room for guesswork or mistakes.

Comparing Leading Machine Vision Camera Platforms for Industrial Inspection

Basler ace 2 vs. FLIR Blackfly S: Real-World Benchmarking on Precision, Stability, and SDK Support

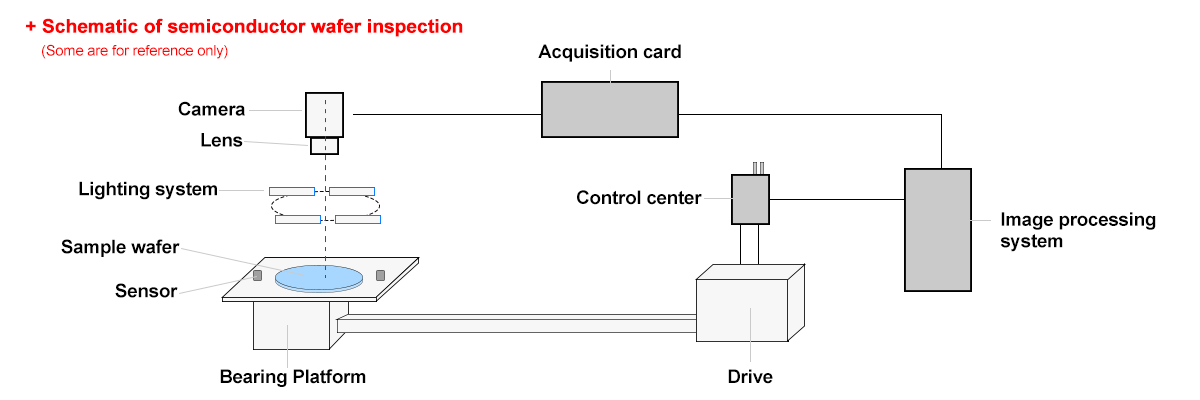

The Basler Ace 2 series makes use of those great Sony Pregius sensors which actually manage to get measurement repeatability down to less than 0.1 pixel even when there's all sorts of industrial vibrations going on around them. Plus these cameras maintain pretty impressive gain stability too, staying within plus or minus 0.05 percent despite temperature changes of up to 15 degrees Celsius. What really stands out is their Pylon SDK that works so well with robotic arms and PLC networks, which makes them absolutely perfect for those fast moving production lines running over 200 frames per second. On the other hand, FLIR's Blackfly S models have their own tricks up their sleeve with proprietary image processing that cuts motion artifacts by roughly 40% on those super fast conveyors. And let's not forget about the Spinnaker SDK that supports multiple programming languages including Python, C# and .NET. Both camera systems handle inspection tasks for semiconductor wafers and electric vehicle battery parts without issues, but where they differ is in specific conditions. Basler tends to perform better in terms of thermal and mechanical stability when deployed at larger scales, while FLIR shines in situations where lighting is extremely dim, delivering excellent results even at light levels below 0.1 lux.

Smart Cameras (Cognex Insight, Keyence CV-X) vs. PC-Based Machine Vision Camera Systems

Smart cameras from brands like Cognex Insight and Keyence CV-X really speed things up. For simple dimensional checks, these devices can be running in just under two days because they come with built-in processors and already have common defect patterns programmed in. Plus, they save about 30% on wiring expenses when used alone in workstations, which is great news for factories where every inch counts. On the other side of things, computer systems connected to powerful GPU servers give manufacturers roughly five times more processing power for tougher jobs such as identifying subtle surface flaws, measuring objects from multiple angles in three dimensions, or adjusting models while operations are still running. These setups let companies manage over fifty different products at once across networks with multiple cameras something that becomes absolutely essential when dealing with diverse manufacturing runs. Sure, smart cameras make it easier to get started with quality control, but computer based systems simply cannot be beat when it comes to growing alongside business needs, adapting algorithms quickly, and handling serious computation demands.

How to Select the Right Machine Vision Camera for Your Quality Control Application

A Practical Decision Framework: Aligning Camera Specs with Product Tolerance, Line Speed, and Lighting Constraints

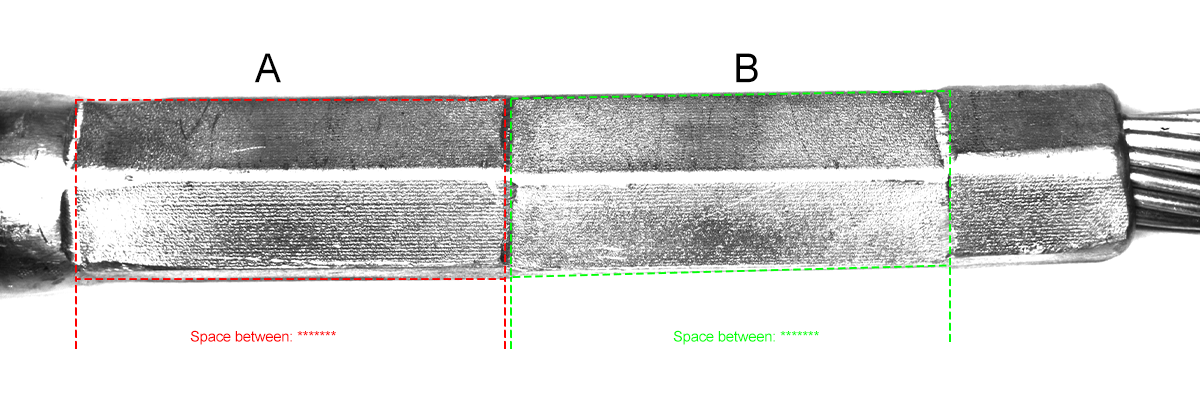

When looking at defect detection, begin with the smallest flaw you need to catch. Take that dimension, say something like a 0.1 mm scratch, and then divide it by what the industry suggests as 3 to 4 pixels per feature. That gives us a baseline for resolution needs. Moving on to conveyor speeds matters too. If things are zipping along faster than 1 meter per second, we really need those global shutter sensors working with frame rates above 120 fps. And when production hits over 200 items per minute mark, exposure time has to stay under half a millisecond otherwise everything gets blurry. Lighting conditions present another challenge altogether. In dim settings, look for cameras with quantum efficiency better than 75% and dynamic range exceeding 70 dB so images maintain their contrast and clarity. Following this approach across three k在· ey areas helps ensure cameras actually find those tiny flaws in practice, not just on paper specs. It keeps costs reasonable without sacrificing what works on the factory floor day after day.

Ready to Elevate Your Automated Quality Control?

Don’t settle for off-the-shelf cameras that miss critical flaws or slow your line. HIFLY’s custom machine vision camera solutions are engineered to your exact QC needs—whether you’re detecting 1.5μm defects, inspecting 200+ parts per minute, or operating in harsh environments.

Contact HIFLY today for a free consultation: our team will assess your workflow, recommend specs, and deliver a custom sample in as little as 3 days. Let’s build a QC system that scales with your business and delivers 99%+ defect detection accuracy—every time.