Streamlining Industrial Automation Through High-Resolution Machine Vision Cameras

The Role of High-Resolution Cameras in Industrial Automation

Enhancing Precision with 25+ Megapixel Imaging

High-resolution cameras with 25+ megapixel sensors play a crucial role in enhancing precision imaging within industrial automation. These cameras offer exceptional image clarity, enabling detailed inspections at the micro-level — a necessary feature for industries like electronics and pharmaceuticals that demand meticulous quality control. By significantly reducing image noise and maintaining integrity under varied conditions, high-resolution cameras are specifically tailored for challenging industrial environments. Their high pixel count empowers the detection of minute details crucial for maintaining product quality standards across various sectors.

Moreover, sectors prioritize these cameras because they efficiently capture critical factors — facilitating improved inspection processes. For instance, machine vision technology points to a future where every component undergoes thorough analysis, minimizing defects and boosting operational success significantly. As industries evolve, the necessity for intricate inspections increases, making high-resolution cameras indispensable for maintaining precise image quality and supporting stringent quality benchmarks.

Reducing Defect Rates Through Ultra-HD Inspection

Implementing ultra-high-definition (Ultra-HD) inspection systems is vital for reducing defect rates and improving production yields. These advanced systems enhance product quality by detecting inconsistencies more precisely during production stages. Studies show that using these systems can reduce defects by up to 30%, underscoring their profound impact on quality assurance. The regular use of high-resolution imaging not only streamlines quality processes but also saves time and resources, making them cost-effective investments for businesses striving for excellence.

Additionally, consistent Ultra-HD inspections align with evolving industry demands for robust machine vision solutions — ensuring that companies remain competitive. In sectors like automotive manufacturing, these inspections are integral in reducing discrepancies during assembly, adhering to rigorous quality standards, and preventing costly errors. By leveraging ultra-high-definition imaging systems, industries can adapt to growing demands for defect-free products, sustaining higher-quality outputs and fostering innovation. Through this approach, machine vision becomes an essential ally in enhancing productivity and operational efficiency.

Telecentric Lenses and Machine Vision Lighting Systems

Optimizing Clarity with Bar Lights and Dome Lights

Bar lights and dome lights play a crucial role in machine vision systems by ensuring optimal clarity. These lighting solutions provide uniform illumination across the object's surface, which is essential for precise imaging. By minimizing shadows and reducing highlights, bar lights and dome lights enhance accuracy in both imaging and measurement. Specifically, the reduction of shadows allows each detail to be captured correctly—a necessity in applications involving high precision measurements. Furthermore, these lighting systems complement telecentric lenses by enhancing their performance. By using tailored lighting techniques, we can greatly improve a telecentric lens's ability to deliver precise measurements, enhancing both measurement accuracy and overall operational efficiency in industrial settings.

Telecentric Lenses for Distortion-Free Measurements

Telecentric lenses are engineered for precision, maintaining consistent magnification across varying object distances to offer distortion-free measurements. This is particularly critical in industries such as semiconductor manufacturing and optical inspection, where precision is paramount. Telecentric lenses ensure that measurements remain accurate and consistent, regardless of the object's position within the field of view. By integrating telecentric lenses into imaging systems, we can enhance the depth of field significantly without sacrificing resolution. This ability to maintain image clarity across different distances makes telecentric lenses indispensable in the realm of machine vision where detailed and accurate assessments are necessary in complex manufacturing processes.

High-Speed Cameras Revolutionizing Production Lines

Achieving 3,876 FPS for Real-Time Quality Control

High-speed cameras that can capture up to 3,876 frames per second (FPS) are transforming real-time quality control on production lines. This incredible speed allows manufacturers to monitor fast-moving parts in assembly lines and identify defects that might otherwise go unnoticed at standard frame rates. Consequently, these cameras improve operational efficiency by enabling immediate detection and rectification of issues, ensuring continuous quality improvement. Machine vision cameras are rapidly becoming fundamental components in modern automation, as underscored by industry data showing an estimated market size of US$ 9,176.9 million by 2033, driven by rising demands for real-time analytics.

Motion Blur Elimination in Rapid Assembly Processes

High-speed cameras are instrumental in eliminating motion blur, a crucial aspect in maintaining image clarity during rapid assembly processes where components move at high speeds. This technology provides detailed analysis of motion dynamics, enhancing the consistency and quality of manufactured products. By capturing sharp images, engineers can efficiently pinpoint operational delays and optimize assembly lines, leading to better productivity and reduced downtime. The surge in demand for high-resolution imaging further showcases the importance of these cameras in sophisticated manufacturing environments, supporting advancements in industries ranging from automotive to electronics.

Market Growth and Automotive Sector Adoption

30.5% Market Dominance by Automotive Manufacturers

The automotive sector occupies a commanding position in the industrial automation camera market, with an impressive 30.5% market share. This significant dominance underscores the industry's ongoing shift towards automation, where camera systems are fundamental tools for tasks such as assembly line inspection and robotic guidance. As the demand for more precise and efficient production methods increases, investments in advanced imaging solutions are expected to rise. Manufacturers are particularly focused on leveraging automation technology to enhance both operational efficiency and the quality of their products.

AI-Driven Camera Systems in Engine Assembly

AI-driven camera systems are revolutionizing engine assembly processes by heightening precision and minimizing human error. These advanced systems integrate artificial intelligence to facilitate real-time decision-making, which considerably boosts assembly line productivity. By adopting AI-driven technologies, automotive manufacturers are not only improving the accuracy of their production lines but also ensuring they remain competitive in a rapidly evolving market. This strategic adoption indicates a broader trend towards leveraging technology to meet rising productivity and quality benchmarks in the automotive industry.

Future Trends in Machine Vision Technology

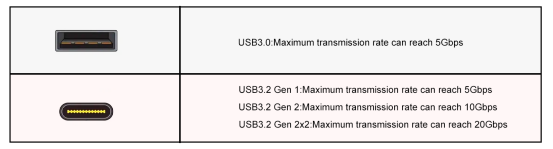

USB 3.2 Interfaces for Scalable Vision Systems

The integration of USB 3.2 interfaces in machine vision technology marks a significant advancement in ensuring faster data transfer rates, which is essential for processing high-resolution images efficiently. This upgrade not only boosts performance but also enhances the scalability of vision systems, allowing manufacturers to seamlessly expand their setups by adding more cameras and sensors. This flexibility is particularly beneficial as it accommodates the increasing demands for high-speed camera systems in industrial applications. As connectivity continues to evolve, it's anticipated that these advancements will spur further innovations, broadening the scope of machine vision applications across diverse sectors, including automotive manufacturing.

Embedded AI and Edge Processing Advancements

Embedded AI in cameras and vision systems is transforming how images are processed by enabling real-time, on-the-fly analysis, which significantly reduces latency and improves system response times. These advancements play a crucial role in edge processing, where localized decision-making is vital for real-time applications such as factory automation and production line monitoring. By integrating AI-driven technologies, industries can enhance efficiency, making timely and accurate decisions without relying on traditional, centralized computational methods. As the trend toward automation intensifies across various sectors, embedded AI and edge processing are poised to become standard components in machine vision setups, driving forward the future of industrial automation.