How Are Industrial Cameras Triggered In Vision System?

Today, let’s learning what methods can be used to trigger an industrial camera to take a photo? Continuous capture or controlled modes?

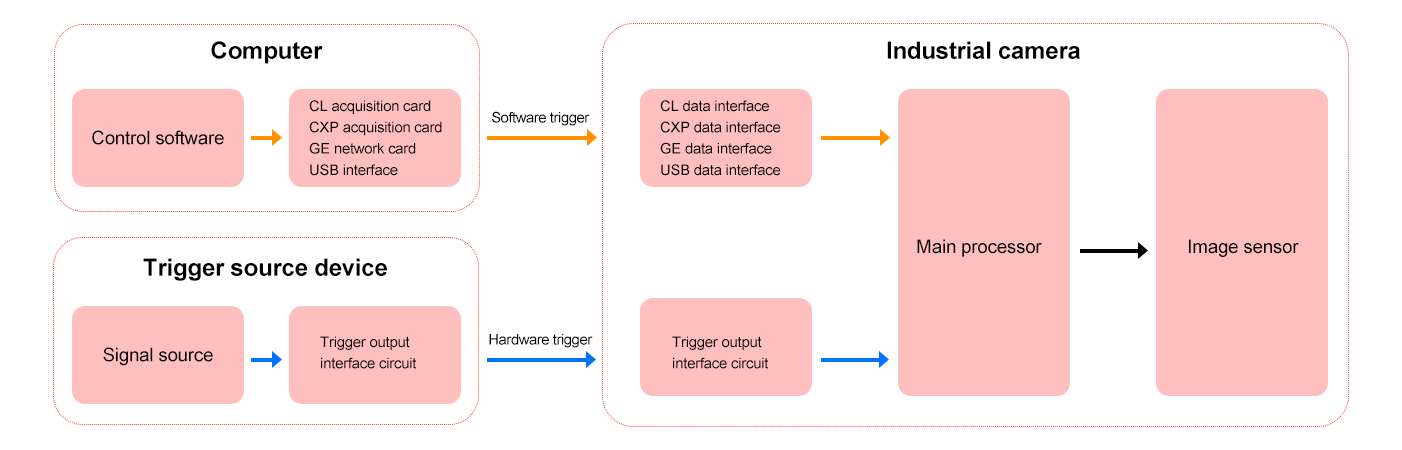

At first, let’s clarify the triggering methods for industrial cameras. The methods generally fall into two categories: hard triggering and soft triggering.

1.Hard Triggering

Hard triggering involves sending an electrical signal to the industrial camera, typically generated by a photoelectric sensor when it detects an object or by a PLC (Programmable Logic Controller) when a servo motor reaches a specific position. Industrial cameras are equipped with dedicated trigger ports that support both high-level and low-level signals. Leading camera brands also allow configuring trigger modes such as rising edge, falling edge, or continuous capture.

Hard triggering is widely used in most applications due to its simplicity and pre-configured camera interfaces.

2.Soft Triggering

Soft triggering relies on an upper computer sending a string command via communication protocols (e.g., TCP/IP, RS-232) to instruct the industrial camera to capture an image. Its advantage lies in scenarios requiring complex workflows or frequent template switching, as the industrial camera can dynamically adapt to different programs based on received commands.

After learning the differences between hard triggering and soft triggering, let’s answer the initial question. Which one is better to trigger an industrial camera? Continuous capture or controlled modes? Continuous images capture would overload the CPU and increase the risk of false detections. Instead, ontrolled modes is better to trigger the industrial cameras, cameras are triggered once per object when it reaches the designated position, ensuring efficient and reliable processing.