Application of Machine Vision Systems in Detecting Fruit Rot

In the global fruit supply chain, post-harvest loss due to rot remains a critical challenge, with statistics indicating that up to 25% of fresh fruits are discarded annually due to undetected decay during sorting and storage. Traditional fruit rot detection methods, relying on manual inspection, are not only labor-intensive and time-consuming but also prone to human error—especially when dealing with large volumes of produce or early-stage rot that is visually subtle. To address these limitations, machine vision systems (MVS) have emerged as a transformative technology, leveraging advanced imaging, computer vision, and machine learning algorithms to enable fast, accurate, and non-destructive rot detection.

1. Technical Fundamentals of the Machine Vision Detection System

The core objective of the project is to develop a system that can automatically capture fruit surface information, analyze visual features associated with rot, and classify fruits as "sound" or "rotten" with high precision. The system’s architecture is built around three key components: imaging hardware, image preprocessing modules, and rot classification algorithms.

1.1 Imaging Hardware Setup

To ensure comprehensive data collection, the project employs a multi-sensor imaging platform, including:

High-resolution RGB cameras: Capturing color information, as rot often manifests as discoloration (e.g., brown spots on apples, gray mold on strawberries).

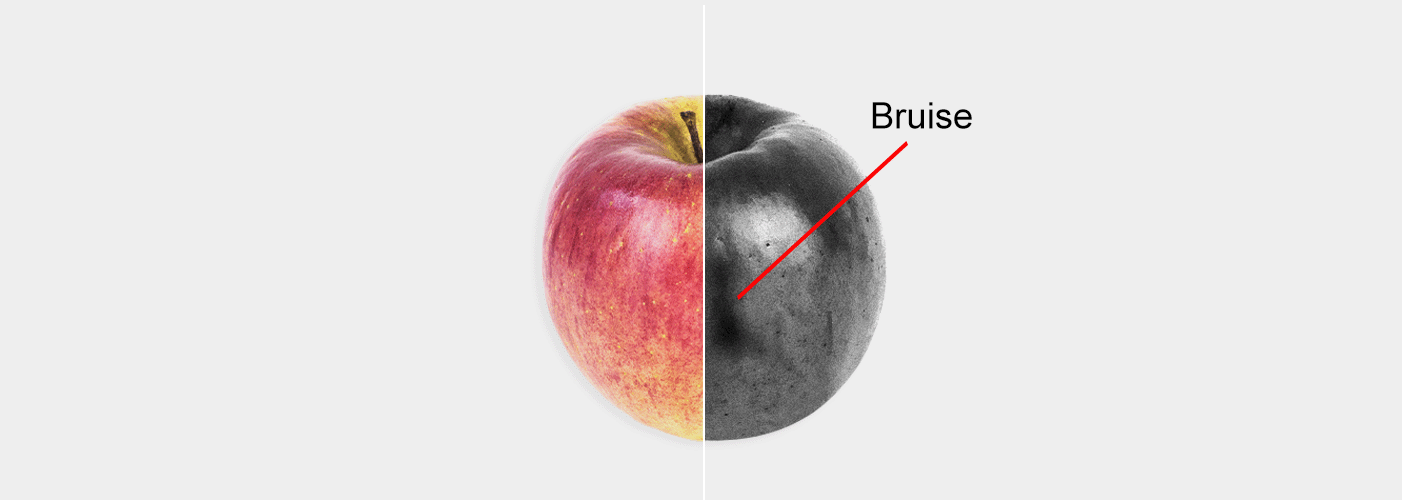

Near-infrared (NIR) cameras: Detecting internal decay that may not be visible on the surface—for instance, core rot in pears or bruise-induced rot in peaches, which alters the fruit’s spectral reflectance in the NIR range.

Controlled lighting systems: LED panels with adjustable intensity and wavelength to minimize shadows, glare, and ambient light interference, ensuring consistent image quality across different fruit varieties (e.g., glossy cherries vs. matte avocados).

1.2 Image Preprocessing: Enhancing Feature Visibility

Raw images often contain noise (e.g., dust on fruit surfaces, lighting inconsistencies) that can obscure rot-related features. The project’s preprocessing pipeline includes three critical steps:

Noise Reduction: Applying Gaussian filtering to smooth out high-frequency noise while preserving edge details of potential rot spots.

Color Space Conversion: Transforming RGB images to the HSV (Hue-Saturation-Value) color space, as hue and saturation channels are more sensitive to color changes caused by rot than the standard RGB channels. For NIR images, converting to grayscale and applying histogram equalization to enhance contrast between healthy and decayed tissue.

Segmentation: Using thresholding and edge detection algorithms (e.g., Canny edge detector) to isolate the fruit from the background and segment potential rot regions. For example, a threshold on the hue channel can identify brownish rot spots on green apples by distinguishing them from the fruit’s healthy green hue.

2. Project Workflow: From Fruit Input to Sorting Output

The machine vision detection system operates as an integrated part of a fruit packing line, following a seamless workflow:

Fruit Feeding: Fruits are loaded onto the conveyor belt, which moves them to the imaging station at a constant speed (adjustable based on fruit size, e.g., 0.5 m/s for apples, 0.3 m/s for small strawberries).

Image Capture: When a position sensor detects a fruit entering the imaging zone, the RGB and NIR cameras capture 3–5 images of the fruit from different angles.

Real-Time Processing: The preprocessing pipeline processes the images in < 0.5 seconds, and the classification model generates a rot status prediction (sound/early rot/severe rot) with a confidence score (e.g., 98% confidence for severe rot).

Sorting Action: Based on the prediction, the system sends a signal to a pneumatic actuator or robotic arm at the end of the conveyor belt. Sound fruits are directed to the "packing" line, early rot fruits are routed to a "quality control" station for manual recheck (to minimize false positives), and severe rot fruits are diverted to a "waste" bin.

Data Logging: The system records each fruit’s ID, images, classification result, and confidence score in a cloud-based database. This data is used to retrain the classification model periodically, improving accuracy as more data is collected.

3. Real-World Application and Performance: Case Studies

3.1 Apple Rot Detection

Accuracy: The system achieved 96.2% accuracy in detecting rot (vs. 82.5% for manual inspectors), with a false positive rate of only 2.1% (manual inspection had a 7.8% false positive rate).

Speed: The system processed 120 apples per minute, compared to 40 apples per minute per manual inspector—reducing labor costs by 67%.

Early Detection: The NIR camera enabled detection of internal core rot in apples 5–7 days earlier than manual inspection, allowing farms to sort affected fruits before rot spreads during storage.

3.2 Strawberry Rot Detection

Challenge: Strawberries are delicate and prone to surface mold (e.g., Botrytis cinerea) that is often missed by manual inspectors due to small size.

Result: The system’s high-resolution RGB cameras and CNN model detected mold spots as small as 2 mm in diameter, achieving 94.8% accuracy. This reduced post-harvest loss by 30% compared to the farm’s previous manual sorting process.

3.3 Mango Rot Detection

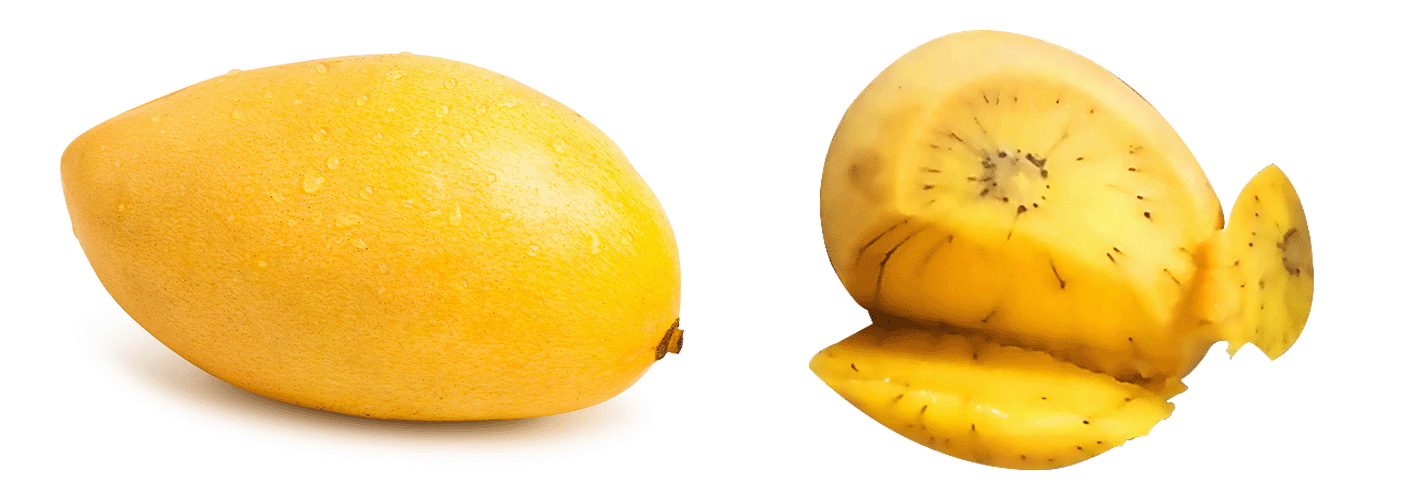

Challenge: Mangoes often develop "stem-end rot" that starts at the stem (a less visible area during manual inspection) and spreads inward.

Result: The system’s multi-angle imaging (including a bottom camera focused on the stem) and NIR analysis detected stem-end rot with 95.5% accuracy, helping the packing facility avoid rejected shipments to export markets (where rot-free mangoes are a strict requirement).

4. Challenges and Future Directions

While the project has demonstrated strong performance, several challenges remain to be addressed:

Variability in Fruit Varieties: The current model performs best on common varieties but struggles with rare or region-specific fruits (e.g., durians, lychees) due to limited training data. Future work will involve expanding the dataset through collaborations with global farms.

Environmental Interference: Humidity in packing facilities can cause condensation on camera lenses, affecting image quality. The project team is developing waterproof camera enclosures with anti-fog coatings to mitigate this issue.

Cost Accessibility: The initial setup cost (≈ $50,000 for hardware and software) may be prohibitive for small-scale farms. Future iterations will focus on low-cost alternatives, such as using smartphone cameras paired with edge computing devices (e.g., Raspberry Pi) to reduce costs by 60%.

5. Conclusion

The machine vision system project for fruit rot detection represents a paradigm shift in post-harvest quality control, addressing the inefficiencies and limitations of manual inspection. By combining advanced imaging, real-time image processing, and machine learning, the system delivers fast, accurate, and non-destructive rot detection—reducing post-harvest loss, lowering labor costs, and ensuring consistent fruit quality for consumers. As the technology evolves to become more accessible and adaptable to diverse fruit varieties, it has the potential to transform the global fruit supply chain, promoting sustainability and food security in an era of growing demand for fresh produce.