White, Blue, Red, and Green Lighting in Machine Vision

In machine vision systems, the color of the lighting is not chosen arbitrarily—selecting the right one can make defects clearly stand out, while the wrong one can make even the most advanced algorithms struggle to recognize features. Many people overlook the impact of lighting color, leading to inconsistent inspection accuracy.

Today, we will explain the applications of four core lighting colors and one contrast strategy to help quickly select the right lighting.

Ⅰ. White Light: Suitable for 80% of General Scenarios

White light covers the full visible spectrum (380–750 nm), accurately reproducing the true colors of objects. It is the most versatile lighting option and serves as the "default choice" in visual inspection.

1. Key Advantages:

Uniform spectrum and comprehensive detail rendering, eliminating the need to worry about material compatibility—whether for plastic, metal, or paper products, white light can capture clear baseline images.

2. Applicable Scenarios:

Baseline testing in the initial inspection phase (evaluate effects under white light first, then adjust), mixed-category product inspection (e.g., inspecting both plastic and metal parts on the same production line), and scenarios requiring color difference detection (e.g., food color inspection).

Note:

When unsure which color to choose, start with white light. It can handle 80% of general inspection scenarios.

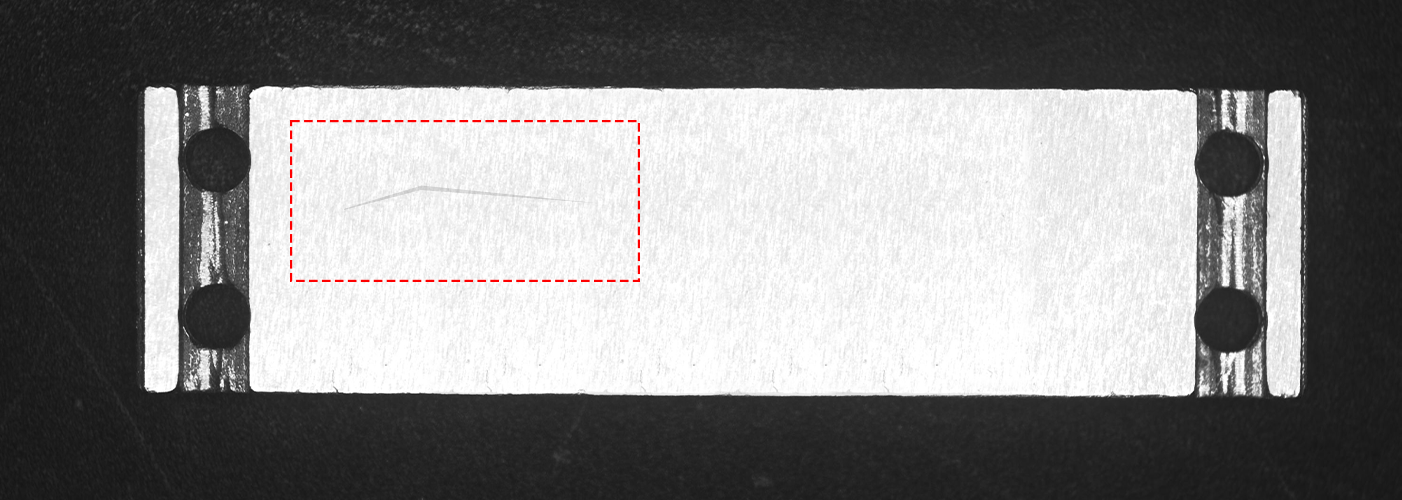

Ⅱ. Blue Light: Amplifying Tiny Defects

Blue light has a short wavelength (450–495 nm) and strongly scatters when interacting with fine structures (e.g., scratches, particles), making it ideal for highlighting micro-defects on highly reflective materials.

1. Key Advantages:

Suppresses specular reflection on metals (e.g., prevents glare on stainless steel surfaces), creating strong contrast for defects like scratches and dents.

2. Applicable Scenarios:

Surface inspection of metal parts (e.g., scratches on automotive bearings, dents on smartphone frames), detection of tiny impurities on glass surfaces, and scenarios requiring precise edge localization (e.g., chip pin alignment).

Note: Blue light can be harsh on the eyes; protective glasses must be worn during operation.

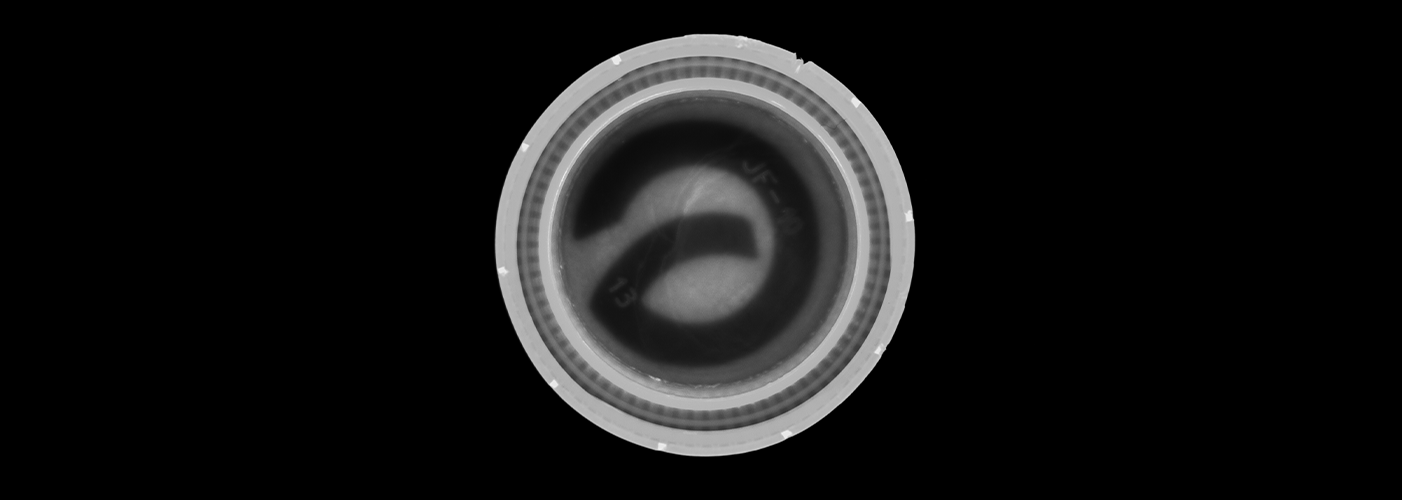

Ⅲ. Red Light: Strong Penetration Capability

Red light has a longer wavelength (620–750 nm), enabling it to penetrate certain dark or semi-transparent materials. It is suitable for inspecting "features inside or beneath surfaces."

1. Key Advantages

Not absorbed by dark materials, allowing it to penetrate surfaces and reveal underlying features—e.g., making characters visible through dark plastic bottles.

2. Applicable Scenarios

Reading characters on dark liquid bottles (e.g., oral medicine bottles, ink bottles), detecting internal bubbles in semi-transparent colloids (e.g., silicone, resin), and identifying impurities between layers of fabric.

Note: Red light can be harsh on the eyes; protective glasses must be worn during operation.

Ⅳ. Green Light: Suppressing Background Interference for Accurate Character Recognition

Green light has a medium wavelength (520–570 nm) and performs exceptionally well in monochrome camera systems, effectively suppressing background interference and enhancing target features.

1. Key Advantages

Provides extremely high contrast for red targets (e.g., red characters appear brighter under green light) and can "neutralize" green backgrounds (e.g., green bottle caps appear darker under green light, making white characters stand out).

2. Applicable Scenarios

Character recognition on packaging labels (e.g., white batch numbers on green bottle caps), detection of red defects (e.g., white impurities on red rubber parts), and target extraction in cluttered backgrounds (e.g., part positioning on green conveyor belts).

Note: Green light can be harsh on the eyes; protective glasses must be worn during operation.

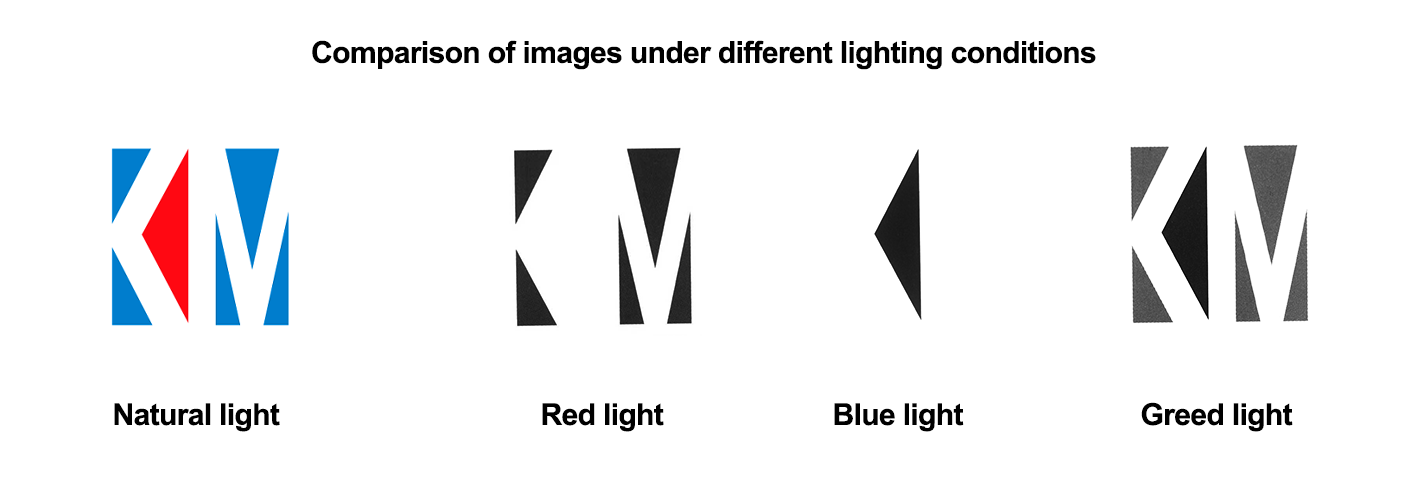

Ⅴ. Key Strategy: Enhancing Contrast with "Adjacent/Complementary Colors"

After selecting the right lighting color, applying a "color contrast strategy" can double the inspection effectiveness:

1. Adjacent Color Strategy

Use a lighting color similar to the target object (e.g., green light for green parts). This brightens the target in the image and "neutralizes" distracting backgrounds—e.g., green patterns on green packaging bags appear faded under green light, avoiding interference with white QR code recognition.

2. Complementary Color Strategy

Use a lighting color opposite to the target object on the color wheel (e.g., red vs. green, blue vs. yellow). This creates strong brightness contrast—e.g., white characters on a green background appear brighter under red light, while the background darkens, significantly improving recognition success rates.

Ⅵ. Summary: Lighting Color Selection Table for Easy Reference

The core purpose of lighting color is to "enhance the contrast between the target and the background." There’s no need to overcomplicate it. Based on the material and defect type, refer to the table below and apply the adjacent/complementary color strategy to achieve optimal image quality and double algorithmic efficiency.

Lighting color selection requires comprehensive consideration of the following factors:

|

Lighting Color |

Wavelength Range (nm) |

Key Characteristics |

Typical Applications |

|

White Light |

380–750 |

Versatile, full color reproduction |

Initial testing, mixed-category inspection, color difference detection |

|

Blue Light |

450–495 |

Defect highlighting, reflection suppression |

Metal scratches, glass impurities, edge localization |

|

Red Light |

620–750 |

Strong penetration, suited for dark/semi-transparent materials |

Character reading on dark bottles, bubble detection in colloids, interlayer inspection |

|

Green Light |

520–570 |

Background suppression, high contrast |

Character recognition, red target enhancement |