From Human Error to AI Precision: How Machine Vision is Revolutionizing PCB Quality Control

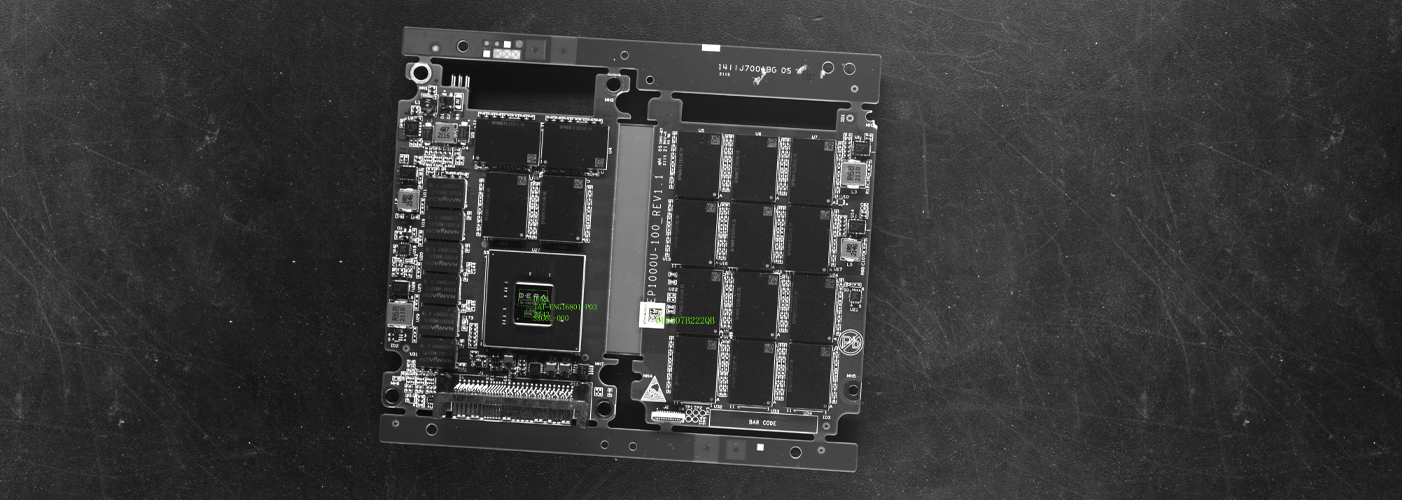

In the fast-paced world of electronics manufacturing, the printed circuit board (PCB) is the unsung hero, the "mother of all electronic products". From smartphones to servers, every device relies on these intricate circuit boards. But with the demand for flawless products at an all-time high, how can manufacturers guarantee quality at scale? The answer lies in

machine vision, a technology that is transforming quality control and making manual inspection a thing of the past.

The Power of Light: How Vision Systems 'See' Defects

At the core of any machine vision system is the

light source. It's the most critical component, as the right lighting can make or break a defect detection system. By carefully selecting a light source, manufacturers can make defects stand out, simplify image processing, and overcome environmental interference. This isn't just about illuminating a PCB; it's about making specific features—like a tiny scratch or a misplaced component—jump out to the camera.

Here's how different lighting techniques are used for various inspection tasks on a PCB:

1. Finding Mark Points: Mark points are reference points on a PCB used for positioning. A

ring light is often used for this task because it fully illuminates the points, making them appear brighter and easier to identify against the background.

2. Reading QR Codes: To read a QR code, a coaxial light is used. This type of lighting creates a high-contrast image where the black lines of the code absorb the light and the background reflects it, making the code's pattern crisp and clear for the system to read.

3. Checking for Components: A combination of dome and coaxial light is used to check for the presence or absence of components. This setup provides uniform, multi-directional light that minimizes reflections from shiny surfaces, like glue, ensuring that components underneath are clearly visible11.

4. Spotting Defects: A high-intensity coaxial light is perfect for detecting surface flaws like scratches or holes. The defects scatter or absorb the light, making them appear as dark spots against the bright, reflective surface of the normal PCB.

The Future is Flawless

The use of machine vision in PCB manufacturing is not just an application; it's a strategic advantage. It allows for faster, more accurate, and more reliable quality control than any human inspector could achieve. As electronics become more complex and the demand for perfection grows, so too will the need for advanced machine vision technology. By embracing these systems, manufacturers can ensure their products are of the highest quality, reduce waste, and stay ahead in a competitive market.

Ready to elevate your quality control? Dive deeper into the possibilities of machine vision and discover how the right lighting can illuminate the path to flawless production.