Filters, Polarizers, and Prisms In Machine Vision

I. Filters: Enhancing Feature Contrast and Filtering Ambient Light Interference

A filter, simply put, is an optical component that restricts the passage of light within specific wavelength ranges. It is mounted in front of a camera lens to control the type of light entering the camera. More professionally, filters can block unwanted spectral components, allowing only light of specific wavelengths to pass through. This effectively eliminates interference from ambient light.

For example, during red backlight testing, the product surface may be affected by external light sources, causing reflections or over-illumination that compromises detection accuracy. In such cases, installing a filter in front of the lens can block all light except red light. As a result, the image contours become sharper, and feature contrast is significantly enhanced. This approach not only effectively avoids interference from background light but also enhances the visibility of target object features, making visual detection more precise.

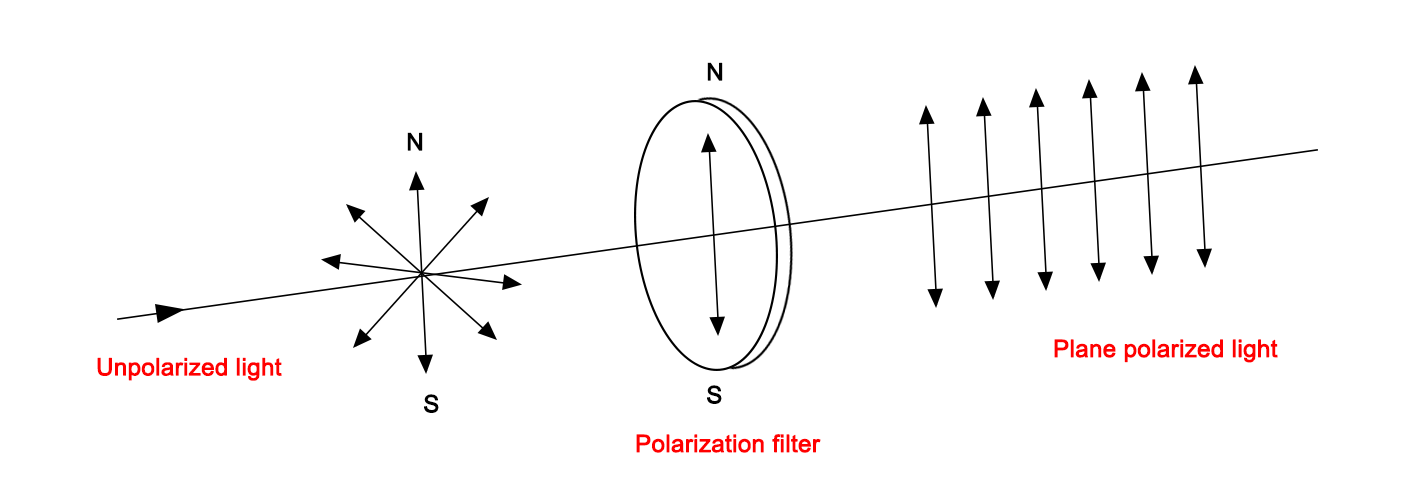

II. Polarizers and Polarizing Lenses: Eliminating Glare and Improving Surface Inspection

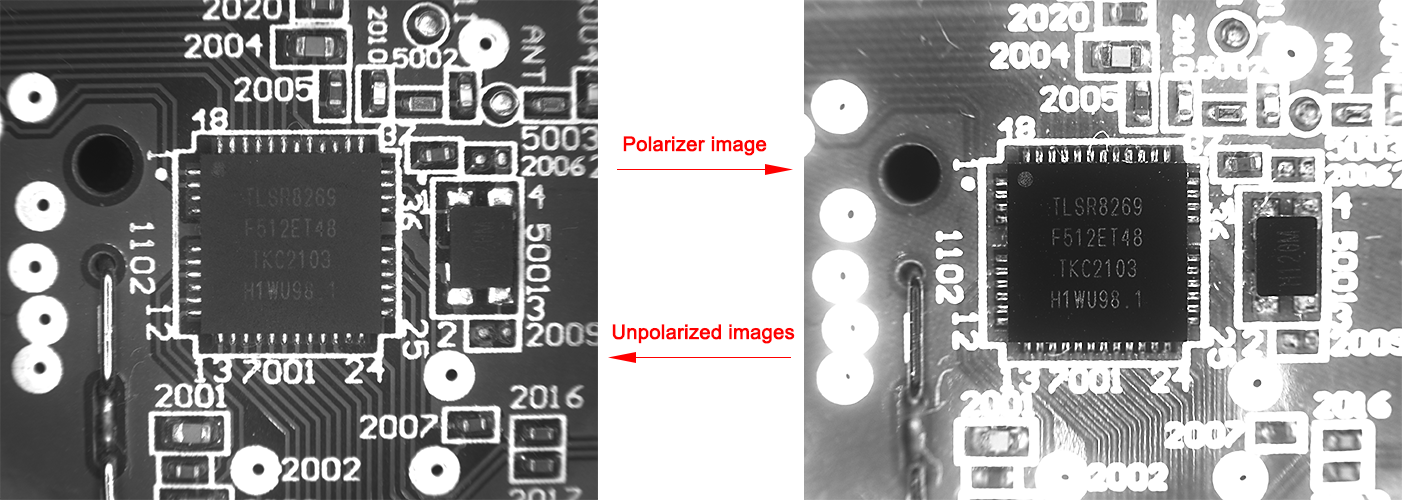

In certain scenarios, glare can severely impact the extraction of surface features of products. This is especially true for metallic, glass, or other highly reflective surfaces, where a common challenge arises: although the camera can capture an image, the smooth surface reflects a significant amount of ambient light, resulting in an image without clear feature contours. One solution to this problem is using a combination of polarizers and polarizing lenses.

Polarizers can alter the polarization direction of light entering the lens, thereby reducing or eliminating the impact of reflected light on the image. By adjusting the knob of the polarizing lens, the polarization direction of the light can be modified, effectively suppressing glare.

For instance, suppose we are inspecting the surface of an electrode sheet. Due to the highly reflective nature of the electrode surface, the original contours may be completely drowned in bright reflections. Here, the combination of polarizers and polarizing lenses can help remove excess reflected light, making the surface details of the product clearer. Ultimately, the processed image exhibits more prominent features and clearly visible contours, greatly enhancing detection accuracy.

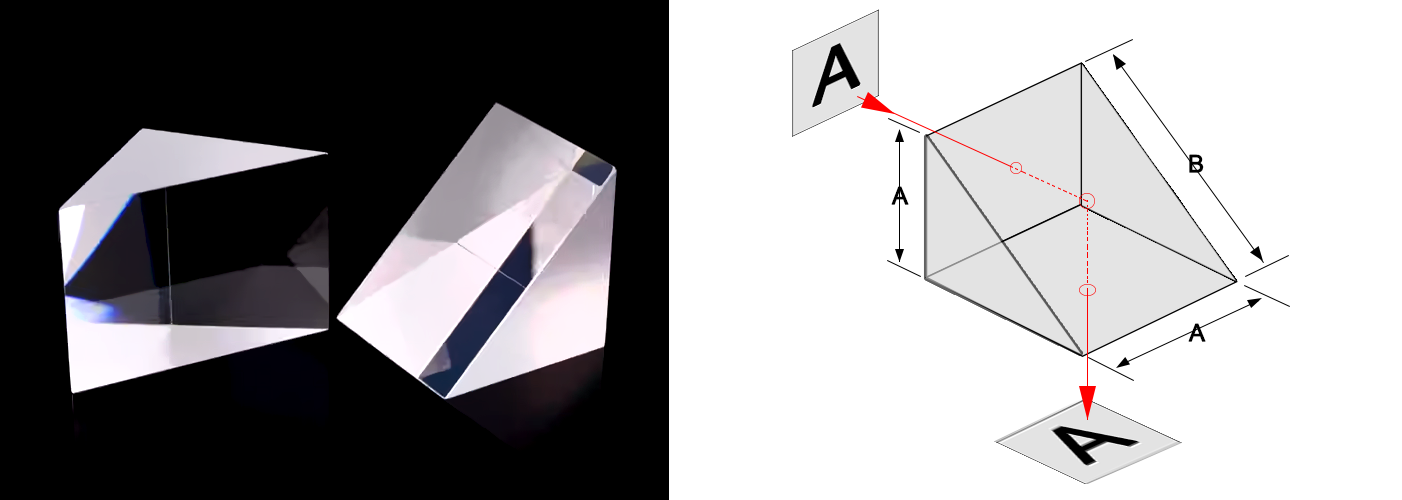

III. Prisms: Redirecting Light to Overcome Spatial Constraints

In some compact industrial inspection environments, space constraints may prevent the camera and product from being placed in an ideal position. In such cases, prisms become highly useful optical accessories. Prisms can redirect the path of light by 90 degrees, cleverly resolving spatial challenges between the camera and the object being inspected.

For example, when inspecting the solder joints on all four sides of a chip, directly capturing images of each side may be limited by the space between the camera and the chip. By using multiple prisms, a 90-degree flip of the image can be achieved, allowing the camera to capture side images of the object. This way, the camera only needs to capture one shot to obtain images of multiple sides of the object, achieving a "one-camera, five-side" effect. This not only saves time and space but also improves the efficiency and accuracy of inspections.

Filters, polarizers, polarizing lenses, and prisms—these optical accessories play a crucial role in machine vision by effectively addressing ambient light interference, reflected light issues, and optimizing inspection spatial arrangements. They make image acquisition more efficient and precise, proving indispensable in close-range inspections and other vision detection applications.