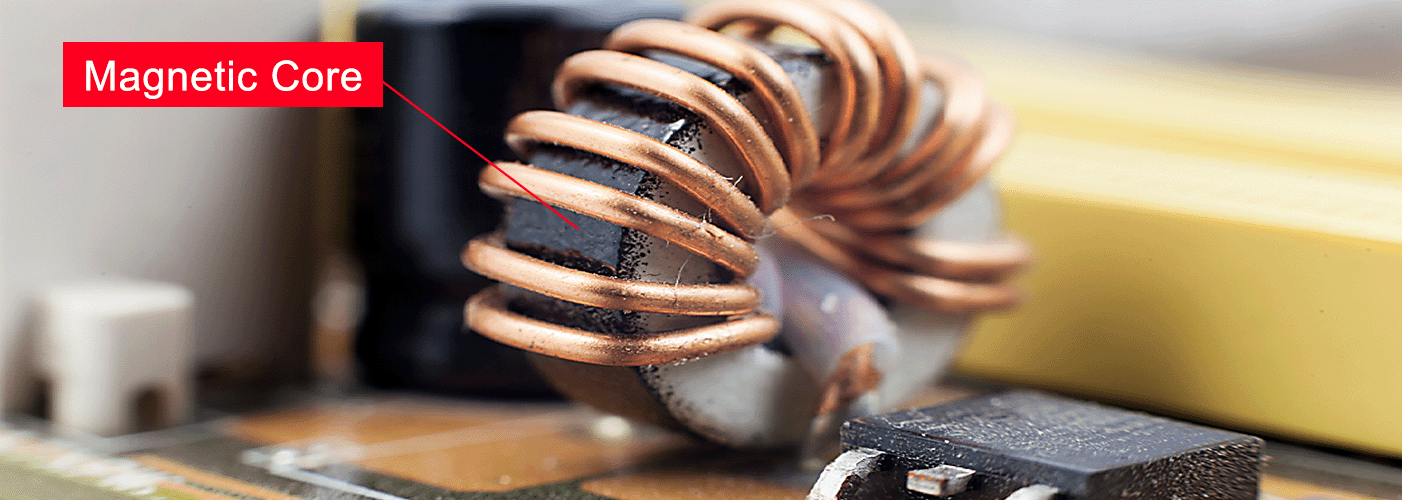

Enhancing Quality Control: Magnetic Core Surface Defect Detection with Machine Vision

In the world of electronics, even the smallest component can determine the reliability of an entire system. Magnetic cores—integral to countless electronic devices—must maintain flawless quality to ensure performance and safety. However, during production, transportation, or storage, these cores are vulnerable to cracks, chips, scratches, and stains. Left undetected, such surface defects can degrade magnetic properties and cause equipment failures.

This is where machine vision technology steps in, offering manufacturers a faster, more accurate, and highly reliable solution for defect detection.

Why Detecting Magnetic Core Defects Matters

Magnetic cores are not just passive parts—they are the backbone of many high-performance circuits. Their surface integrity directly affects:

Performance reliability – Defects can compromise magnetic efficiency.

System safety – Faulty cores can cause critical electronic malfunctions.

Production efficiency – Early detection minimizes waste and rework.

By implementing precise inspection systems, manufacturers can protect product quality and reinforce their reputation in the market.

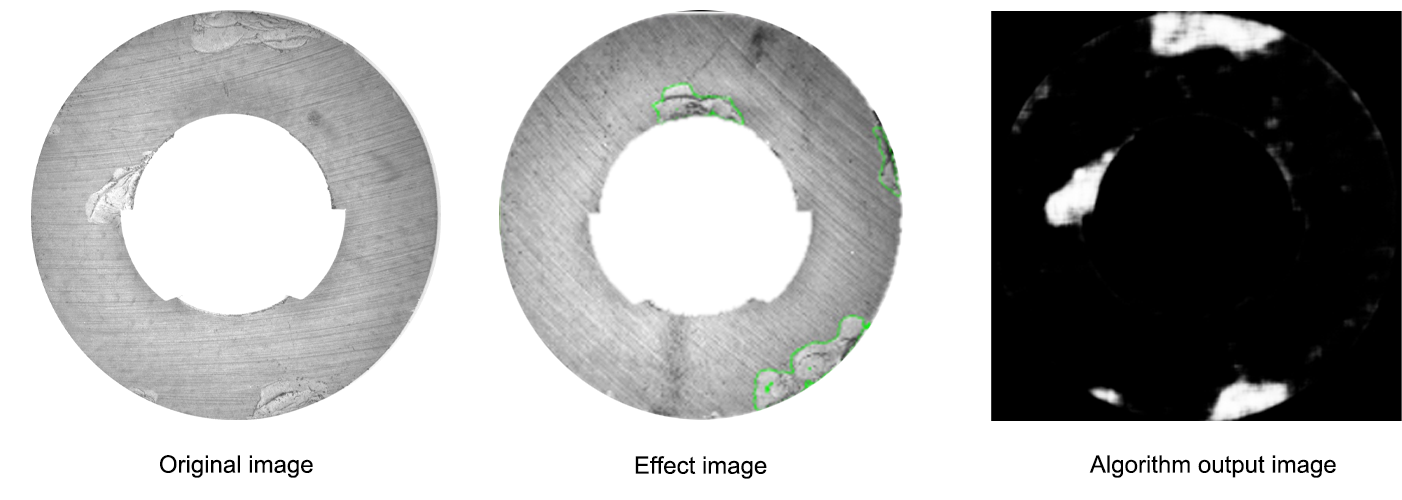

The Case Study: Ring Lighting for Accurate Detection

A recent defect detection case highlights how advanced lighting solutions make inspection faster and more effective.

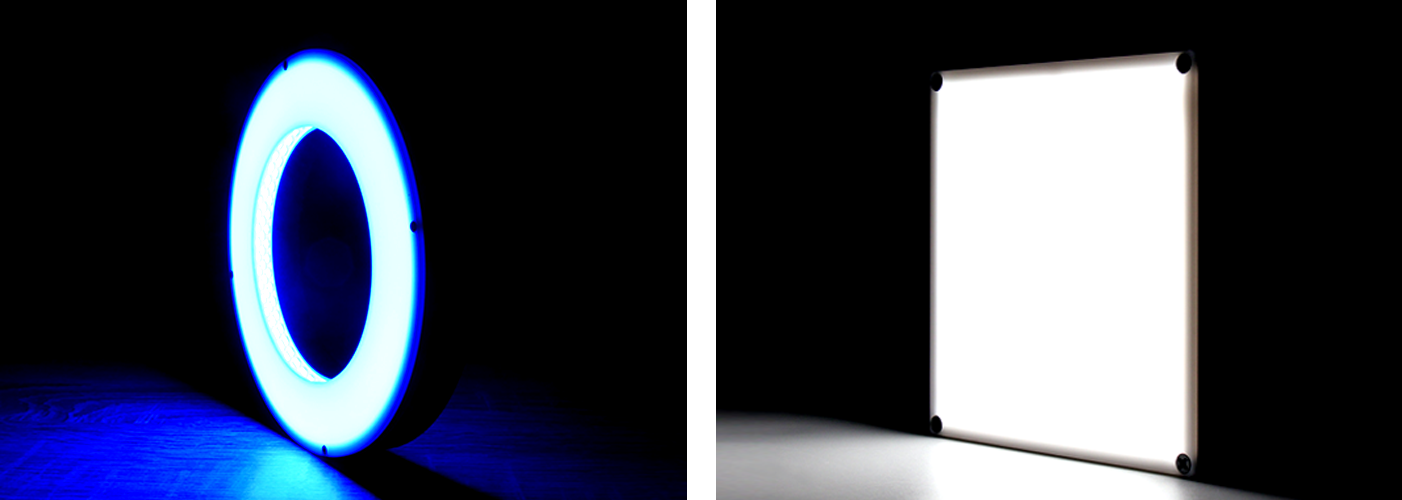

Lighting Setup

Ring light source combined with a backlight source.

This setup allows defects to be easily distinguished from normal surfaces through color contrasts.

Results

Cracks and chips: Appear with distinct color differences compared to intact areas.

Scratches and stains: Become more visible under multi-color illumination.

Enhanced algorithm accuracy: Clearer images simplify machine vision analysis and speed up processing.

The result is a robust system where defects stand out visually, ensuring accurate detection without slowing production lines.

Hifly : A Leader in Machine Vision Lighting

Hifly has specialized in the development and manufacturing of machine vision lighting systems. Today, Hifly is recognized as one of China’s most comprehensive and cost-effective manufacturers in the field. Guided by a philosophy of craftsmanship, the company continues to innovate, providing high-quality, value-driven products that support smarter manufacturing worldwide.

Conclusion & Call to Action

Magnetic core surface defect detection is no longer a challenge thanks to advanced machine vision lighting. By leveraging multi-color, multi-angle illumination, manufacturers can achieve:

Faster detection

Higher accuracy

Greater production efficiency

If you’re looking to strengthen your quality control with cutting-edge inspection solutions, explore Hifly machine vision lighting systems today and see how precision lighting can transform your manufacturing process.