मशीन विज़न प्रकाश स्रोत कैसे चुनें: परफेक्ट प्रकाश स्त्रोत का गाइड

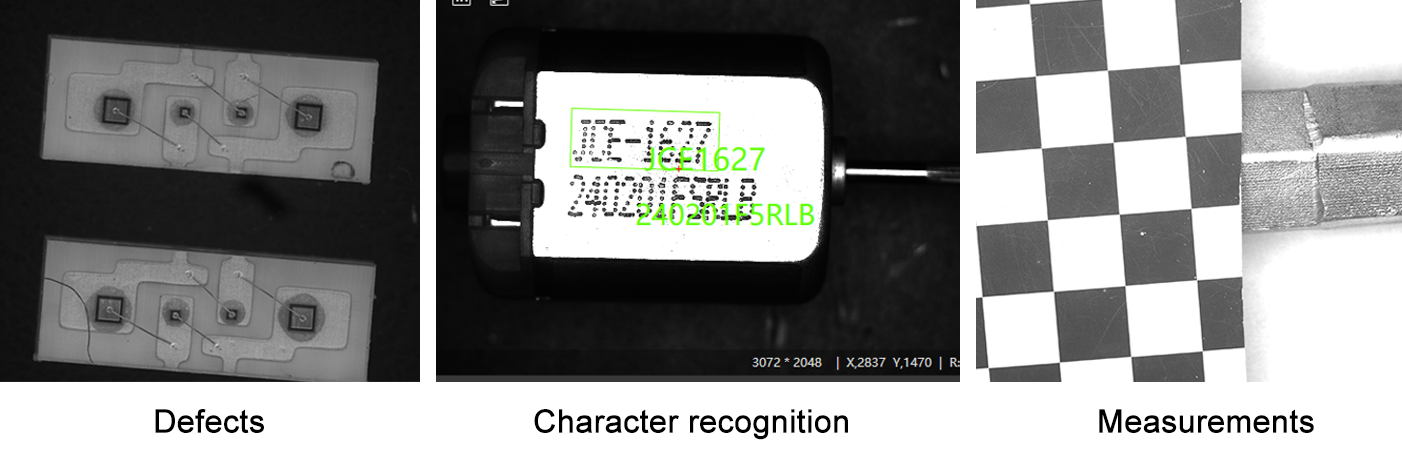

मशीन विज़न के तेज़ गति वाले दुनिया में, आपका कैमरा सबसे बड़ा प्रदर्शन कर सकता है, लेकिन वास्तविक जादू सही प्रकाश स्रोत के साथ होता है। सही प्रकाश प्रदान करना आपके सिस्टम की क्षमता को बनाने या तोड़ने में मदद कर सकता है, चाहे वह खराबी पहचानने, कोड पढ़ने या भागों को मापने के लिए हो। लेड से लेकर रिंग लाइट्स तक के विकल्पों की अपेक्षा करते हुए, सबसे अच्छा प्रकाश स्रोत चुनना एक प्रदर्शन के लिए सही स्पॉटलाइट खोजने की तरह है। गलत होने पर, आपको छायाओं या चमक से सामना करना पड़ सकता है; सही होने पर, आपका विज़न सिस्टम चमकता है।

इस एपिसोड में, हम आपको मशीन विज़न प्रकाश स्रोतों को कैसे चुनें, इस पर चर्चा करेंगे, जिसमें मुख्य कारक, लोकप्रिय प्रकार और व्यावहारिक टिप्स को कवर किया गया है। चाहे आप एक नई लाइन सेट कर रहे हों या मौजूदा को बेहतर बनाने की कोशिश कर रहे हों, चलिए सफलता के लिए रास्ता प्रकाशित करते हुए शुरूआत करते हैं—अभी!

मशीन विज़न में प्रकाश स्तंभ क्यों महत्वपूर्ण है

मशीन विज़न सिस्टम स्पष्ट और संगत छवियों पर निर्भर करते हैं ताकि वे ऑब्जेक्ट्स का विश्लेषण कर सकें। एक कैमरा केवल उस चीज़ को 'देख सकता है' जो प्रकाश द्वारा प्रकट होती है, और बदसूरत प्रकाशन खराबी को छूट देने या गलत मापदंडों के कारण हो सकता है। सही प्रकाश स्रोत कन्ट्रास्ट को बढ़ाता है, चमक को कम करता है और किनारे या पाठ्य के जैसे विशेषताओं को प्रमुख बनाता है। यह आपके स्वचालन को विश्वसनीय परिणाम देने का आधार है, इसलिए किसी भी परियोजना के लिए चयन एक महत्वपूर्ण कदम है।

आइए देखें कि पूर्ण प्रकाश का चयन करते समय क्या सोचना चाहिए।

विचार करने के लिए महत्वपूर्ण कारक

सही प्रकाश स्रोत का चयन करना एक एक-आकार-फिट-सभी फैसला नहीं है। यहां तक कि जो ध्यान रखना है:

1. अनुप्रयोग का प्रकार

क्या आप फ्लैट सतहें, बेलनाकार ऑब्जेक्ट्स, या चले हुए भागों की जाँच कर रहे हैं? प्रत्येक को विवरणों को प्रभावी रूप से प्रकट करने के लिए विशिष्ट प्रकाशन की आवश्यकता होती है।

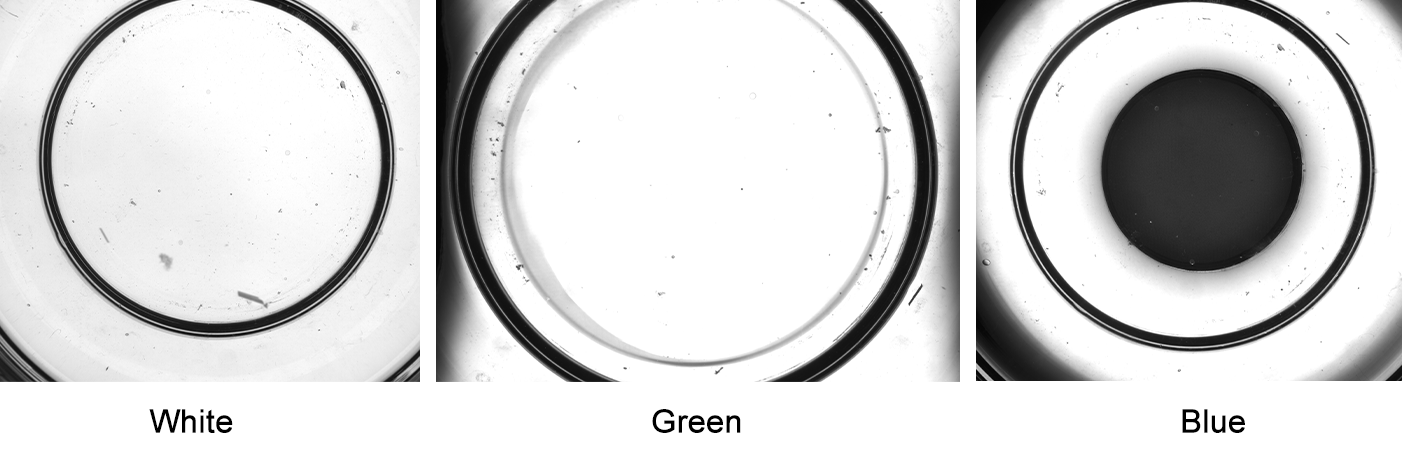

2. तरंगदैर्ध्य और रंग

विभिन्न रंग (उदा., लाल, नीला, सफेद) विशिष्ट विशेषताओं को प्रकट करते हैं। लाल प्रकाश धातु की सतहों के लिए तुलना में मदद कर सकता है, जबकि नीला प्लास्टिक की खराबियों को चमका सकता है।

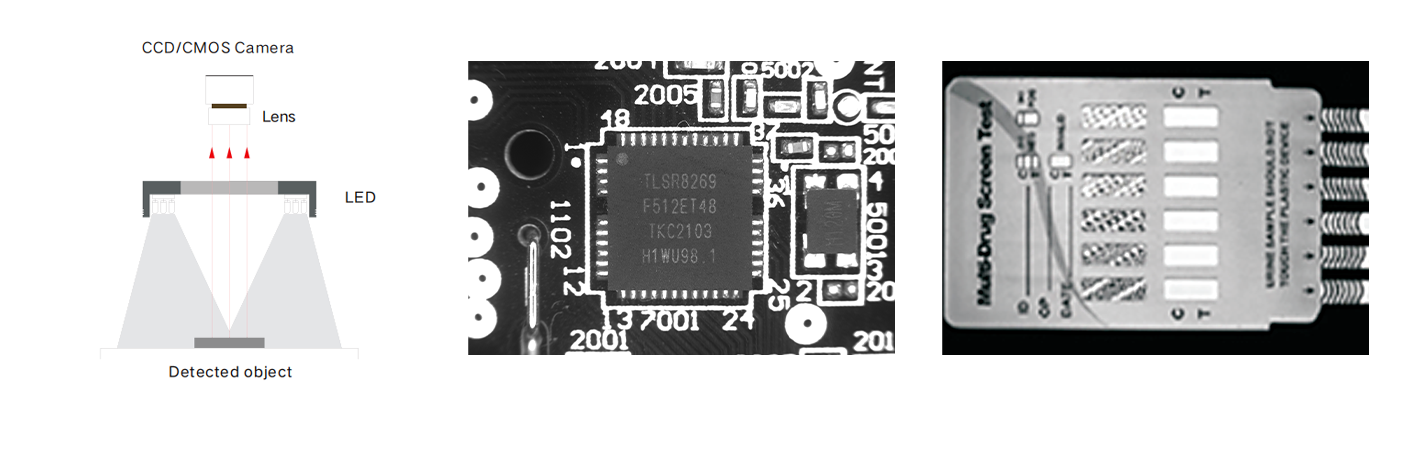

3. प्रकाशन ज्यामिति

प्रकाश का कोण और दिशा—सीधा, फ़िलोटा हुआ, या पीछे से पड़ने वाला—विशेषताओं के उपस्थित होने पर प्रभाव डालता है। सीधा प्रकाश किनारों के लिए काम करता है; फ़िलोटा हुआ प्रकाश परावर्तन को मधुर करता है।

4. तीव्रता और एकसमानता

उच्च-तीव्रता प्रकाश तेजी से चलने वाली लाइनों के लिए उपयुक्त है, जबकि समान रूप से प्रकाशित होने से गर्म बिंदुओं या छायाओं को रोका जाता है।

5. पर्यावरण

आपके कार्य क्षेत्र में धूल, गर्मी, या नमी की वजह से कठिन, बंद रोशनी के विकल्पों की आवश्यकता हो सकती है।

6. बजट और जीवनकाल

एलईडी ऊर्जा-कुशल और दीर्घायुशी होते हैं, लेकिन विशेषज्ञ रोशनियाँ शुरुआत में अधिक खर्च कर सकती हैं।

मशीन विज़न प्रकाश स्रोत के लोकप्रिय प्रकार

यहाँ सबसे आम प्रकाशन विकल्पों का सार और उनके उपयोग के बारे में जानकारी है:

1. छल्ला प्रकाश

वे कैसे काम करते हैं :वृत्ताकार प्रकाश कैमरा लेंस के चारों ओर घेरता है, जो समान रूप से रोशनी प्रदान करता है।

के लिए सबसे अच्छा : सर्किट बोर्ड या लेबल जैसी सपाट सतहों की जांच।

यह क्यों काम करता है :छायाओं को कम करता है और अधिकांश सेटअप्स में आसानी से जुड़ता है।

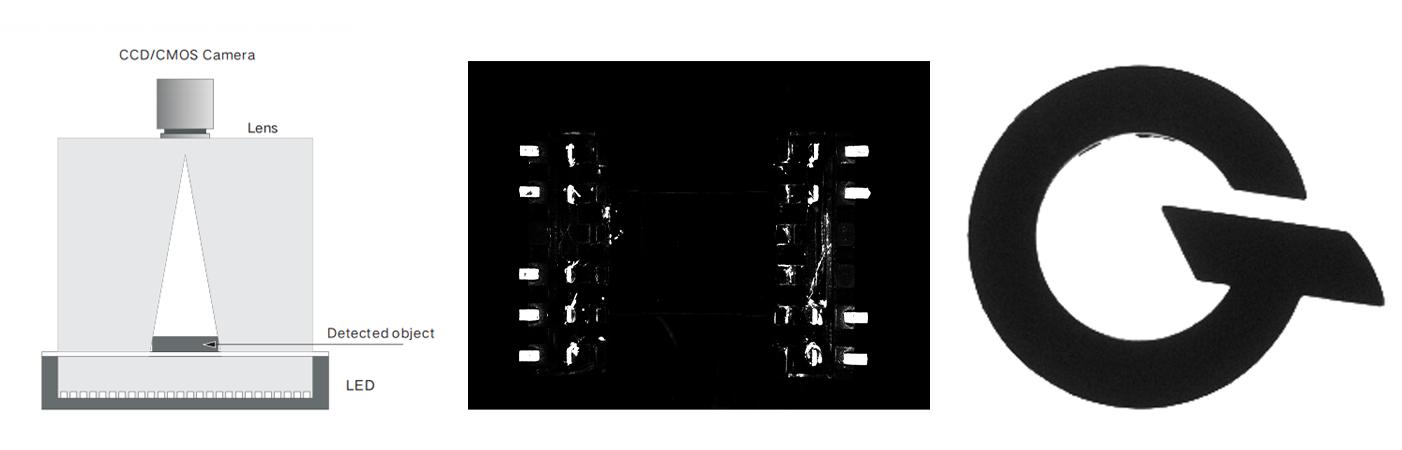

2. पीछे से प्रकाश

वे कैसे काम करते हैं :प्रकाश ऑब्जेक्ट के पीछे से चमकता है, जिससे एक सिलोहट प्रभाव बनता है।

के लिए सबसे अच्छा : डिमेंशन मापने या भागों में छेद पता करने के लिए।

यह क्यों काम करता है :सीमा पता करने के लिए उच्च तुलना प्रदान करता है।

3. बार प्रकाश

वे कैसे काम करते हैं :वस्तु के समानांतर लंबे, रेखीय प्रकाश।

के लिए सबसे अच्छा : चौड़े या चलते सतहों को स्कैन करना, जैसे कागज के रोल।

यह क्यों काम करता है : विशाल क्षेत्रों पर समान प्रकाश डालता है।

4. डोम प्रकाश

वे कैसे काम करते हैं :एक गुंबदाकार डिफ्यूज़र प्रकाश को समान रूप से फैलाता है।

के लिए सबसे अच्छा : चमकीले या प्रतिबिंबित सतहें जैसे मetal या glass।

यह क्यों काम करता है : ग्लार को कम करता है और सूक्ष्म दोषों को प्रकट करता है।

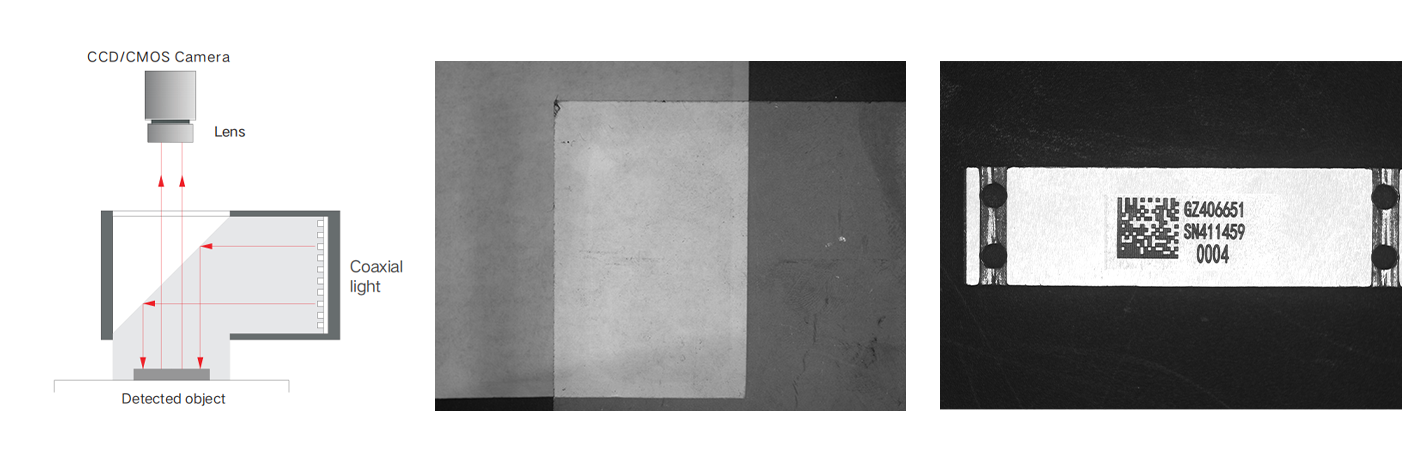

5. Coaxial Lights

वे कैसे काम करते हैं :प्रकाश एक बीम के माध्यम से प्रतिबिंबित होता है। स्प्लिटर, कैमरे की पerspective से प्रकाशित।

के लिए सबसे अच्छा : फ़लत, प्रतिबिंबित ऑब्जेक्ट्स या बारकोड पढ़ना।

यह क्यों काम करता है : चुनौतीपूर्ण सतहों पर समान प्रकाश देना विश्वसनीय रखता है।

चयन के लिए प्रायोगिक टिप्स

प्रतिबद्धता से पहले परीक्षण करें :विभिन्न प्रकाशों के तहत नमूना पार्ट्स के साथ परीक्षण करें ताकि देखें कि क्या सबसे अधिक विवरण को खोलता है।

मैच टू औद्योगिक कैमरा :अपने प्रकाश की तरंगदैर्घ्य को अपने कैमरे के सेंसर संवेदनशीलता के साथ मिलाएं।

ऑटोमेशन की सोचें :डायनामिक लाइन्स के लिए समायोज्य तीव्रता या ट्रिगर वाले प्रकाश चुनें।

एक्सपर्ट्स से सलाह लें :एक आपूर्तिकर्ता के साथ काम करें ताकि प्रकाशन आपकी विशिष्ट सेटअप के अनुसार बनाया जा सके।

उदाहरण के लिए, यदि आप 1,000 इकाइयों प्रति मिनट की दर से बोतलों की बेल्ट की जाँच कर रहे हैं, तो आपके कैमरे के साथ समन्वित एक उच्च-तीव्रता बार प्रकाश विजेता हो सकता है।

सामान्य चुनौतियाँ और समाधान

चमकीली सतहों पर चमक :प्रतिबिंब को कम करने के लिए डोम लाइट्स या पोलराइज़्ड फिल्टर्स का उपयोग करें।

असंगत प्रकाशन : प्रसारित प्रकाश या कोणों की समायोजन करें ताकि छायाओं से बचे।

गर्मी का जमाव : लंबे समय तक विश्वसनीयता के लिए हीट सिंक वाले LED प्रकाश चुनें।

सही समायोजनों के साथ, ये बाधाएँ सफलता के पथ के पदर्शक बन जाती हैं।

सही प्रकाश स्रोत का प्रभाव

एक अच्छी तरह से चुनी गई प्रकाश स्रोत केवल चित्रों को बढ़ावा नहीं देती है, बल्कि आपकी कार्यक्रम को बदल देती है:

उच्च सटीकता :स्पष्ट चित्र कमांड में दोष पत्रण में त्रुटियों की कमी होती है।

तेजी से प्रोसेसिंग :आदर्श प्रकाश बहुत सारे स्कैन की आवश्यकता को कम करता है।

लागत की बचत :कम अस्वीकृतियाँ और कम बंद रहने का समय आपकी लाभ रेखा को बढ़ाती है।

पैमाने पर वृद्धि :सही सेटअप आपकी उत्पादन मांग के साथ बढ़ता है।

आज के प्रतिस्पर्धी परिवेश में, प्रकाश संचालन एक रणनीतिक फायदा है।

मशीन विजन प्रकाशित का भविष्य

जैसे-जैसे प्रौद्योगिकी आगे बढ़ती है, स्मार्ट प्रकाशन (लाइटिंग) साथिक प्रज्वलन और AI-ड्राइवन समायोजन के साथ आने पर है। ये चुनौतियाँ अधिक बेहतर सटीकता का वादा करती हैं, जिससे अब आपके सिस्टम को अपग्रेड करने का सही समय है।

क्या आप अपनी दृष्टि को प्रकाशित करने के लिए तैयार हैं?

सही मशीन विज़न प्रकाश स्रोत का चयन आपके सिस्टम की पूरी क्षमता को खोलने का तंत्र है। चाहे यह फ्लैट जाँच के लिए एक रिंग लाइट हो या बेहतरीन मापन के लिए एक बैकलाइट, हम आपके लिए समाधान लाए हैं।

हमारे मशीन विज़न प्रकाशन विकल्पों का पता लगाएं या व्यक्तिगत परामर्श के लिए हमारे विशेषज्ञों से संबंध करें। खराब प्रकाशन के कारण अपने परिणामों को कमजोर न मानें—संपर्क करें हिफली आज ही और अपनी उत्पादन लाइन को चमकाएं!