The Light Source Used For Detecting Characters On The Product Surface

In industrial vision-based surface character inspection (e.g., production dates), coaxial light sources and bar light sources are preferred, and the specific selection should be based on the characters and the material and contrast of the product surface.

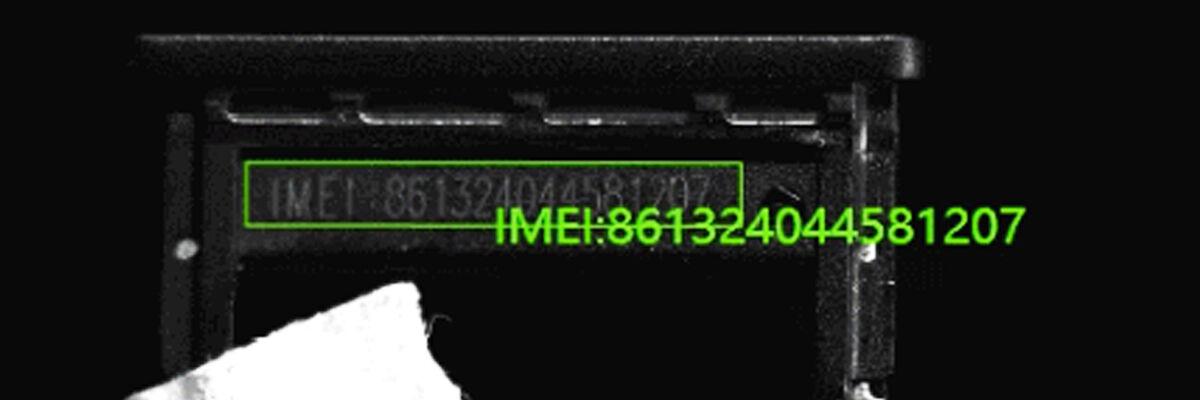

- Coaxial light source: Suitable for specular and highly reflective product surfaces (e.g., metal, plastic casings). It can eliminate reflection interference and make character edges clear and sharp.

- Bar light source: Suitable for flat and low-reflective surfaces. It can enhance the contrast between characters and the background through multi-directional combinations (e.g., 4-directional bars).

- For characters with shallow textures such as laser marking or etching, a diffuse ring light source can be selected to provide soft fill light and avoid shadow occlusion of details.

Industrial Vision Character inspection Light Source Selection Table

|

Product Surface Material |

Character Type |

|

Specular/highly Reflective (metal glass, glossy plastic) |

Inkjet-printed, screen-printed characters |

|

Matte/low-reflective Inkjet-printed characters (paper box, rubber frosted plastic) |

Laser-marked etched shallow-textured characters |

|

Transparent material (PET bottle, transparent film) |

Inkjet/heat-stamped characters |

|

Specular/highly reflective (metal glass, glossy plastic) |

Inkjet-printed, screen-printed characters |